Cyclone air flotation apparatus

A swirl air flotation and overflow technology, which is applied in the direction of flotation water/sewage treatment, etc., can solve the problems of high power consumption, difficulty in reaching the effluent index of physical and chemical pretreatment, and low technical content, and achieve the effect of increasing the water inlet pressure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

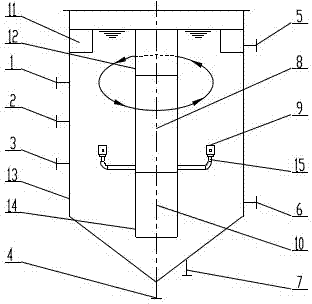

[0013] A swirling air flotation device, comprising a vertical cylinder 13, one side of the cylinder 13 is provided with a water inlet 1, an air inlet 2, and a return opening 3, and the bottom end of the cylinder 13 is provided with a slag discharge port 4 and Vent 7, the other side of the cylinder 13 is provided with a water outlet 6 near the bottom, and an overflow port 5 is provided near the top. The center of the cylinder 13 is provided with a central cylinder, which is divided into upper, middle and lower chambers. The upper chamber 12 is a slag collection tank, and the pipes in the upper chamber 12 are connected to the slag outlet 4. The middle chamber 8 has a built-in microbubble generator, and several branch pipes 15 are distributed around the middle chamber 8. The branch pipes The end of 15 is provided with an injector 9, and the lower chamber 10 is a sump. An overflow tank 11 is provided at the overflow port 5 . The pipeline of the water inlet 1 is arranged tangentia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com