Snow-proof external sun-shading system applied to Venlo type multi-span glass greenhouse

A glass greenhouse and external sunshade technology, applied in the field of external sunshade systems, can solve problems such as greenhouse damage, achieve strong wind resistance and save costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

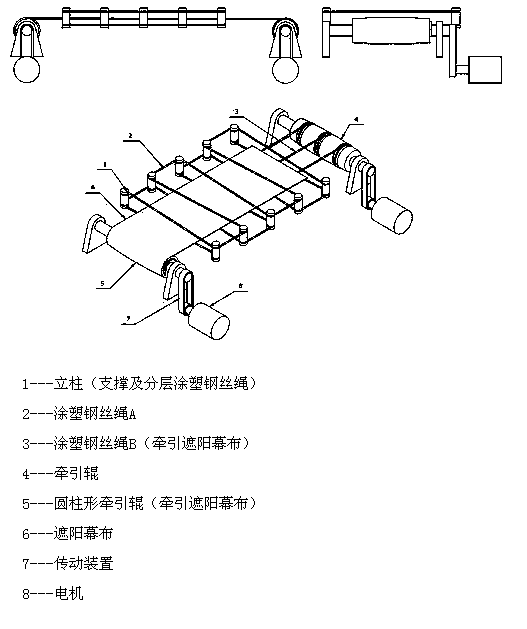

[0013] Such as figure 1 As shown, the external sunshade system with snow protection function is composed of column 1, plastic-coated steel wire rope A2, plastic-coated steel wire rope B3, traction roller 4, cylindrical traction roller 5, sunshade curtain 6, transmission device 7 and motor 8, in which the column 1 is used for supporting and layering the plastic-coated steel wire rope A2, the plastic-coated steel wire rope A2 plays the role of support and windproof, the plastic-coated steel wire rope B3 and the cylindrical traction roller 5 are used for pulling the sunshade curtain 6, and the traction roller 4 is used for retracting and unwinding the plastic-coated steel wire rope B3, According to the material of the sunshade curtain 6, the horizontal spacing of the steel wire ropes is set to 30cm~100cm, and they are fixed on the metal structure grid on the greenhouse roof. The metal structure grid is fixed on the gutter and is higher than the roof glass. The movement of the suns...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Horizontal spacing | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com