Thermochromic smart window and preparation method thereof

A thermochromic and smart window technology, applied in chemical instruments and methods, layered products, metal layered products, etc., can solve the problem of high phase transition temperature of smart windows, and achieve the effect of broadening the scope of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

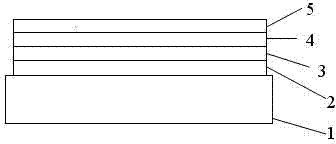

[0030] See attached figure 1 , the present embodiment is an all-thin-film structure, and its film layers from bottom to top are: substrate 1, electric heating layer 2, buffer layer 3, thermochromic layer 4, and protective layer 5. The preparation method of this embodiment is as follows:

[0031] See attached figure 1 ,

[0032] (1) Preparation of the substrate: cut a common flat glass substrate into a 10cm*10cm square, ultrasonically wash it in acetone for 10 minutes, and then ultrasonically wash it in alcohol for 20 minutes.

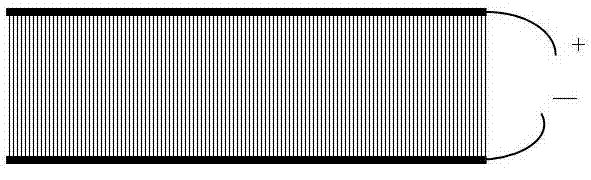

[0033] (2) Preparation of the electric heating layer: Prepare the electric heating layer on the cleaned substrate, print it with ITO transparent conductive glue, design a simple circuit diagram that can form a circuit on the screen in advance, bake it after printing, and put the prepared electric heating layer The substrate is fixed on the sample holder of the magnetron sputtering instrument. See attached image 3 or attached Figure 4 , horizonta...

Embodiment 2

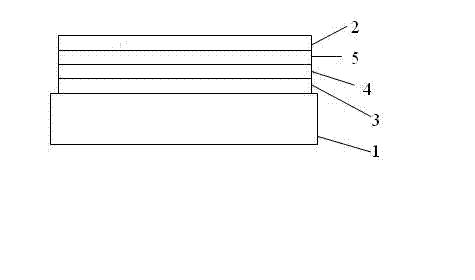

[0061] See attached figure 2 In this embodiment, the film layer structure from bottom to top is: substrate 1 , buffer layer 3 , thermochromic layer 4 , protective layer 5 , and electric heating layer 2 . The preparation method of this embodiment is as follows:

[0062] See attached figure 2 ,

[0063] (1) Preparation of the substrate: Cut a common flat glass substrate into a 10cm*10cm square, ultrasonically wash it in acetone for 10 minutes, and then ultrasonically wash it in alcohol for 20 minutes.

[0064] (2) Preparation of the buffer layer: use intermediate frequency or DC sputtering, select the target material Ti, and the reaction gas is Ar and O 2 , the substrate is heated to grow the buffer layer.

[0065] The specific parameters are as follows:

[0066] Substrate temperature: 500°C.

[0067] Gas ratio: Ar: O 2 =7:1;

[0068] Working pressure: 1.0Pa;

[0069] Sputtering power: 150W;

[0070] Sputtering time: 20min;

[0071] Film thickness: 80nm.

[0072] (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Film thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com