Laser vision cooling device

A cooling device and laser technology, used in auxiliary devices, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve problems such as camera failure, camera collision, camera damage, etc., to achieve good monitoring effect, ensure normal operation, The effect of improving cooling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

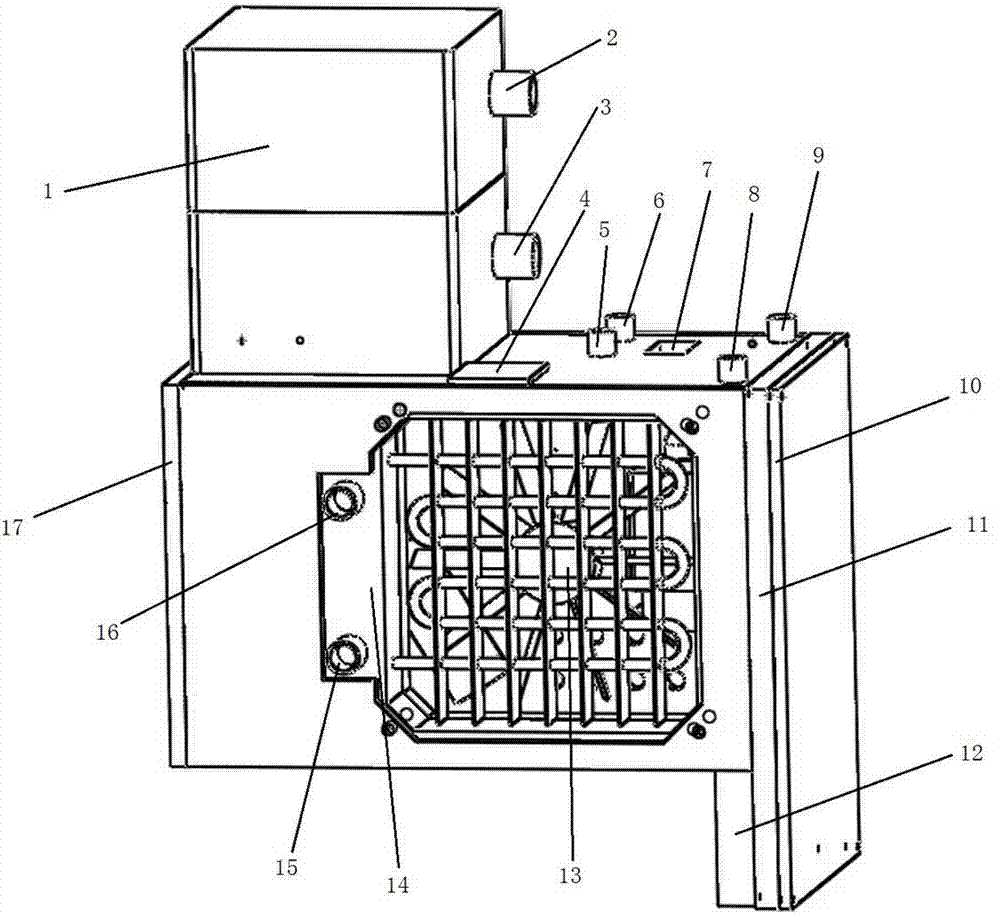

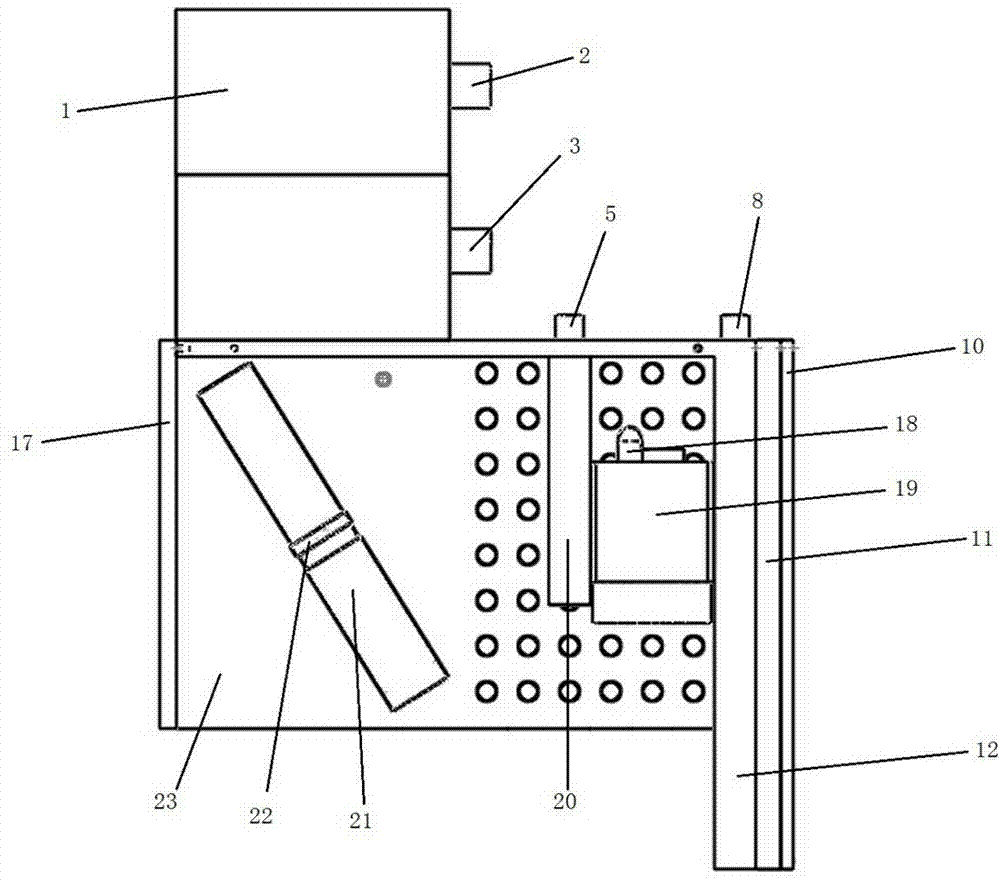

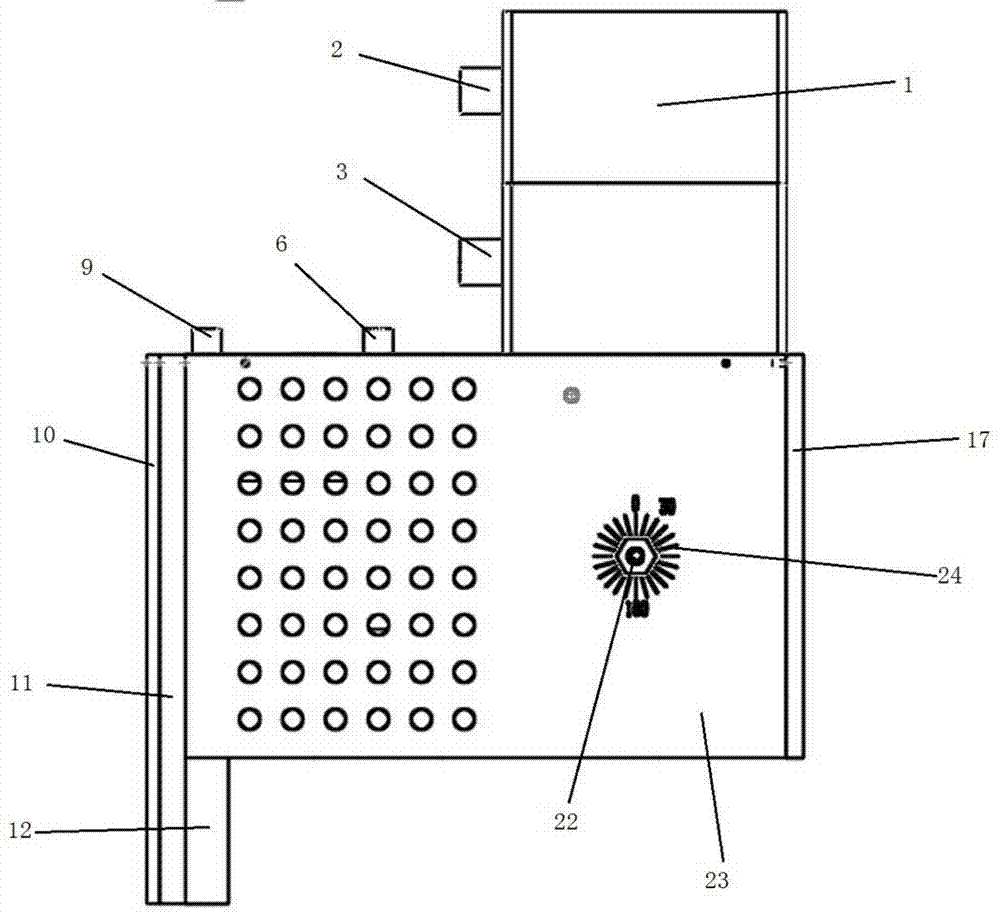

[0025] Such as figure 1 As shown, the laser vision cooling device includes a rectangular housing 23, a left baffle 17 located on the left side of the housing 23 and a right baffle 10 located on the right side of the housing 23, the left baffle 17 and the right baffle 10 play a fixed role. Such as figure 2 As shown, the housing 23 is also provided with a laser fixture 22 and a camera 19 , and the laser fixture 22 is provided with a laser 21 .

[0026] Such as figure 1 As shown, the top of the housing 23 is provided with a water pump 1 having a water inlet one 2 and a water outlet one 3 thereon, and the front part of the housing 23 is provided with a water cooling row 14 having a water inlet two 16 and a water outlet two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com