Surface inspection device

A surface inspection and to-be-inspected technology, applied in measuring devices, optics, instruments, etc., can solve the problems of slow detection speed, insufficient detection accuracy, residual, etc., to avoid inaccurate alarms, improve display effects, and control the thickness of the box. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

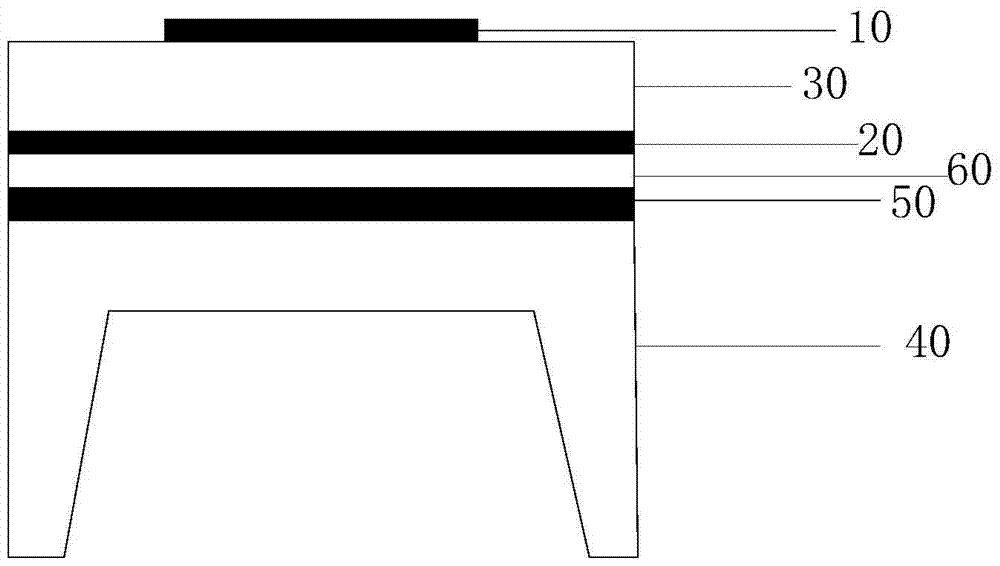

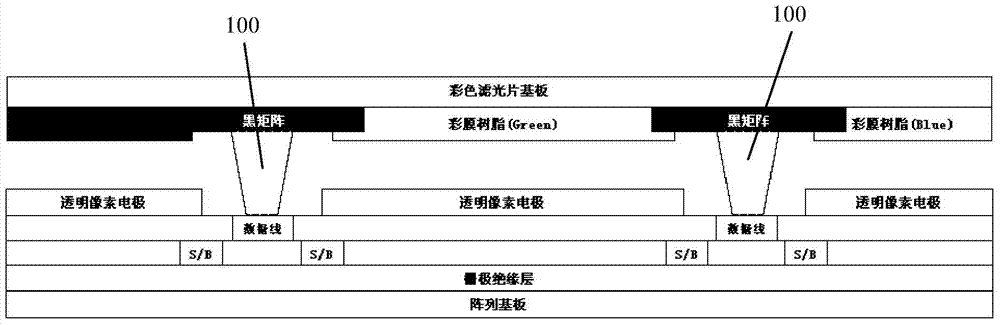

[0031] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

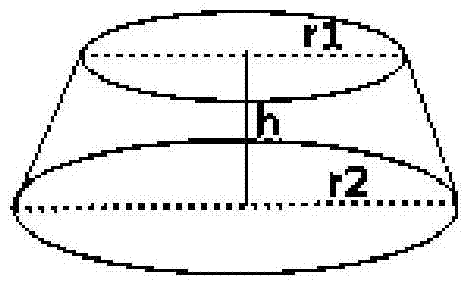

[0032] The surface detection device used in the display panel of the present invention uses the ultrasonic distance measuring principle of the piezoelectric ultrasonic transducer to measure the surface to be detected of the display panel, so that the detection result is more accurate.

[0033] The present invention specifically implements the surface detection device, including:

[0034] An ultrasonic transducer detection unit, configured to emit ultrasonic waves to the surface to be detected, and to obtain a feedback signal fed back after the ultrasonic waves reach the surface to be detected;

[0035] A processing unit, configured to calculate the position of the surface to be detected according to the feedback signal.

[0036] In the present invention...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com