Powder box for electrophototgraphic imaging device and method for resetting detection gear thereof

An imaging device and an electrophotographic technology, which are applied to an electrical recording process using a charge pattern, equipment for an electrical recording process applying a charge pattern, and an electrical recording technique, can solve the problem of high requirements on reset switch sensitivity, and powder cartridge reset detection. The gear is troublesome, and it is impossible to accurately detect whether the powder box is installed in place, etc., so as to solve the problem of troublesome and easy reset of the detection gear.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046]The powder box A used in the present invention includes a developing element, a powder feeding element, a stirring element and carbon powder; Feed the powder-feeding element, the powder-feeding element is in contact with the developing element during the working process, and transports the carbon powder to the developing element, so that the charged carbon powder is attached to the developing element.

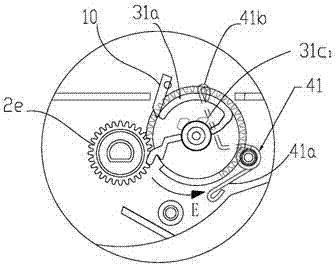

[0047] Such as figure 1 Shown is the three-dimensional schematic diagram of powder box A adopted in the present invention, figure 2 Shown is a schematic diagram of the front of the powder box A after removing the protective cover; figure 1 , 2 As shown, the powder box A also includes a powder box main body 1, a driving gear set 2, a detection gear 3 and a protective cover 5; toner is contained in the powder box main body 1; the driving gear set 2 and the detection gear 3 are arranged on the powder box main body 1 The protective cover 5 is assembled on the outside of t...

Embodiment 2

[0063] In this embodiment, the same structure or working process as in Embodiment 1 will not be described again here.

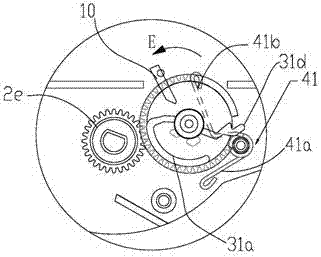

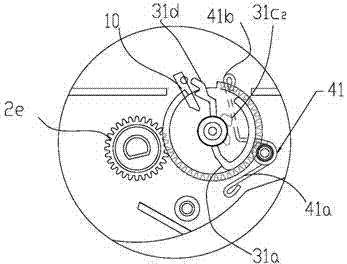

[0064] The difference from Example 1 is that, if Figure 7a As shown, the upper gear of the stirring element gear 22e is only partially provided with teeth on the circumference, and the upper gear meshes with the detection gear 3; Figure 7b As shown, the powder box is in the initial state (the state during production); when the stirring element gear 22e is in the state shown in the figure, the upper gear of the stirring element gear 22e is not meshed with the gear part on the detection gear 3, and the stirring element gear 22e is receiving After being rotated by the driving force from the electrophotographic imaging device, the upper gear meshes with the detection gear 3 and drives the detection gear 3 to rotate, so the detection gear 3 does not rotate synchronously with the driving gear set 2 during the working process of the powder box. Because the reset ...

Embodiment 3

[0067]In this embodiment, the same structure or working process as in Embodiment 2 will not be described again here.

[0068] Figure 8a Shown is a three-dimensional schematic diagram of the detection gear 33 used in this embodiment; the detection gear 33 is provided with a protruding part 33a, a notch 33b and an installation detection part 33d; the protruding part 33a and the installation detection part 33d are arranged on the same cylinder, and the outer surface The surface is in contact with the reset switch 10 during the operation of the powder container, so that the powder container A can be detected by the electrophotographic imaging device; the notch 33b on the protruding part 33a is provided on the cylindrical surface of the protruding part 33a.

[0069] When an unused powder container is installed on the electrophotographic imaging device, the detection gear 33 is in Figure 8b In the state shown, the protruding part 33a is in contact with the reset switch 10 so that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com