Horizontal fetching and placing system of two-phase solar energy wafer and a fetching and placing method thereof

A solar energy, two-stage technology, applied in the direction of conveyor objects, sustainable manufacturing/processing, electrical components, etc., can solve problems such as cracking, not stable bonding, wafer drop, etc., to reduce the probability of collision fragments, reduce risk, avoiding the effect of adsorption instability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

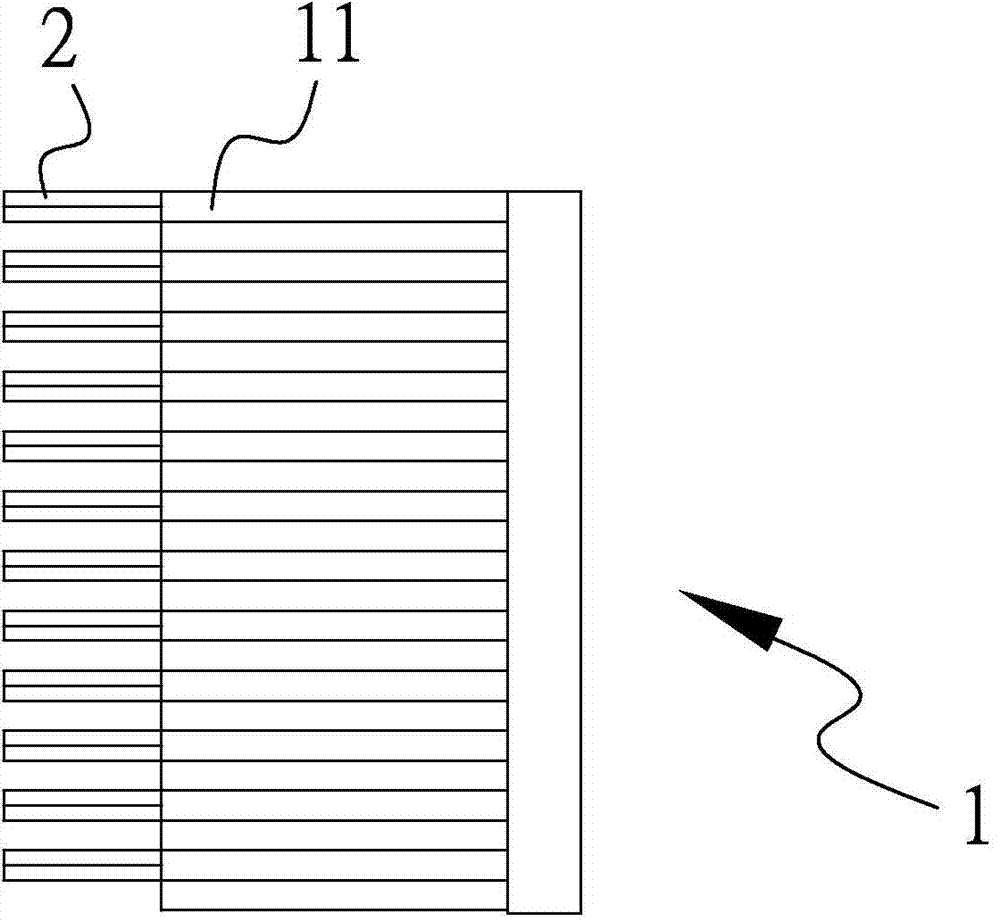

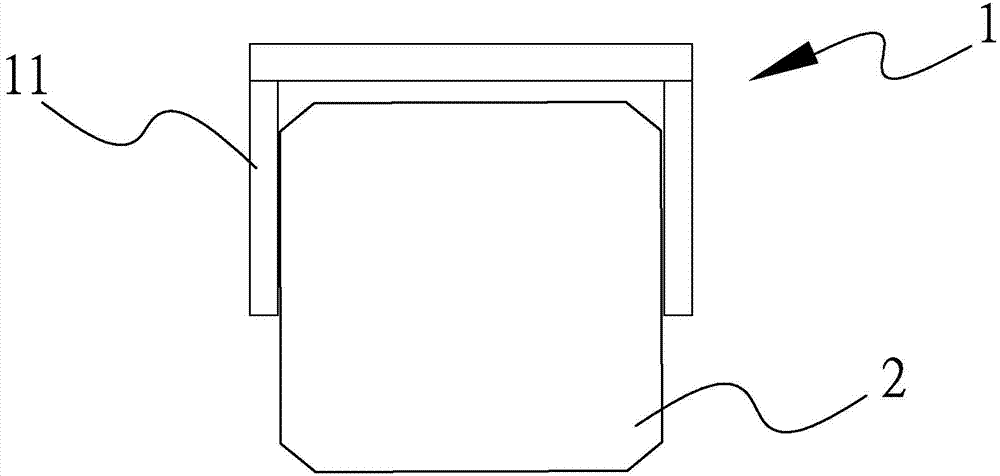

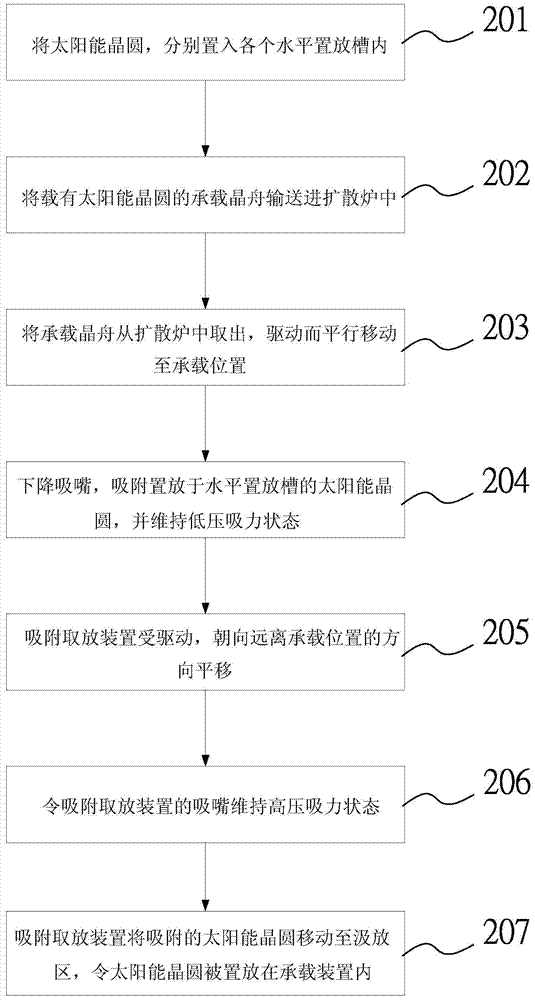

[0037] The first preferred embodiment of a two-stage solar wafer horizontal pick-and-place system and its pick-and-place method of the present invention, such as image 3 , Figure 4 and Figure 5 As shown, it is mainly for picking up and placing solar wafers 5, including an adsorption pick-and-place device 31, a drive device 32 and a processing device 33 for control, wherein the drive device 32 includes a set of actuating slide rails 321, and the adsorption pick-and-place device 31 includes A set of suction nozzles 311, and through the suction nozzles 311, take and place the solar wafer 5 by means of vacuum suction / removal suction. In this example, the horizontal pick and place system is to pick up a single solar wafer from the carrier wafer boat 4 5, and then transferred to a carrier device 6, and the position of the carrier device 6 is defined as the drain area 60 in the present invention, and the inside of the carrier wafer boat 4 is formed with a plurality of horizontal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com