Light source shaping method and structure used for projection

A technology of light source and laser light source, which is applied in the field of optoelectronics, can solve the problems of difficult to meet the design requirements, the reduction of beam spacing, and the influence of arrangement, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

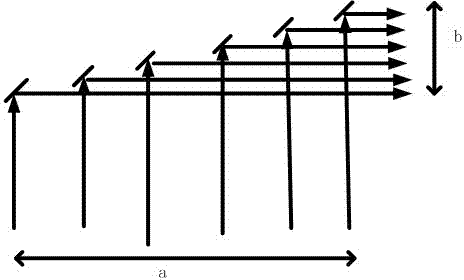

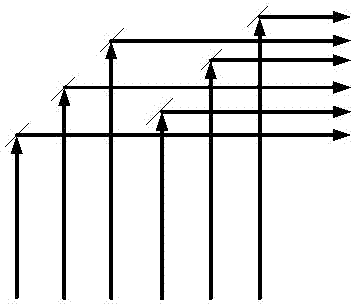

[0028]According to the layout of the laser array, the present invention divides the laser array into several large parts, each part is reflected by a group of mirrors placed on the same plane, and the mirrors of the same group are assembled on the same plane, but there are gaps between the mirrors. void. For example, every five columns of light beams form a group, and the reflectors of this group can be arranged on a large planar structure as follows. There is also a space between each reflector.

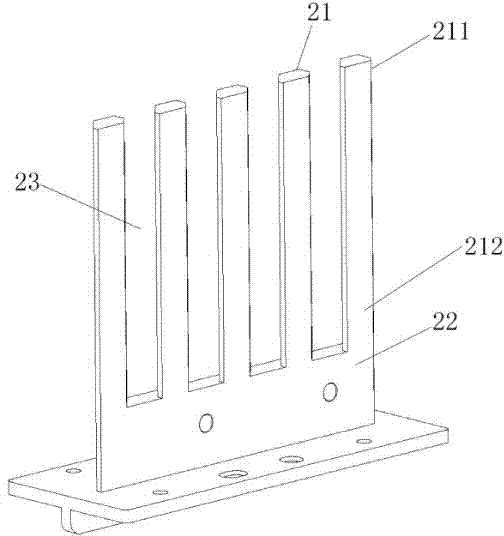

[0029] Such as figure 2 As shown, the reflector group is composed of five reflectors 21 and their fixing parts 22 , each set of reflectors has a predetermined interval between each reflector, and each reflector can be used to reflect multiple light beams. When part of the laser beams of the laser array are irregularly spaced or inconsistent with other parts, the space between the mirrors, that is, the gap 23 can be the same or can be set to different widths according to the arran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com