Nondestructive testing method of hot grid scanning thermal imaging

A technology of non-destructive testing and scanning heat, which is applied in the direction of material defect testing, etc., can solve the problem that the sampling frequency or signal sensitivity cannot effectively detect cracks in the vertical direction, and achieve the requirements of reducing the sampling frequency and signal sensitivity, low signal sensitivity, and high sampling efficiency. The effect of low frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

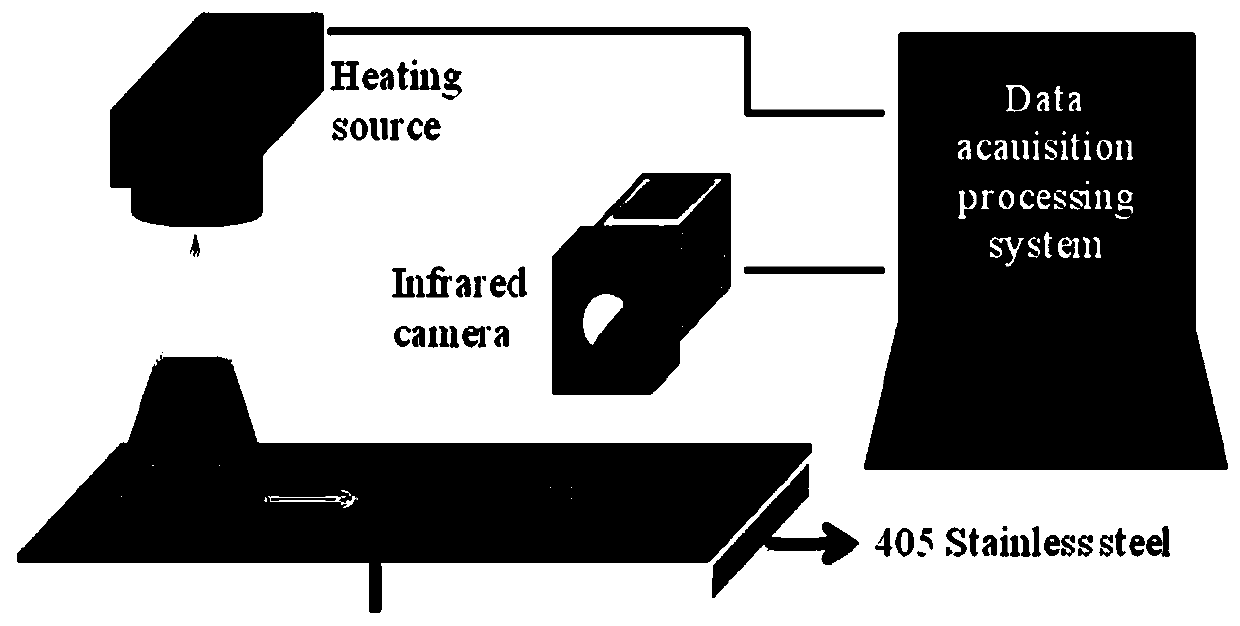

[0034] Comply with the above technical solutions, such as figure 1 As shown, this embodiment provides a thermal grid scanning thermal imaging non-destructive testing method, and the steps of this testing method are as follows:

[0035] Example 1 can detect vertical cracks in the ceramic thin film.

[0036]The detection frequency is 0.02Hz, the thermal grid wavelength is 40cm, the sample size is 40cm×4cm×1cm, and the surface is sprayed with yttria-stabilized zirconia (8wt.% YSZ) with APS to prepare a TBC coating with a thickness of 200μm.

[0037] In order to facilitate the understanding of the implementation of the invention, specific application descriptions are given below for the implementation of the invention.

[0038] (1) The moving grating image is generated by computer software, and the projector is used to project on the surface of the film. In order to enhance the thermal wave signal, it is better to use a traditional thermal light source projector instead of LED li...

Embodiment 2

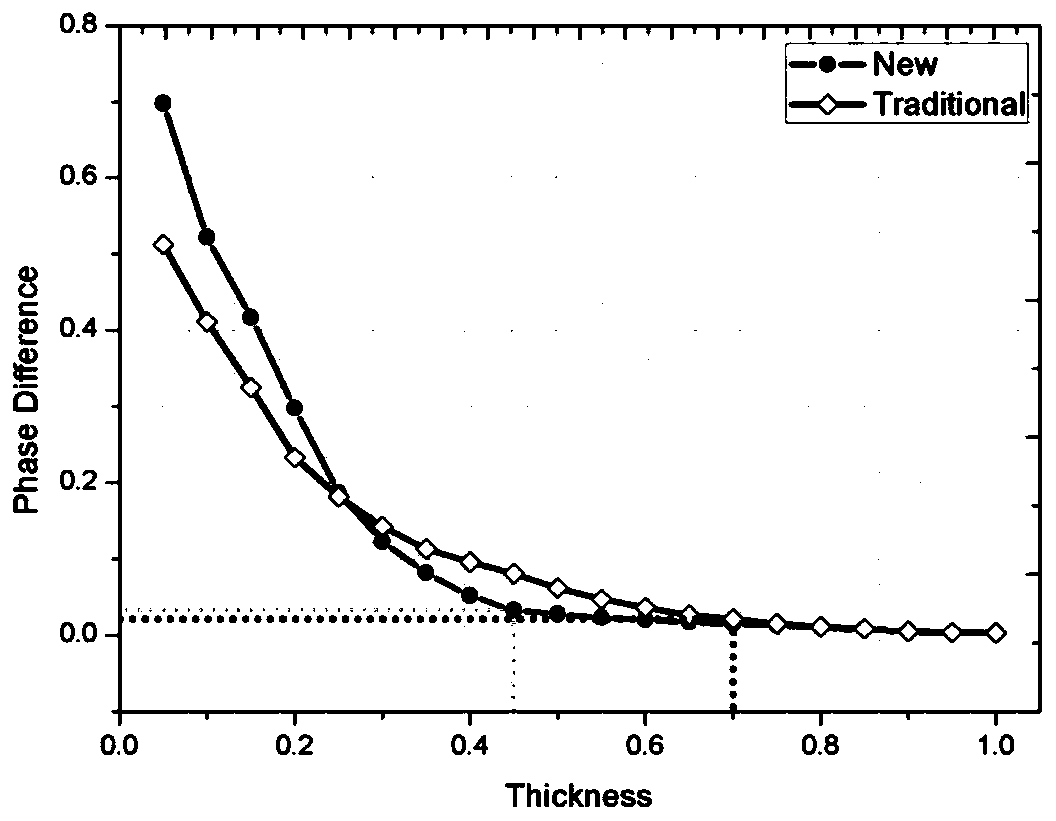

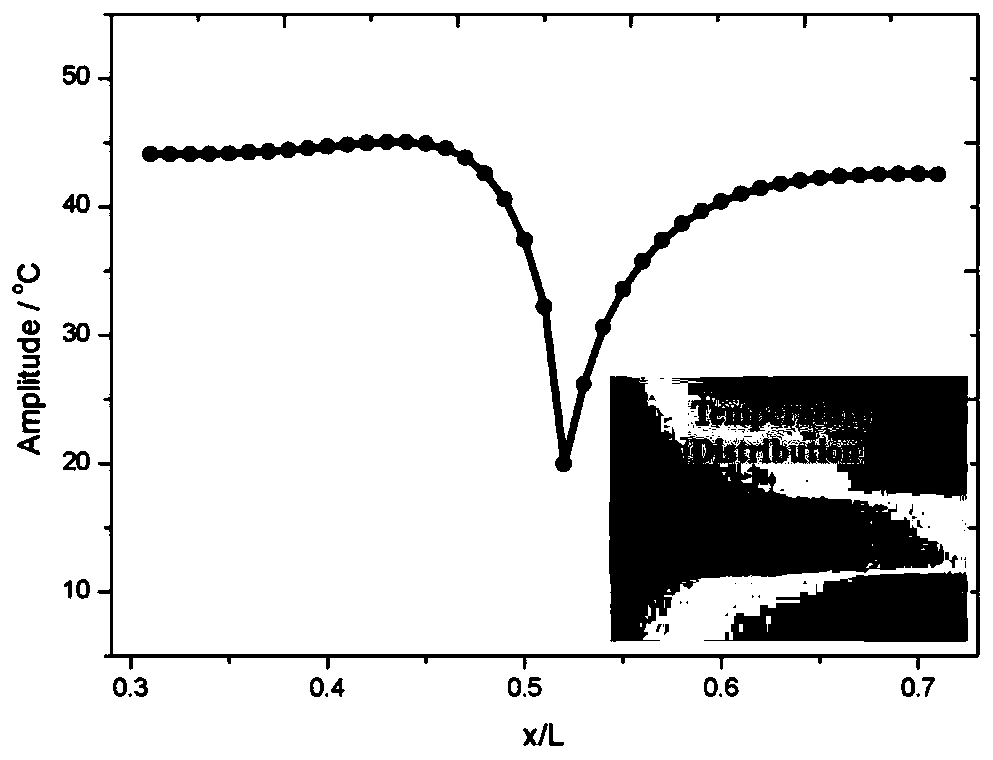

[0043] According to the above technical scheme, using MATLAB for numerical simulation analysis, this embodiment provides a thermal grid scanning thermal imaging non-destructive testing method, the steps of this testing method are as follows:

[0044] Example 2 can detect horizontal cracks in the ceramic thin film.

[0045] The detection frequency is 0.02Hz, the thermal grid wavelength is 40cm, the specimen size is 1cm×0.3cm×0.1cm, the material is 405 stainless steel, the horizontal crack length is 0.06cm, and the depth is 0.02cm.

[0046] In order to facilitate the understanding of the implementation of the invention, the implementation of this patent is given below with specific application instructions.

[0047] (1) The heat source loading form is 100*sin(0.02π*t+0.5*x), the initial temperature is 0, and the boundary conditions are adiabatic boundary conditions on all surfaces except the heating surface;

[0048] (2) Write the heat conduction calculation program by yourself...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com