Method for automatically detecting adhesion defect of label of flat wine bottle

A label pasting and automatic detection technology, which is applied in the direction of optical testing for flaws/defects, can solve problems such as label pasting defects that cannot be flattened, and achieve fast results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

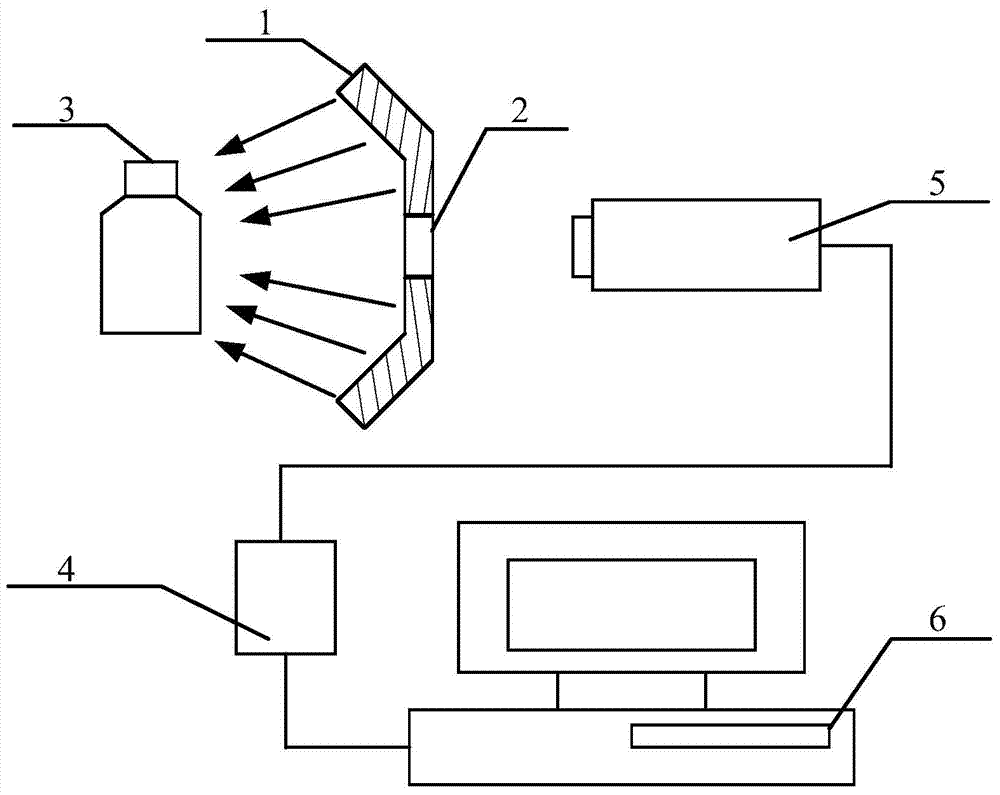

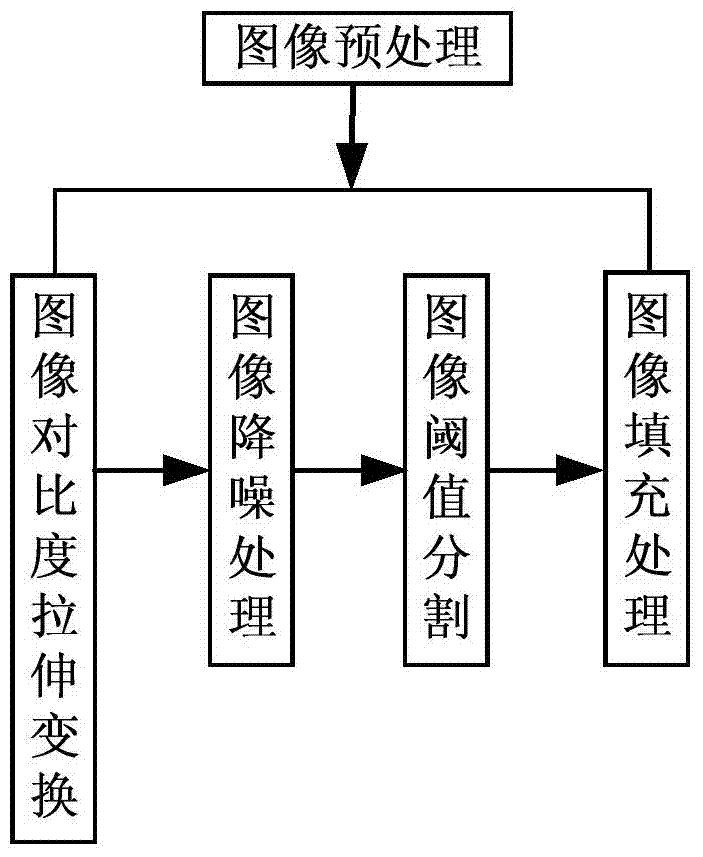

[0061] Such as figure 1 As shown in the lighting imaging system, the white light emitted by the LED ring light 1 passes through the small hole 2 and shines on the flat wine bottle 3, and then the CCD camera obtains the image through the reflected light, and then the computer 6 preprocesses the obtained image , and finally calculate the pose relationship between the special point and the label in the preprocessed image, and compare it with the correct pose relationship between the special point and the label in reality, so as to obtain the result.

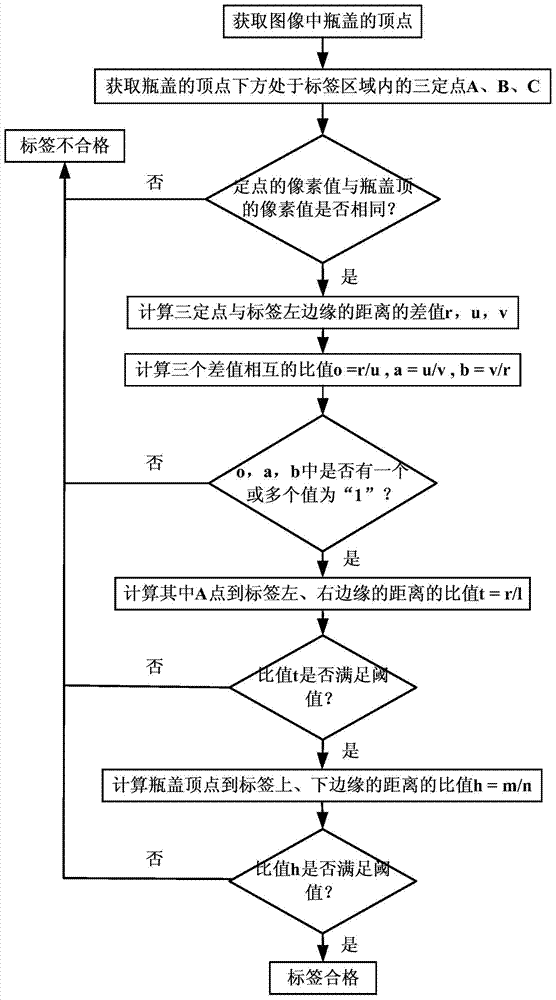

[0062] Such as Figure 4 As shown, the implementation steps are as follows:

[0063] 1. Find the midpoint coordinates of the top edge of the bottle cap area to determine the bottle cap vertex 7 and the central axis of the flat wine bottle, and then use the pose relationship between the bottle cap area and the label area when the label is correctly pasted in practice to find the label area There are three other points located direc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com