Gas pressure sensor assembly structure

A technology of air pressure sensor and assembly structure, which is applied in the field of sensors, can solve the problems of sensor structure damage, affecting sensor detection accuracy, etc., and achieve the effects of improving reliability, preventing rotation, and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in detail below with reference to the drawings and examples.

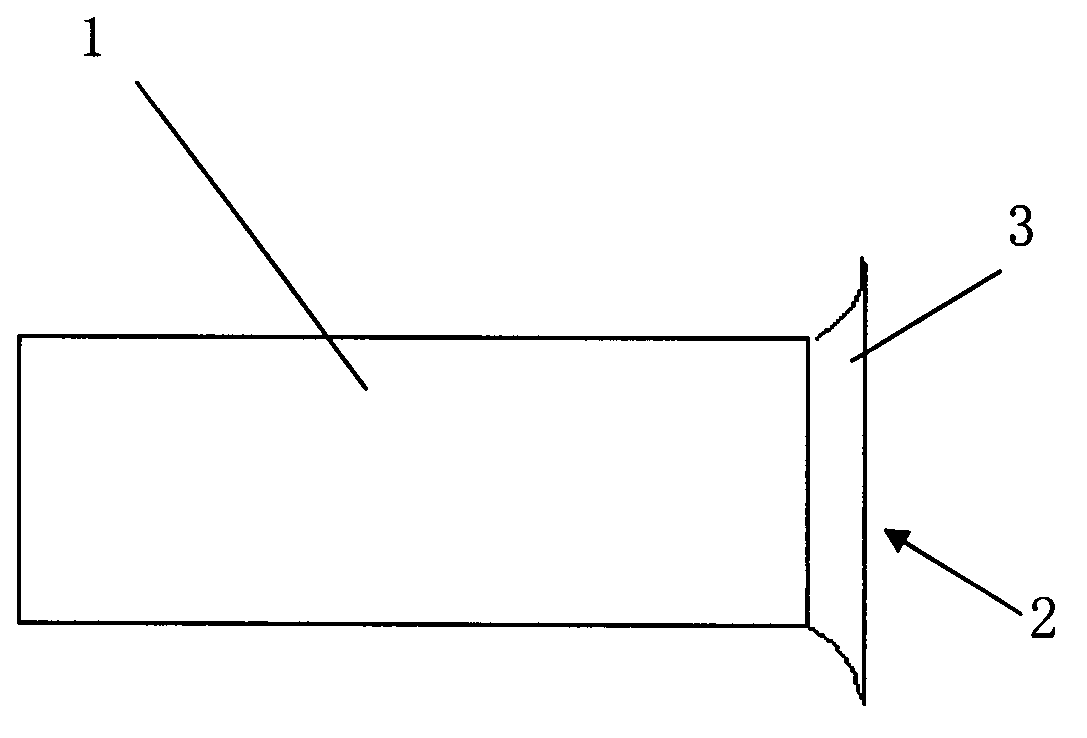

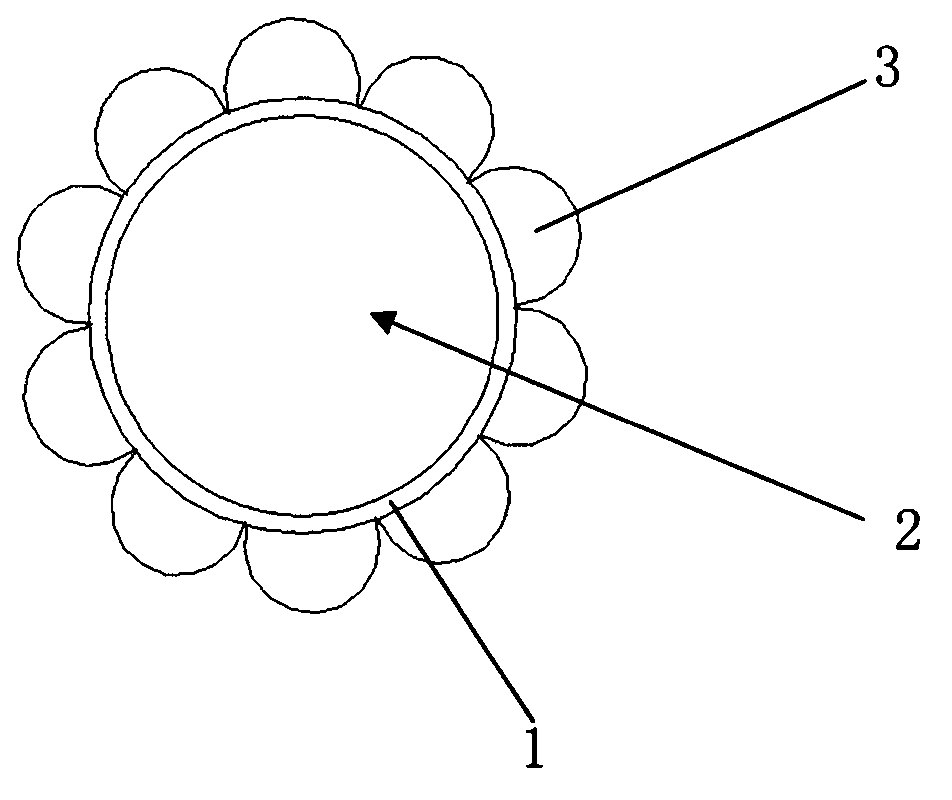

[0015] figure 1 It is a cross-sectional view of the middle steel sleeve of the air pressure sensor assembly structure of the present invention; figure 2 It is a schematic diagram of the position of the injection molding port of the steel sleeve in the assembly structure of the air pressure sensor of the present invention.

[0016] Such as figure 1 , figure 2 As shown, the assembly structure of the air pressure sensor of the present invention includes: a steel sleeve 1, which is shaped as a cylindrical structure with a closed top, and its end is provided with an outwardly extending injection molding port 2, and the cylinder wall at the edge of the injection molding port on the steel sleeve is outward Fold over to form hem 3. When the steel sleeve is inserted into the injection mold during injection molding, the flange formed at the injection port remains outside t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com