Touch control panel and touch control display panel

A touch panel and touch sensing layer technology, which is applied in the fields of instruments, electrical digital data processing, and data processing input/output processes, etc. Problems such as peeling occur to achieve the effect of good yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

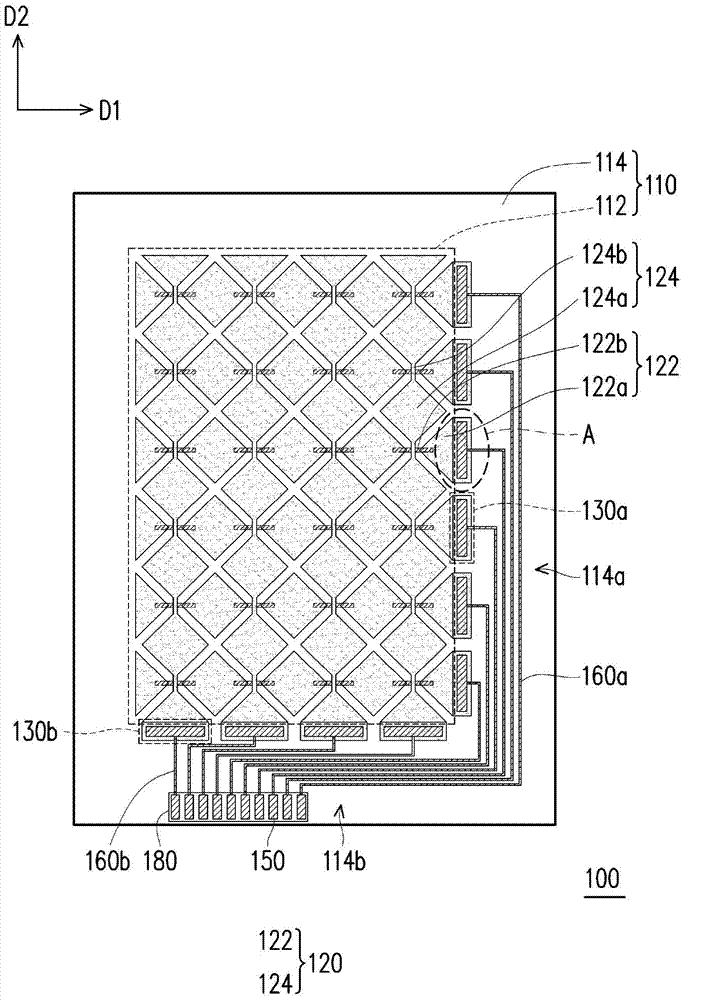

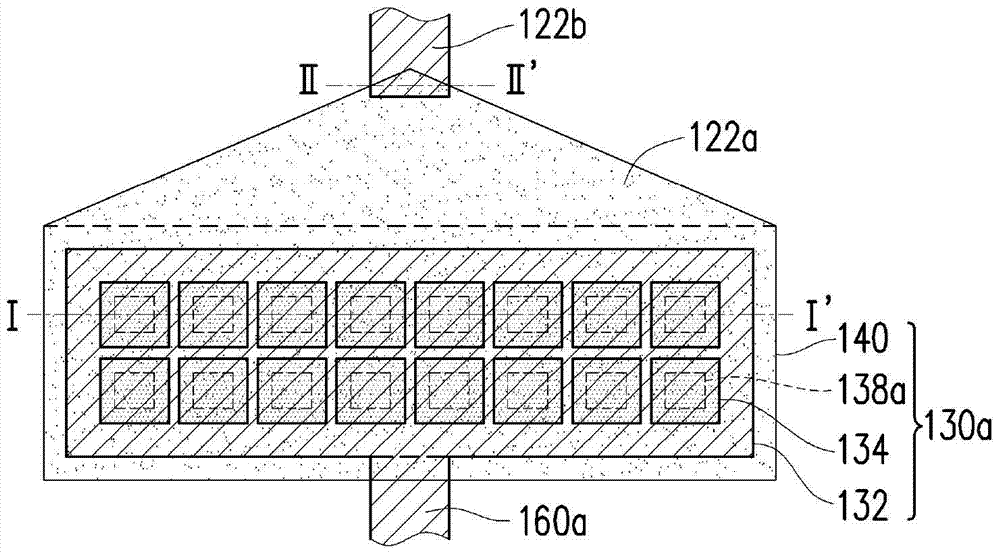

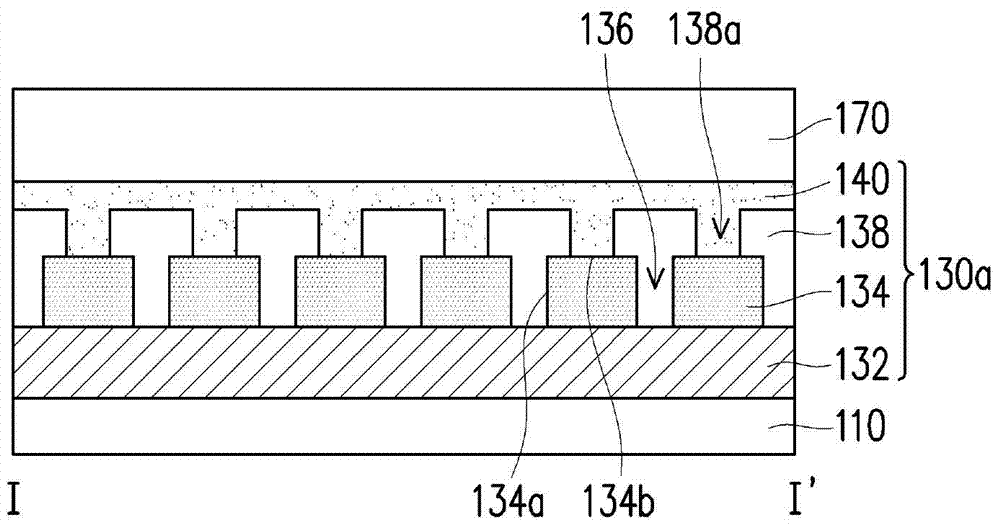

[0067] Figure 1A is a schematic top view of a touch panel according to an embodiment of the present invention, Figure 1B for Figure 1A An enlarged schematic view of region A of , and Figure 1C and Figure 1D respectively along Figure 1B The cross-sectional schematic diagram of line I-I' and line II-II'. Please also refer to Figure 1A to Figure 1DThe touch panel 100 includes a substrate 110 , a touch sensing layer 120 , transfer structures 130 a , 130 b , contact pads 150 , and connecting wires 160 a , 160 b. The substrate 110 has a sensing area 112 and a peripheral area 114 . In this embodiment, the substrate 110 is a transparent substrate, such as a glass substrate, a plastic substrate, a flexible substrate or other substrates. The peripheral area 114 is, for example, surrounding the sensing area 112 , and the peripheral area 114 is, for example, overlapping with the black matrix pre-shading area. That is to say, in the touch panel 100 , the sensing area 112 is, f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com