Shear type expansion anchor rod and application thereof

An expansion bolt and expansion plate technology, which is used in the installation of bolts, sheet pile walls, mining equipment, etc., can solve the problems of abandoned foundations, inability to use adhesives, reduced work efficiency and construction progress, etc. Good effect, improve the effect of anchoring effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

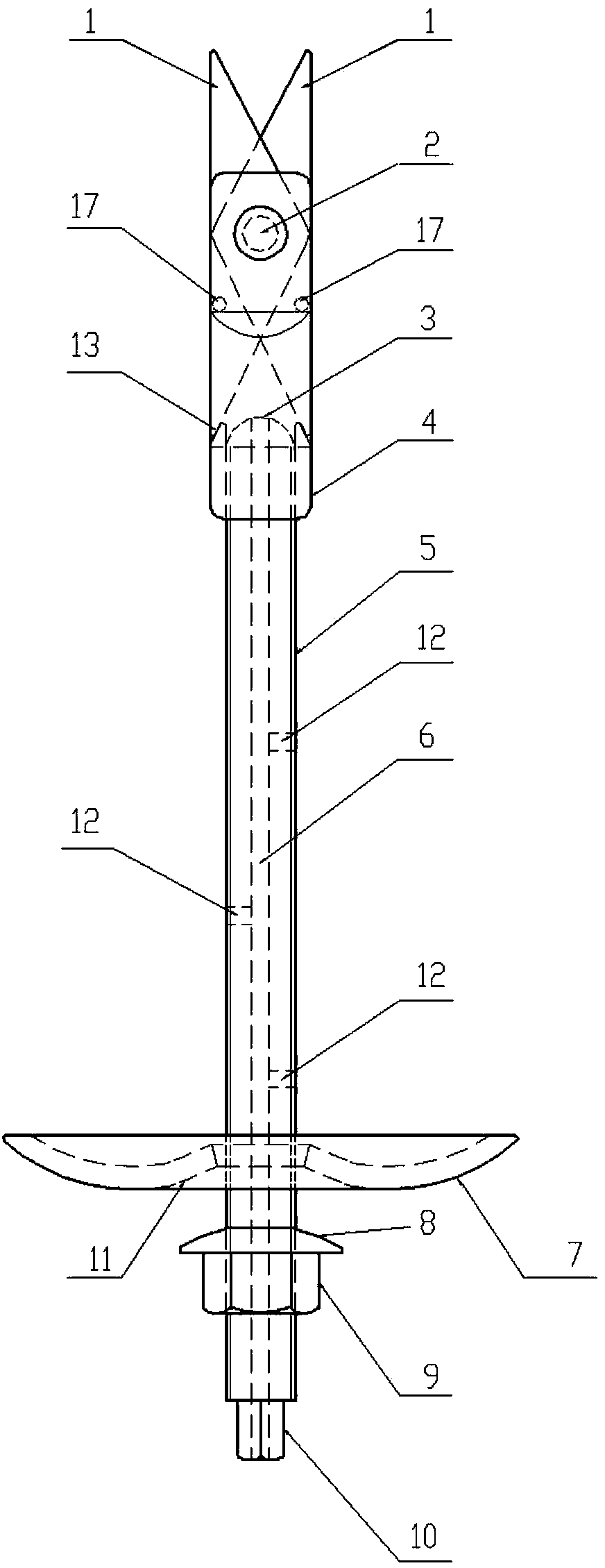

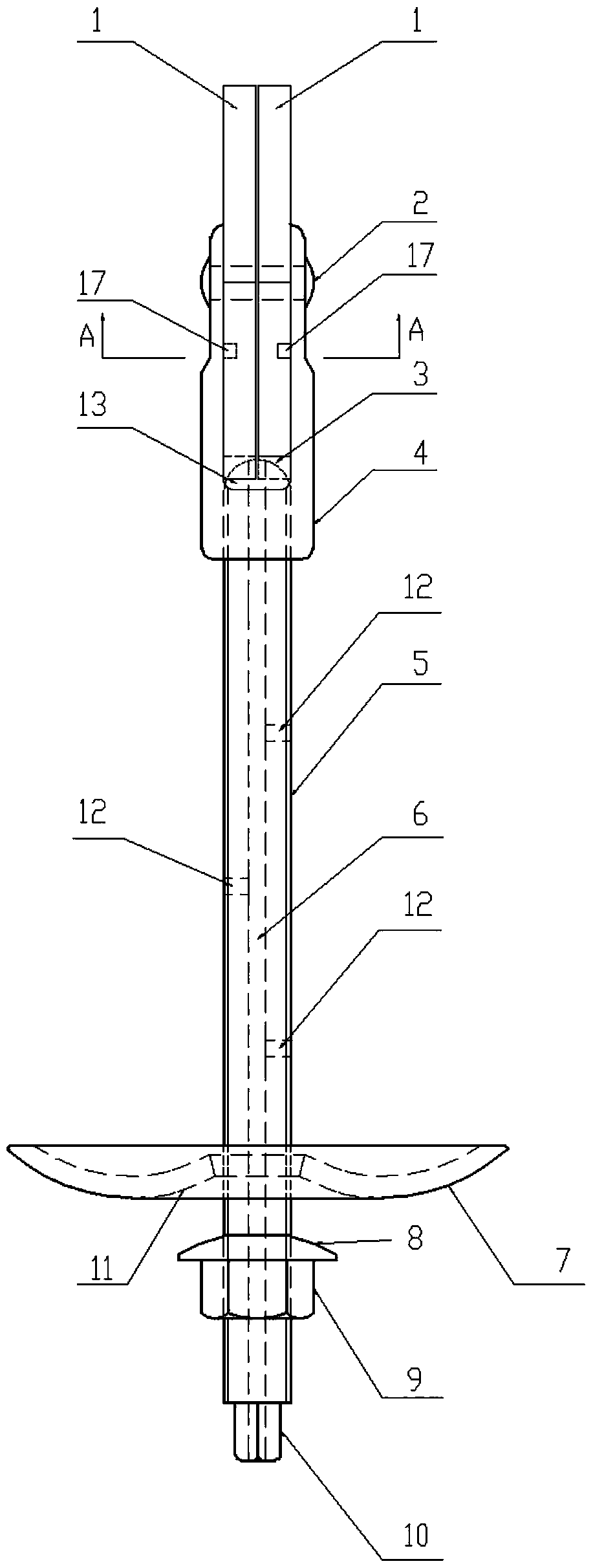

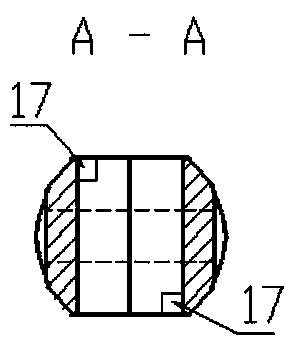

[0090] Such as figure 1 , 2 , 4, the present invention includes a lug nut support 4 and a screw 5 matched with the lug nut support 4, the lug nut support 4 has two oppositely arranged support plates, and hinge holes are arranged on the top of the support plate , the riveting shaft 2 is installed in the hinged hole; the two expansion plates 1 are combined and embedded between the two support plates of the lug nut bearing 4, and are hinged with the support plate through the riveting shaft 2; The inner edges and corners of the lower end slope of the expansion plate 1 contact, and the screw rod 5 can be screwed in to push the two expansion plates 1 to expand outwards respectively along the inner edges and corners of the lower end slope of the expansion plate 1 . Here, the distribution of the force points that push the expansion plate falls symmetrically on the arc surface of the screw end or the diameter line of the hemispherical head, or the projection line of the merged surface...

Embodiment 2

[0103] Such as Figure 7 , 8 As shown in and 9, the present embodiment is basically the same as Embodiment 1, the difference is that, in order to be suitable for anchoring with higher strength, the bridge 14 is consolidated at the upper ends of the two support plates of the lug nut bearing 4, so that the two The support plate is more stable and reliable; at the same time, the crossing bridge 14 is tapered, and its advantage is that the present invention can be directly driven into or pressed into the softer anchor matrix, and the function of the chisel head is integrated, including the head of the crossing bridge. And set the self-tapping thread on the side. Of course, the upper end surface of the bridge can be arc-shaped or flat, and anti-slip patterns or teeth can be set on the end surface.

[0104] Such as Figure 7 , 8 As shown in and 9, the expansion plate embedded in the lug nut support 4 is transformed into a special-shaped expansion plate 15 with one end being arc-sh...

Embodiment 3

[0106] Such as Figure 10 , 11 , 14, the present embodiment is basically the same as Embodiment 2, the difference is that, in order to be more convenient to use, the pre-drilling step is omitted, and a drill bit 18 is set on the upper end of the lug nut support 4, and the drill bit 18 is screwed on the belt. On the thread bridge 26. In this way, the present invention can be drilled directly into the anchor matrix by self-cutting.

[0107] At the same time, in order to facilitate the operations of drill bit drilling and anchorage expansion without interfering with each other, a self-locking device A1 is provided at the matching part of the screw rod and the lug nut support. Specifically, two structural schemes are provided:

[0108] The first option: if Figure 12 , 13 And shown in 34, self-locking device A1 comprises the dead bolt chamber 23 that the head side of screw rod 5 is provided with, dead bolt 29 and stage clip 24 are installed in the dead bolt chamber 23, open l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com