System and method for automatically and quantitatively analyzing coal rock ray plate fracture

A quantitative analysis and analysis system technology, applied in the analysis of materials, material analysis through optical means, measuring devices, etc., can solve the problems of inability to clearly distinguish cracks or lanes in coal and rock light slices, limitations and inaccuracies, and analysis items Limited and other problems, to achieve rich and accurate test results, reduce manual time-consuming, and increase the effect of analysis items

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

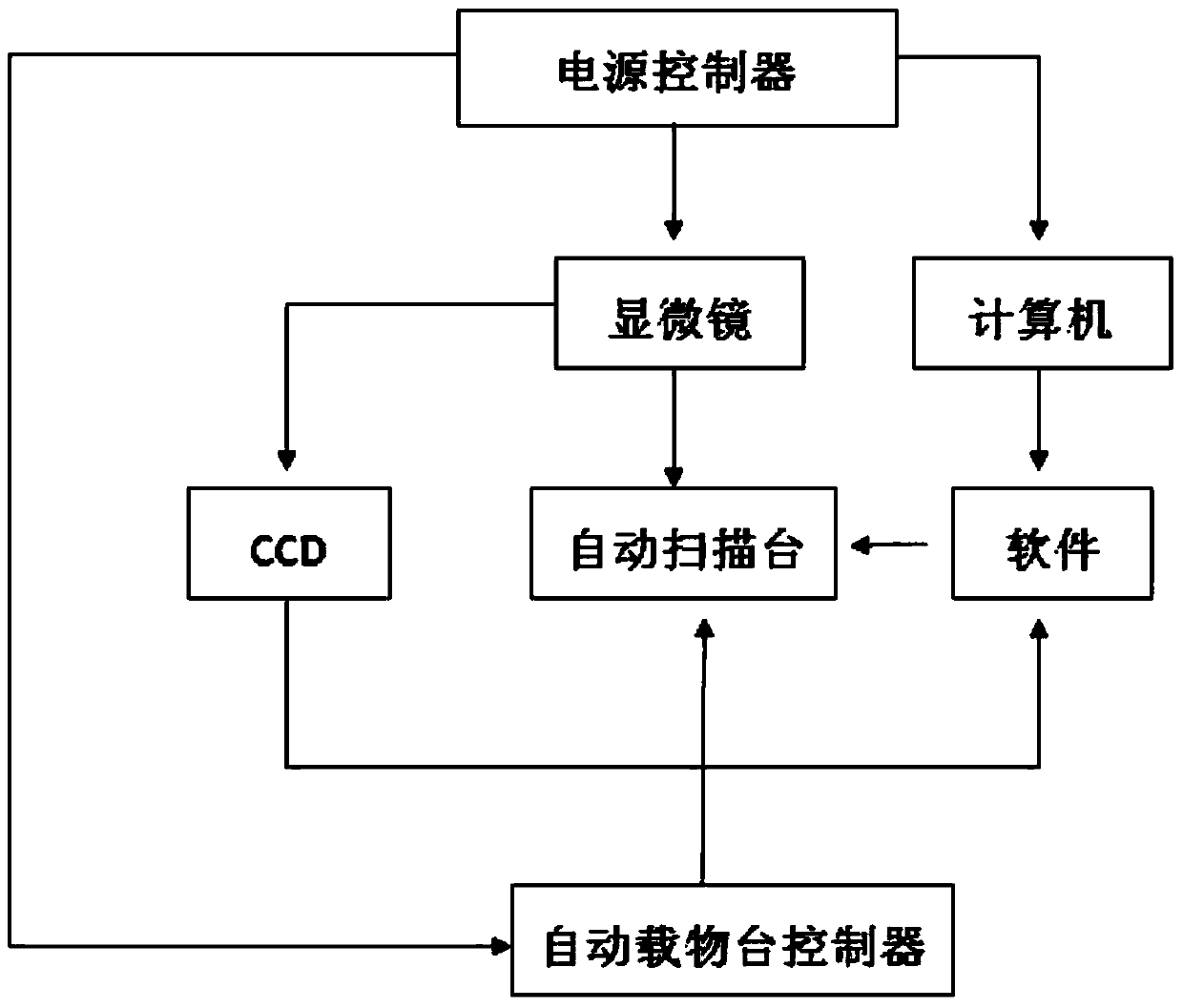

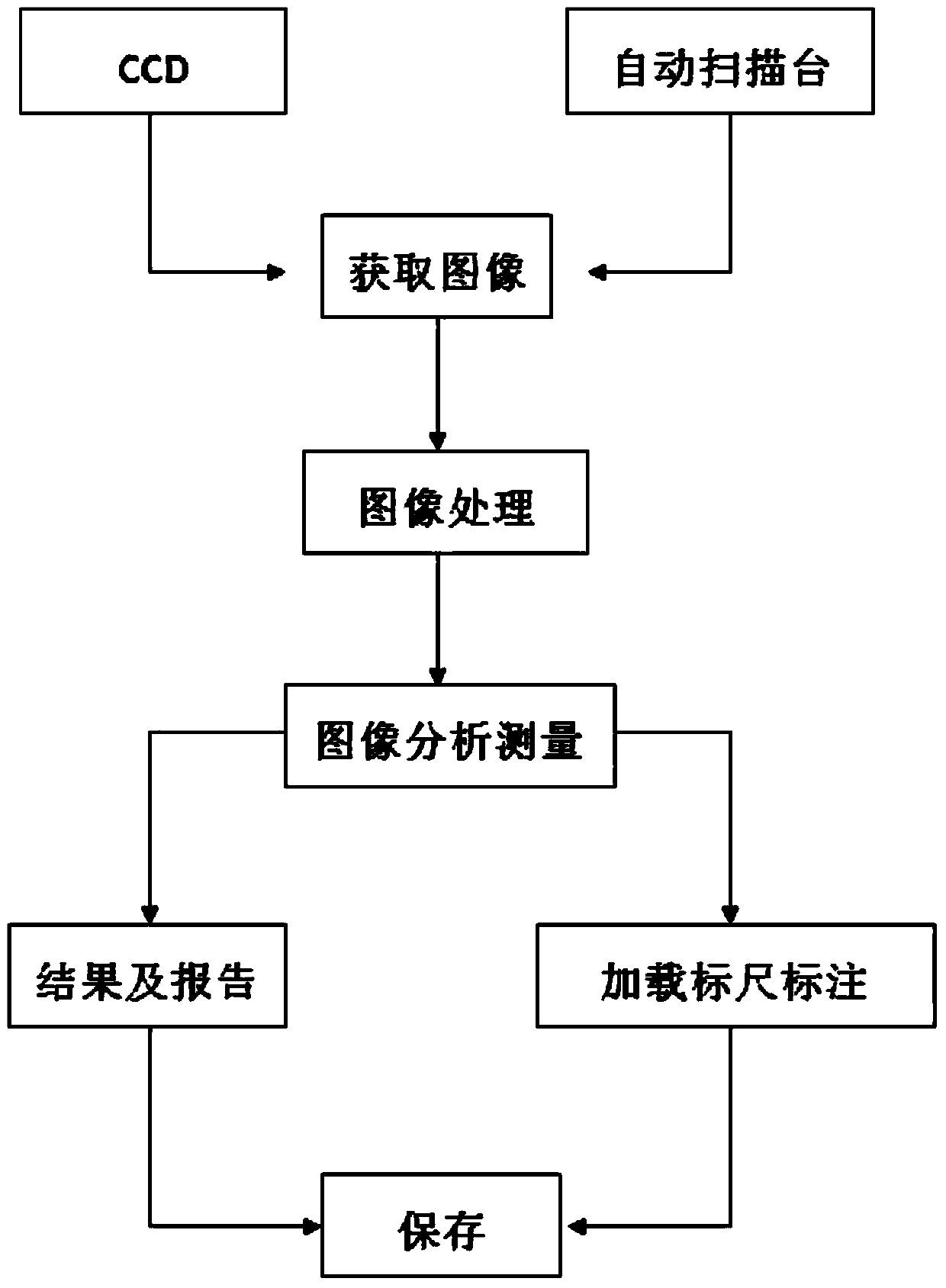

[0031] The principle adopted in the present invention is as follows: the present invention links the microscope automatic platform control system and / or microscopic image analysis system to the fluorescence microscope, uses the microscope automatic platform control system to control the moving direction and distance of the fluorescence microscope stage, and completes the image under the microscope The automatic conversion of the field of view and the panoramic scanning and collection of images; at the same time, the microscopic image analysis system is used to display the images under the microscope on the computer monitor, and then process and analyze them, and finally realize the automatic quantitative characterization of coal rock optical slice cracks.

[0032] The microscope automatic platform control system includes the following areas: toolbar area, image display area, platform control and coordinate point area; wherein, the toolbar area includes the pre-parameter setting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com