Preparation method of hydrophobic chemical group modified waterproof glass

A chemical group and glass technology, applied in the field of engineering materials, can solve the problems of affecting the use effect, high price, loss of super waterproof performance, etc., and achieve the effect of wide application space, wide application prospect and good application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] 2. Preparation of self-assembled molecular layer

[0023] ① Fully clean the glass with acetone, absolute ethanol, and deionized water in sequence. Each liquid is washed three times in an ultrasonic cleaner and dried to obtain a blank clean glass;

[0024] ② Immerse the dried blank clean glass in the pre-prepared Pirahan solution, treat it in a water bath at 80°C for 1 h, take out the glass, wash it thoroughly with deionized water, and dry it with high-purity nitrogen to obtain the OH surface glass;

[0025] ③Immerse the resulting OH surface slides in CH one by one 3 Monomolecular layer surface reaction solution, reacted in a water bath at 55°C for 1 h, washed with absolute ethanol and deionized water in turn, dried with high-purity nitrogen, and obtained CH 3 surface slides;

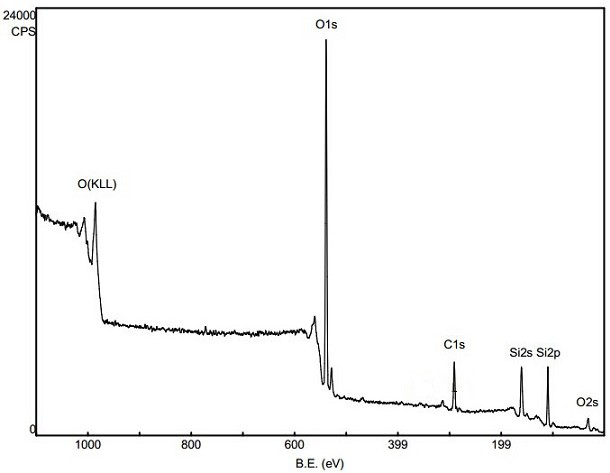

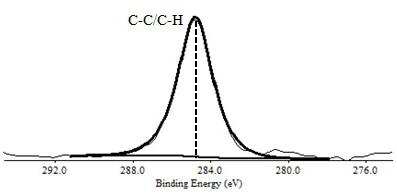

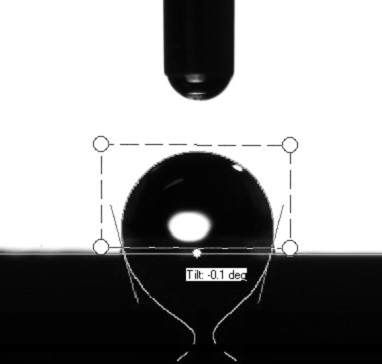

[0026] as attached figure 1 , 2 Shown, for CH 3 The full-spectrum and C-spectrum XPS detection patterns of the surface show that the surface of the glass mirror surface has successfully incor...

Embodiment 1

[0029] A method for preparing waterproof glass modified by hydrophobic chemical groups is characterized in that it comprises the following steps:

[0030] (1) Configuration of Pirahan solution: measure 700 ml 30% H 2 o 2 Pour into a clean beaker, place the beaker in an ice bath environment, and measure 300 ml 98% H 2 SO 4 , slowly add H 2 o 2 solution, and continuously stirred slowly with a glass rod.

[0031] (2) CH 3 Configuration of the reaction solution on the surface of the monomolecular layer: Take 5 ml of dimethyloctadecylchlorosilane and dissolve it in 500 ml of n-hexane solution to prepare a reaction solution with a volume ratio of 5%.

[0032] (3) Preparation of self-assembled molecular layer:

[0033] 1) Fully clean the glass with acetone, absolute ethanol, and deionized water in sequence. Each liquid is cleaned and dried in an ultrasonic cleaner to obtain a blank clean glass;

[0034] 2) Immerse the dried blank clean glass in the pre-prepared Pirahan soluti...

Embodiment 2

[0037] A method for preparing waterproof glass modified by hydrophobic chemical groups is characterized in that it comprises the following steps:

[0038] (1) Configuration of Pirahan solution: measure 700 ml 30% H 2 o 2 Pour into a clean beaker, place the beaker in an ice bath environment, and measure 300 ml 98% H 2 SO 4 , slowly add H 2 o 2 solution, and continuously stirred slowly with a glass rod.

[0039] (2) CH 3 Configuration of the reaction solution on the surface of the monomolecular layer: Take 5 ml of dimethyloctadecylchlorosilane and dissolve it in 500 ml of n-hexane solution to prepare a reaction solution with a volume ratio of 5%.

[0040] (3) Preparation of self-assembled molecular layer:

[0041] 1) Fully clean the glass with acetone, absolute ethanol, and deionized water in sequence. Each liquid is cleaned and dried in an ultrasonic cleaner to obtain a blank clean glass;

[0042] 2) Immerse the dried blank clean glass in the pre-prepared Pirahan soluti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com