Simple shearing test method and device for rock-concrete cement face

A shear test and concrete technology, applied in the direction of measuring devices, mechanical devices, instruments, etc., can solve the problems of complex device structure, difficult operation, inaccurate data measurement, etc., and achieve simple appearance and structure, simple test operation, and high reliability. degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

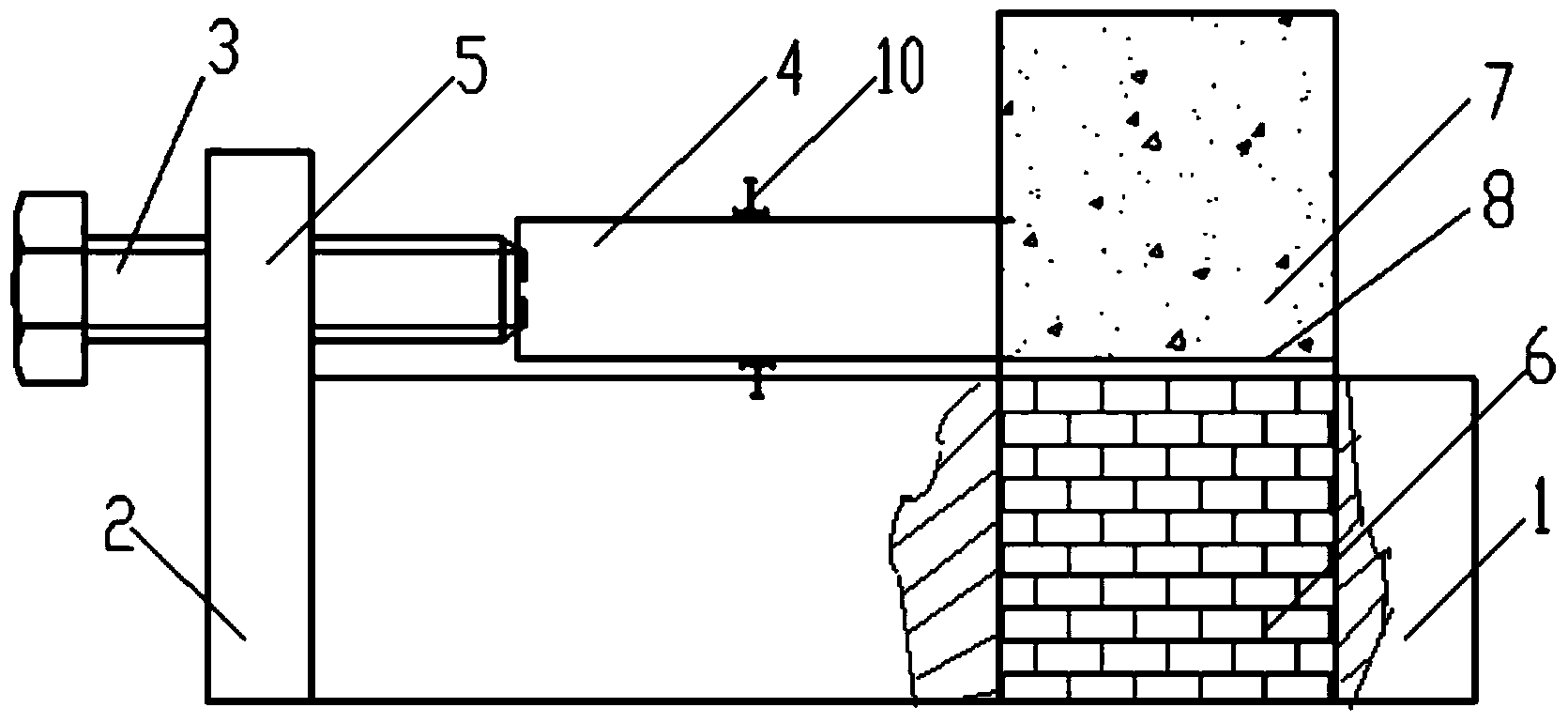

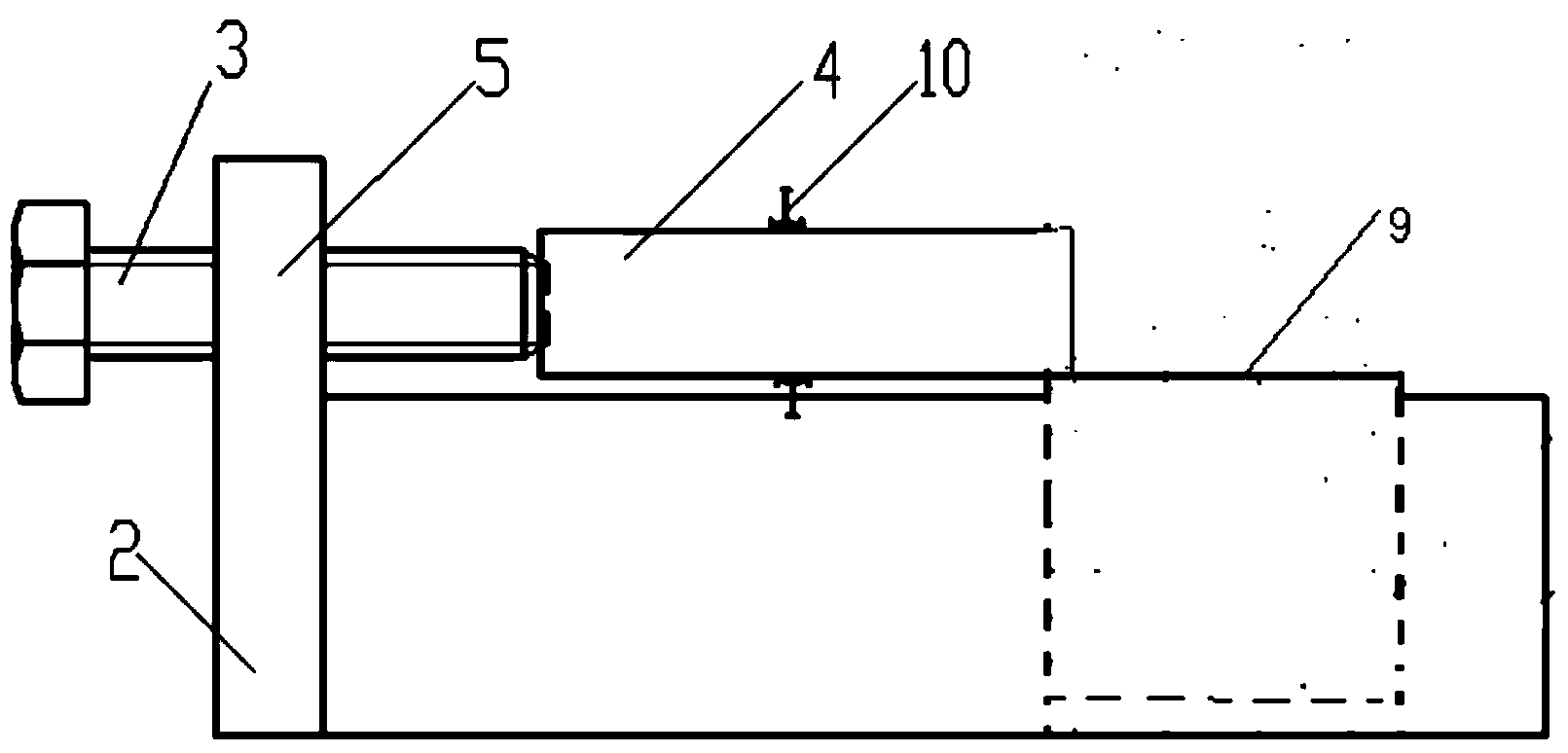

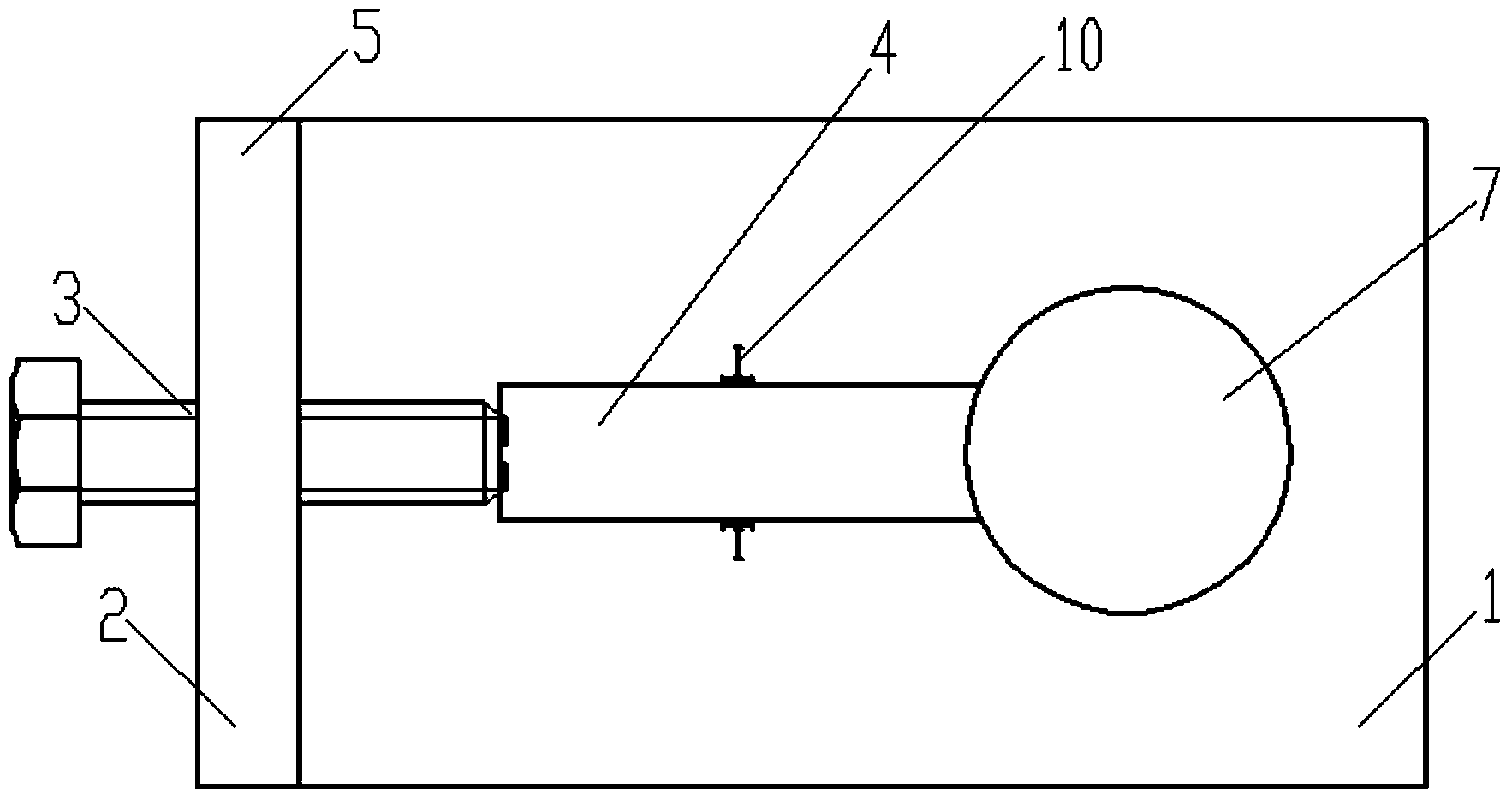

[0018] combine figure 2 and image 3 , The simple and simple shear test device includes: device base 1, connecting plate 2, force transmission screw 3, sensor 4, force transmission screw screw hole 5, base hole groove 9, strain rosette 10.

[0019] The base 1 of the device adopts a solid steel material of 169mm×100mm×47mm, and a φ49.8mm base hole 9 is opened at the right end of it for fixing the test piece. The left end is welded to the connecting plate 2, and the weld seam is ground and polished. An M16 bolt hole 5 is opened on the center of the connecting plate at a distance of 50 mm from the top of the plate, and the force transmission screw 3 passes through the bolt hole 5 and is centered with the sensor 4 to apply a shear load.

[0020] The sensor 4 is the main measuring part of this device. It is made of Q245 steel. Realize the seamless connection between the sensor and the outer edge of the test piece. The surface of the sensor should be ground and polished, and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com