Trigger device for monitoring dropping process of tiny droplets

A technology of triggering device and tiny droplets, applied in analytical materials, instruments, etc., can solve the problems of high price, inability to accurately monitor the falling process of tiny droplets, low utilization rate of experimental space, etc., so as to reduce the use area and widen the monitoring Scope, the effect of reducing the space occupied

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

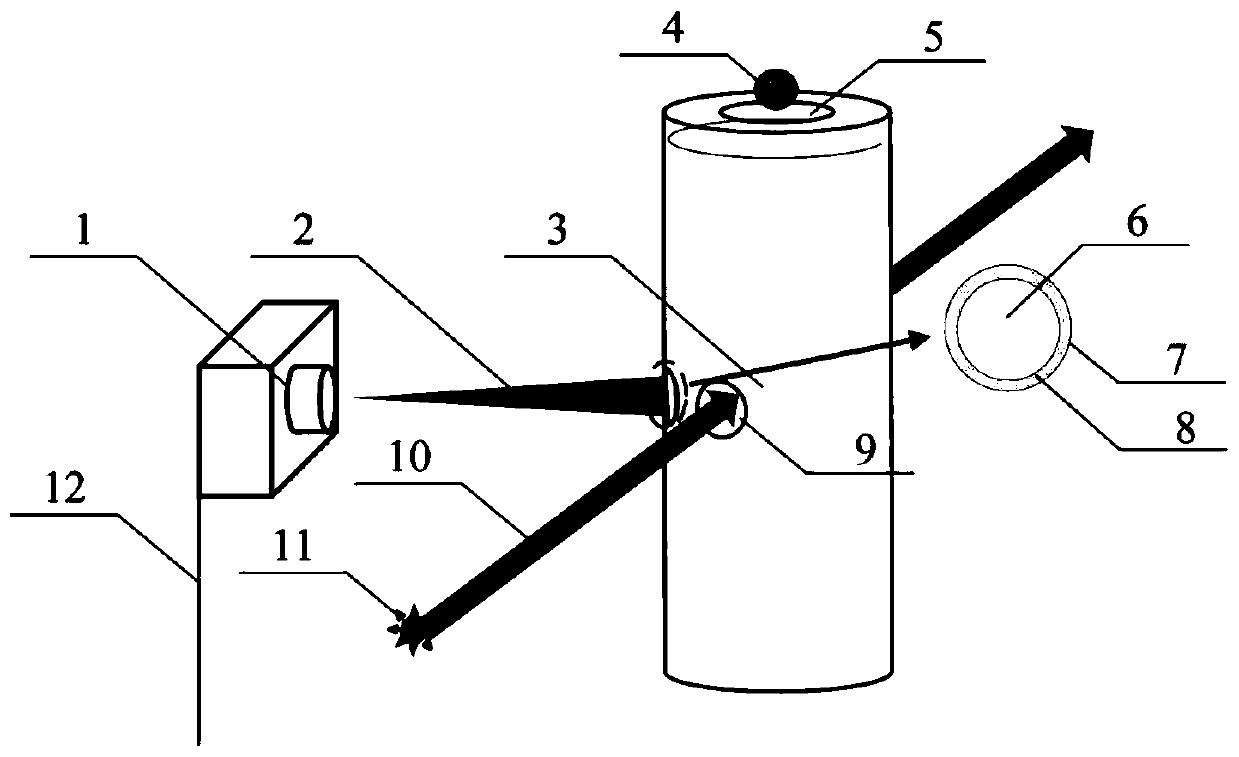

[0020] see figure 1 , the trigger device for monitoring the falling process of tiny droplets is characterized in that it consists of a photoelectric receiving device, a converging optical path, a connector, a droplet, a drop channel, a converging lens, a lens mounting cavity, an annular gasket, Optical path channel, cylindrical optical path, light source, trigger line; optical path generating system is mainly composed of light source, cylindrical optical path, optical path channel, mainly used to provide experimental parallel optical path; optical path receiving system is mainly composed of photoelectric receiving device, converging optical path, converging lens When the liquid drop passes through the cylindrical light path, the light reflected on the surface of the liquid drop is collected into the photoelectric receiving device through the converging lens, and the generated trigger signal is connected to the external device through the trigger line to control the progress of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com