A Ceramic Pillar Grid Array Used in Experiments

A technology of ceramic column grid array and ceramic substrate, which is applied in the direction of metal pattern materials, electrical connection printed components, printed circuit components, etc., and can solve the problems of high price and poor availability of CCGA devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

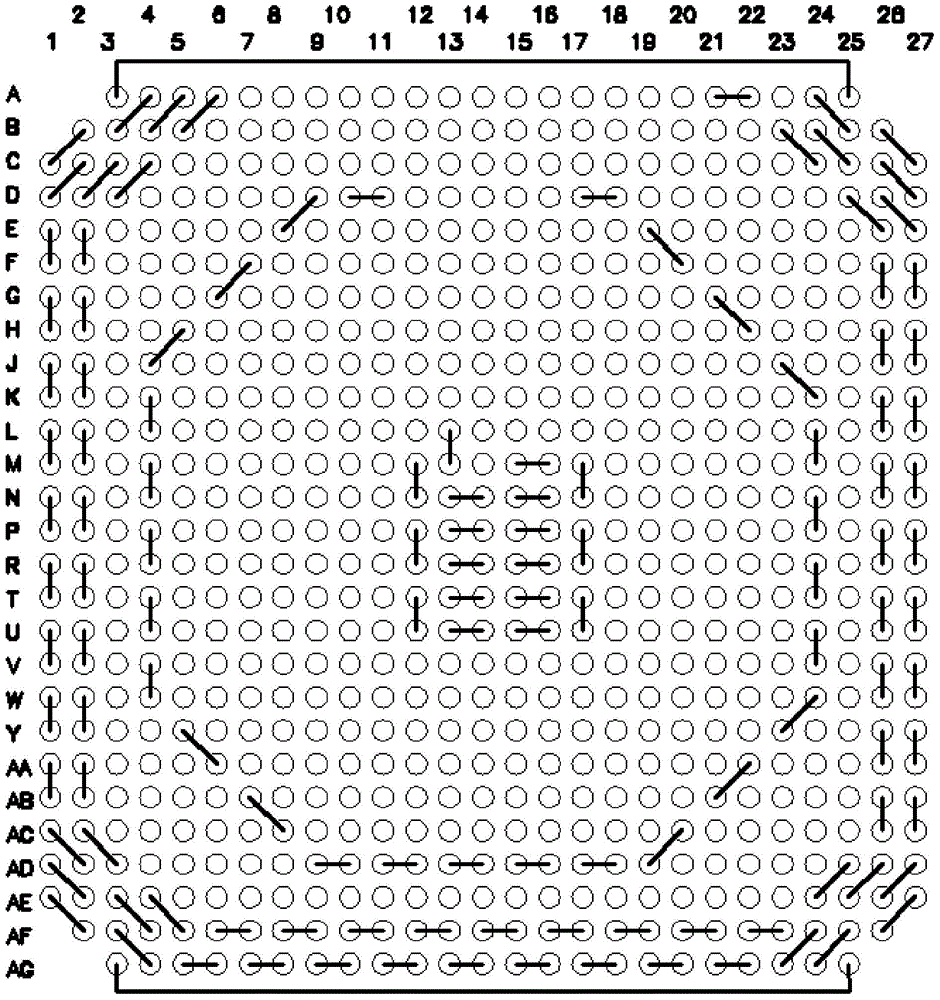

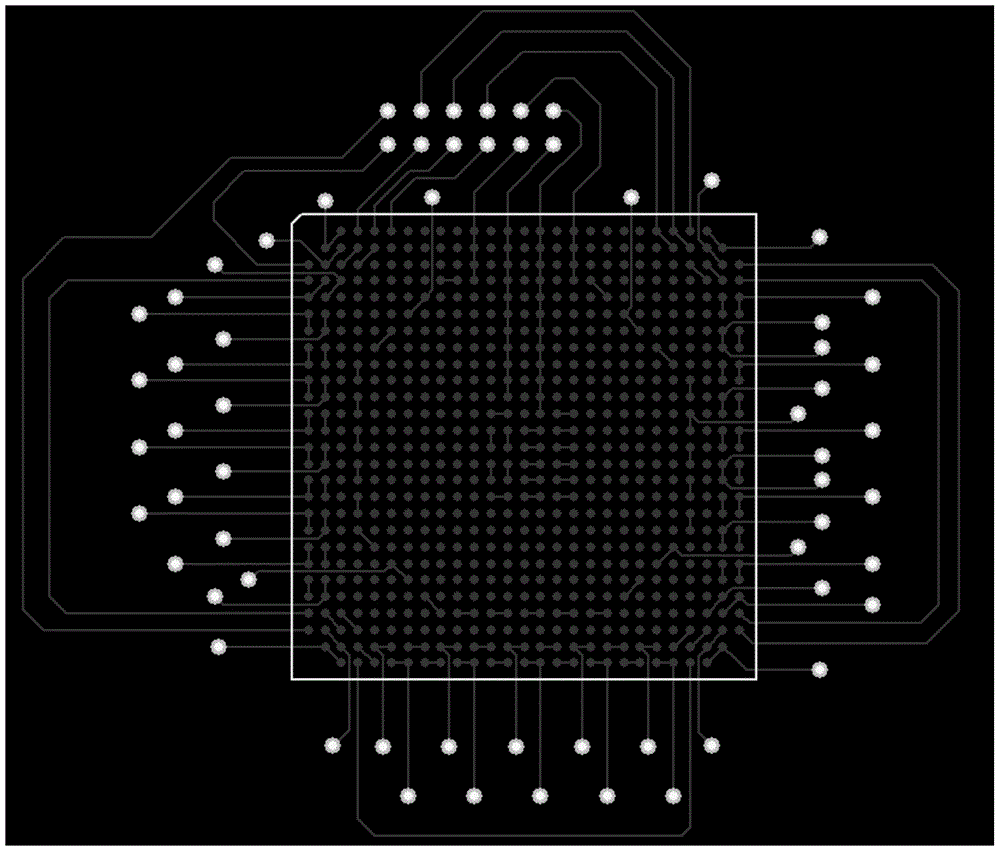

[0024] A ceramic column grid array for testing, the ceramic column grid array includes a ceramic substrate, welding columns and a printed board;

[0025] The ceramic substrate material is Al 2 o 3 , co-fired at a temperature of 1600 ° C to obtain a ceramic substrate, the bottom of the ceramic substrate is screen-printed with pads with a diameter of 0.8 mm and a daisy chain circuit; the pad spacing is 1.27 mm;

[0026] The diameter of the welding column is 0.5mm, and the material is Pb90Sn10. It is welded with the corresponding pad of the ceramic substrate by reflow soldering, and a total of 717 pieces are required; the welding column is cut into short columns with a length of 2.2mm through the solder wire;

[0027] There are screen-printed pads and daisy chain circuits on the printed board; the pad diameter is 0.8mm, and the pad spacing is 1.27mm;

[0028] There is a daisy chain circuit corresponding to the ceramic substrate on the printed board, and the daisy chain circuit ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com