Method for dynamically controlling furnace temperature of heating furnace based on time sensitivity

A technology of dynamic heating and control method, applied in the field of metallurgy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Each table is graded according to steel type and temperature (every 50°C).

[0022] Specific heat calculation:

[0023] hour

[0024] hour

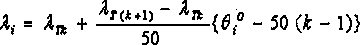

[0025] When ( k = 1~27 )

[0026]

[0027] in, : Average temperature of slab (°C); : Average specific heat (Kcal / kg℃); : Specific heat in the table (Kcal / kg℃); : slab identification; : Specific heat stratification level in the table

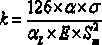

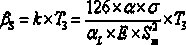

[0028] Calculation of heat transfer coefficient

[0029] hour

[0030] hour

[0031] When ( k = 1~27 )

[0032]

[0033] in, : Average temperature of slab (°C); : Average thermal conductivity (Kcal / mhr℃); : thermal conductivity in the table (Kcal / mhr℃); : slab identification; : Specific heat stratification level in the table

[0034] Step 3: Calculate the average physical parameters of the slab in each section according to the predicted shortest furnace time of the slab, the actual temperature of the slab and the physical length of each section of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com