Tunnel type slag-hole-adjustable continuous fuming furnace

A tunnel-type fuming furnace technology, applied in furnaces, furnace types, lighting and heating equipment, etc., can solve the problems of discontinuous steam peaks and valleys, large fluctuations, short life, etc., achieve continuous and stable steam, and avoid kinetic energy loss , the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described below in conjunction with accompanying drawing and embodiment

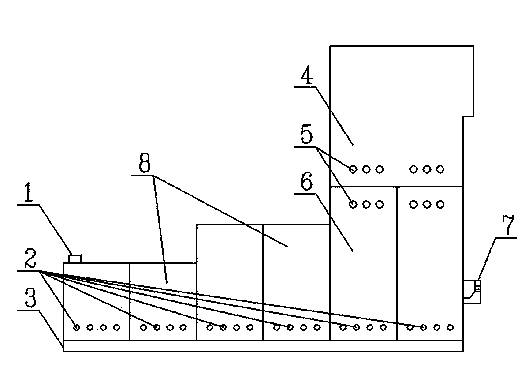

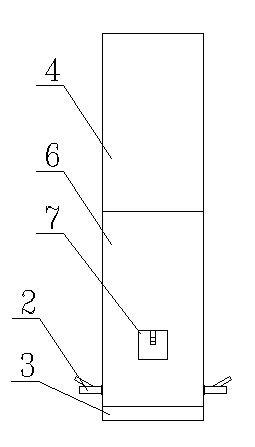

[0019] in accordance with figure 1 , figure 2 The specific implementation of the tunnel-type adjustable slag outlet continuous fuming furnace of the present invention is described below.

[0020] The tunnel-type adjustable slag port continuous fuming furnace disclosed in this embodiment includes a furnace 8, a tuyere 2, a feed port 1, a slag discharge port 7, and a straight-up flue 4, wherein the furnace 8 is designed as a tunnel structure; the tuyere 2 It is arranged on both sides of the bottom of the furnace 8. The feed port 1 and the slag discharge port 7 are placed at the first and last ends of the furnace. The height of the top of the furnace from the feed port 1 to the slag discharge port 7 is designed to rise in steps; 4 is arranged on the top of the slag discharge end 6 of the furnace; the height of the slag discharge port 7 is adjustable.

[0021] The cro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com