Surgical tray cover bag and preparation method for same

A tray and surgery technology, which is applied in the field of surgical tray bagging and its preparation, can solve the problems of low production capacity, high cost, and low production capacity of surgical tray bagging, so as to alleviate the shortage of human resources, low cost, and good thickness uniformity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

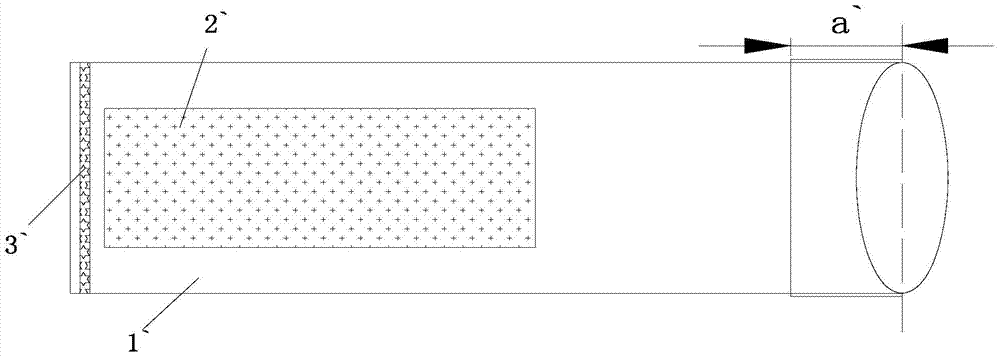

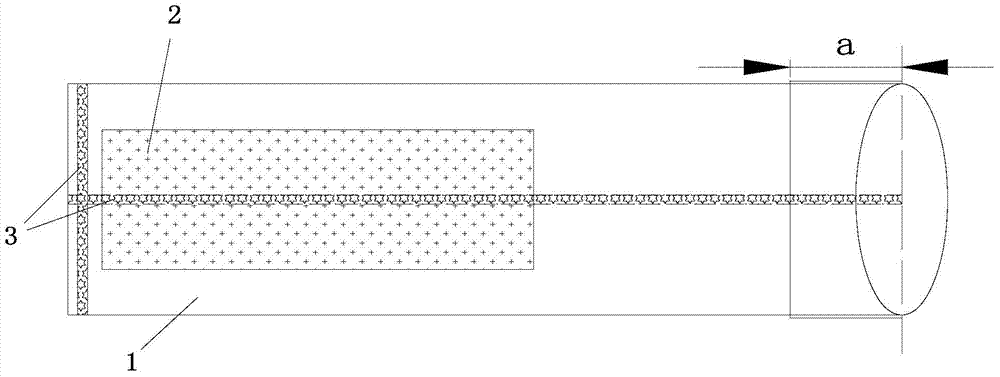

[0058] On-line laminating process to produce surgical tray bagging (heat bonding method, free of hot melt adhesive, hydrosol, reactive glue or double-sided tape, etc.)

[0059] The casting and bonding process steps of this embodiment are as follows:

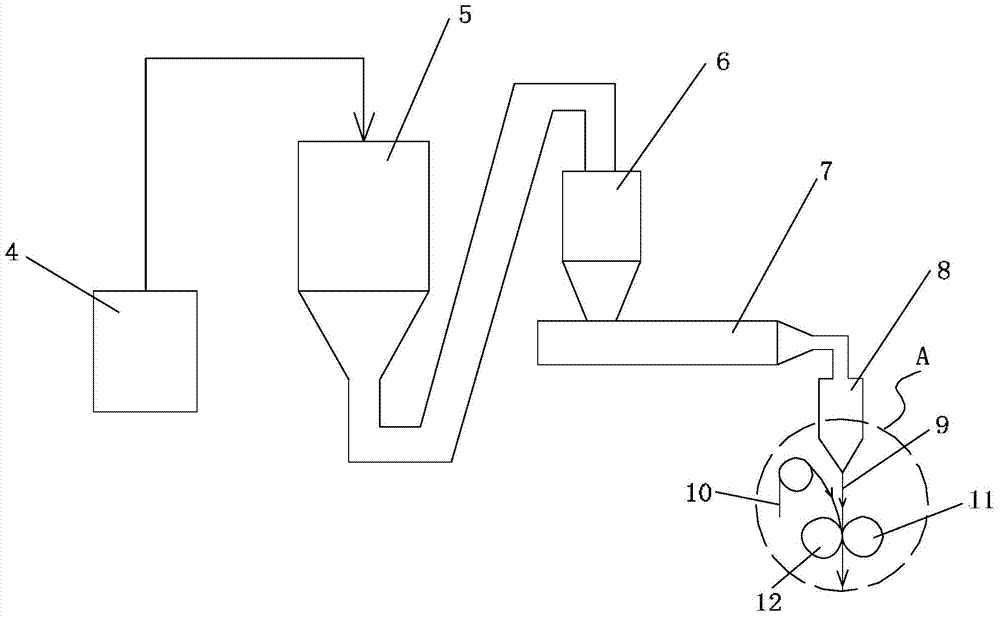

[0060] (1) According to the formula of the tubular film layer 1, weigh the raw materials from the weighing device 4, then add them to the high-speed mixer 5 and mix them evenly, then send them from the hopper 6 to the casting machine 7 for heating and melting, and then from the casting machine The T-shaped die head 8 of 7 flows out and casts into a flat film 9. When the flat film 9 is still in a molten state, the absorbent layer roll material 10 is conveyed to the flat film 9 by a conveyor belt to be bonded, and then pressed, cooled, solidified, Molding is made into a flat film with an absorbent layer; in this step, the device for lamination is at least: a steel rod 11 and a rubber roller 12, and the flat film 9 and the absorbent...

Embodiment 2

[0065] Production of surgical tray sleeves by in-line bonding of absorbent layers (gluing with hot-melt, hydrosol or reactive glue, etc.)

[0066] The casting and bonding process steps of this embodiment are as follows:

[0067] (1) According to the formula of the tubular film layer 1, weigh the raw materials from the weighing device 4, then add them to the high-speed mixer 5 and mix them evenly, then send them from the hopper 6 to the casting machine 7 for heating and melting, and then from the casting machine The T-shaped die head 8 of 7 flows out and casts into flat film 9. After the flat film 9 is cooled and solidified, glue gun 18 is used to spray glue 19 on-line, and at the same time, the cut absorbing layer 2 is transported to the appropriate position for spraying glue 19 with a conveyor belt, and then the flat film 9 and the absorbing layer 2 are bonded together; The length, width and position of the absorbing layer 2 can be adjusted according to product requirements....

Embodiment 3

[0071] Production of surgical tray bagging by laminating the absorbent layer offline (by manual lamination)

[0072] The casting and bonding process steps of this embodiment are as follows:

[0073] (1) According to the formula of the tubular film layer 1, weigh the raw materials from the weighing device 4, then add them to the high-speed mixer 5 and mix them evenly, then send them from the hopper 6 to the casting machine 7 for heating and melting, and then from the casting machine The T-shaped die head 8 of 7 flows out and casts into flat film 9. After the flat film 9 is cooled and solidified, the films on both sides are folded by a triangular folding machine 13 or other folding devices (such as Figure 9 shown), and then enter the heat-sealing machine 14 for heat-sealing. The overlapping size of the heat-sealing edge can be adjusted between 0.1-5cm according to product requirements, preferably 0.5-1cm. The heat-sealed film material is in the form of a tube and rolled up, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com