Preparation method of octopus balls

A production method and octopus technology, which are applied in food preparation, food forming, food science and other directions, can solve problems such as unreported, and achieve the effect of rich aroma

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Embodiment 1, a kind of preparation method of octopus ball, carries out following steps successively:

[0045] The following parts are parts by weight;

[0046] 1) Slurry chopping and mixing:

[0047] First add 5g of compound phosphate (obtained by mixing the mass ratio of sodium tripolyphosphate: sodium pyrophosphate = 3:1) into 1kg of semi-thawed frozen surimi (grade A miscellaneous surimi) and mix for 3 minutes, then add 20g of edible salt was chopped and mixed for 5 minutes to obtain a viscous, non-grainy surimi slurry;

[0048] Add 50g of raw potato starch, 50g of acetylated distarch phosphate, 50g of soybean protein isolate, 20g of white sugar, 10g of monosodium glutamate and 35g of spices into the surimi slurry to obtain a composite slurry; High-speed chopping and mixing, adding ice water during the chopping process to adjust the moisture content of the composite slurry to 75%, to obtain a uniform composite slurry;

[0049] 2), material mixing:

[0050] The f...

Embodiment 2

[0066] Embodiment 2, make the following changes with respect to embodiment 1:

[0067] Change the weight of fresh octopus foot particles into 100g from 200g; all the other contents are equal to embodiment 1.

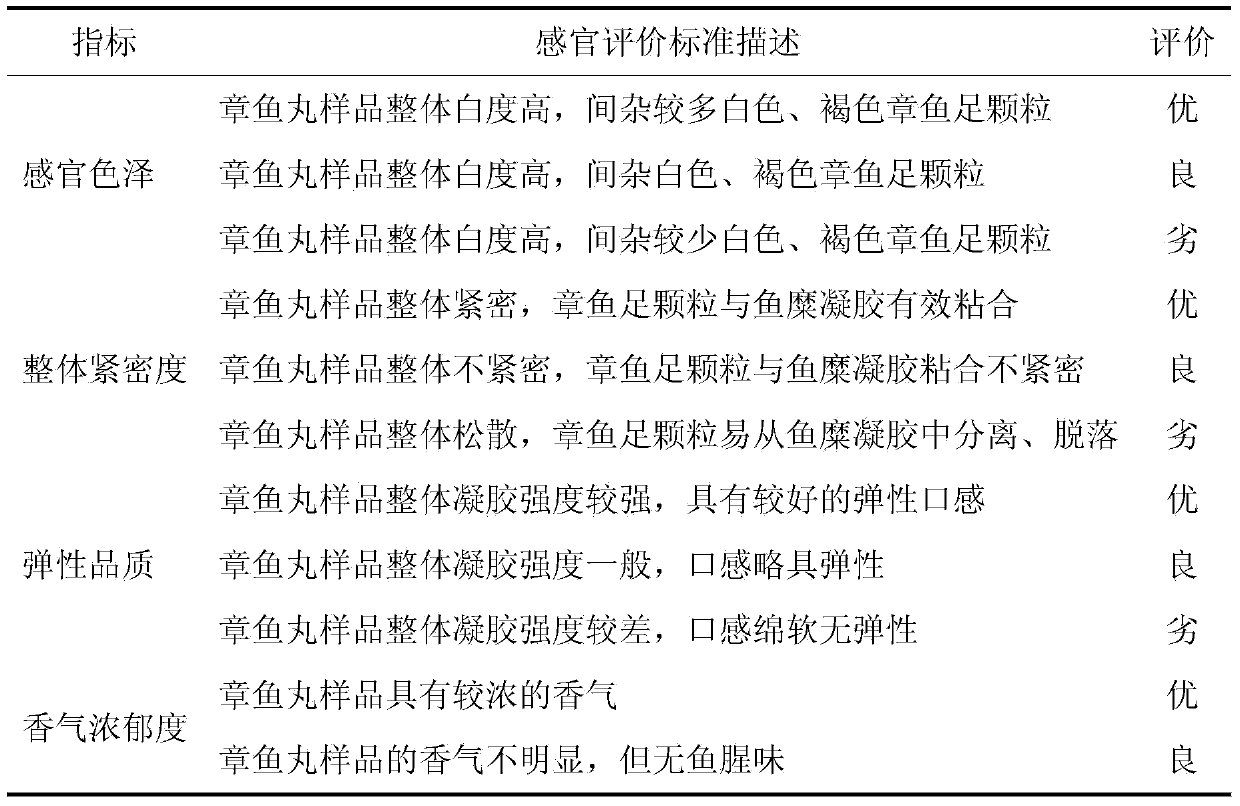

[0068] After testing, in terms of the overall sensory color of the octopus balls, the overall whiteness of the octopus ball samples in this embodiment is significantly higher than that of the sample in Example 1, but the interspersed white and brown octopus foot particles are slightly less than the sample in Example 1, and it is rated as " good". At the same time, the reduction in the addition of octopus foot particles increased the gel strength of the overall texture of octopus balls, and the overall compactness index and elastic quality index were evaluated as "excellent". But the richness of aroma of the sample of this embodiment is significantly lower than the sample of Example 1, and the index of richness of aroma is evaluated as "good", which reduces the product c...

Embodiment 3

[0069] Embodiment 3, make the following changes with respect to embodiment 1:

[0070] The frozen surimi was changed from grade A miscellaneous surimi to AAA grade miscellaneous surimi, and the remaining contents were identical to those in Example 1.

[0071] After testing, the sensory color, aroma intensity, and hygienic standards of the octopus balls are all similar to those of Example 1. The sensory color index is "excellent", the overall compactness index is "excellent", the elasticity quality index is "excellent", The index of aroma intensity is "excellent". The high-grade frozen surimi greatly improves the gel strength of the overall texture of the octopus balls. It is known from specific measurements that the gel strength value of octopus balls has increased from 200 to 280g×cm in Example 1 to 390 to 450g×cm in Example 3, and the combination of octopus foot particles and surimi gel in the sample of Example 3 It is more compact and is in a highly dense state, which is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com