Manufacturing method for forming conductor circuit on non-conductive substrate

A conductor circuit and manufacturing method technology, applied in the direction of removing conductive materials by chemical/electrolytic methods, can solve the problems of high material control and process technology integration capabilities, high technical thresholds, etc., to shorten the manufacturing process and development cycle, The effect of reducing cost and improving bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to further have a clearer and more detailed understanding of the purpose, technical solutions and advantages of the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

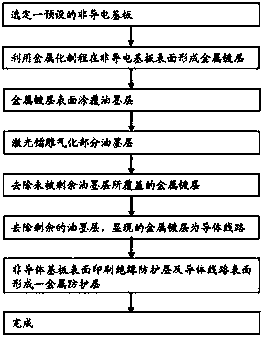

[0026] Please refer to Figure 1 to Figure 8 As shown, the manufacturing method for forming the conductor line 40 on the non-conductive substrate 10 of the present invention includes the following steps:

[0027] a. A non-conductive substrate 10 is selected, and the non-conductive substrate 10 is made of one of alumina, aluminum nitride and silicon carbide ceramic materials. In other embodiments, the non-conductive substrate 10 is one of thermally conductive plastic, glass or carbon fiber, and the present invention has no special requirements for the material of the non-conductive substrate 10 .

[0028] b. Through the metallization process on the surface of the above-mentioned non-conductive substra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com