Niobium and titanium flange device with superconducting cavity suitable for two types of washers

A technology of superconducting cavity and flange, applied in accelerators, electrical components, etc., can solve the problems of difficult cleaning of indium wire and unusable cavity, so as to save manpower for installation and dismantling, save manpower and time, and reduce use Quantity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

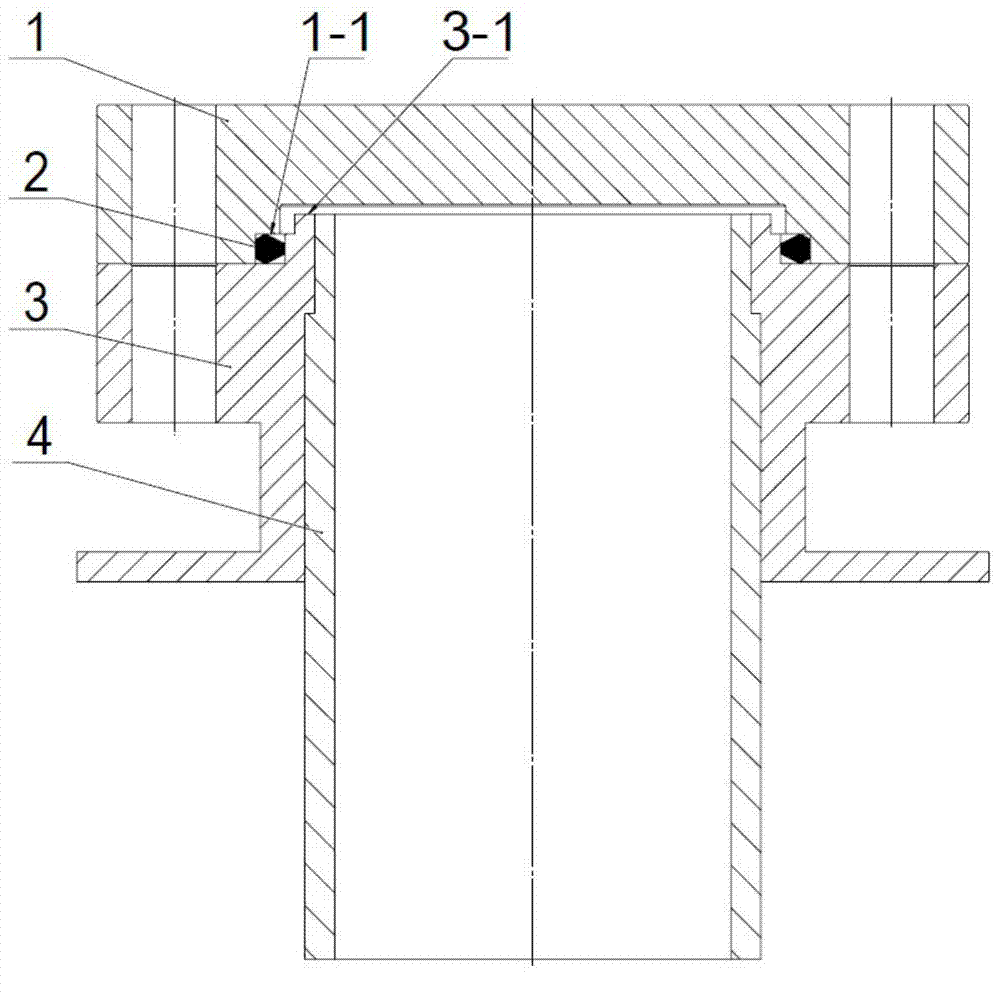

[0017] Example 1: see figure 1 , a superconducting cavity niobium-titanium flange device suitable for magnesium-aluminum alloy sealing gaskets, including a lower flange 3 connected by an upper flange 1 and a niobium pipe fitting 4 on the niobium cavity, and on the sealing surface of the upper flange 1 There is a right-angle notch 1-1 on the top, and a boss 3-1 is arranged on the sealing surface of the lower flange 3. The cavity formed by the right-angle notch 1-1, the sealing surface of the lower flange 3 and the side of the boss 3-1 is a sealed cavity , which is provided with a sealing ring 2.

[0018] The sealing ring 2 is a magnesium-aluminum alloy sealing gasket.

Embodiment 2

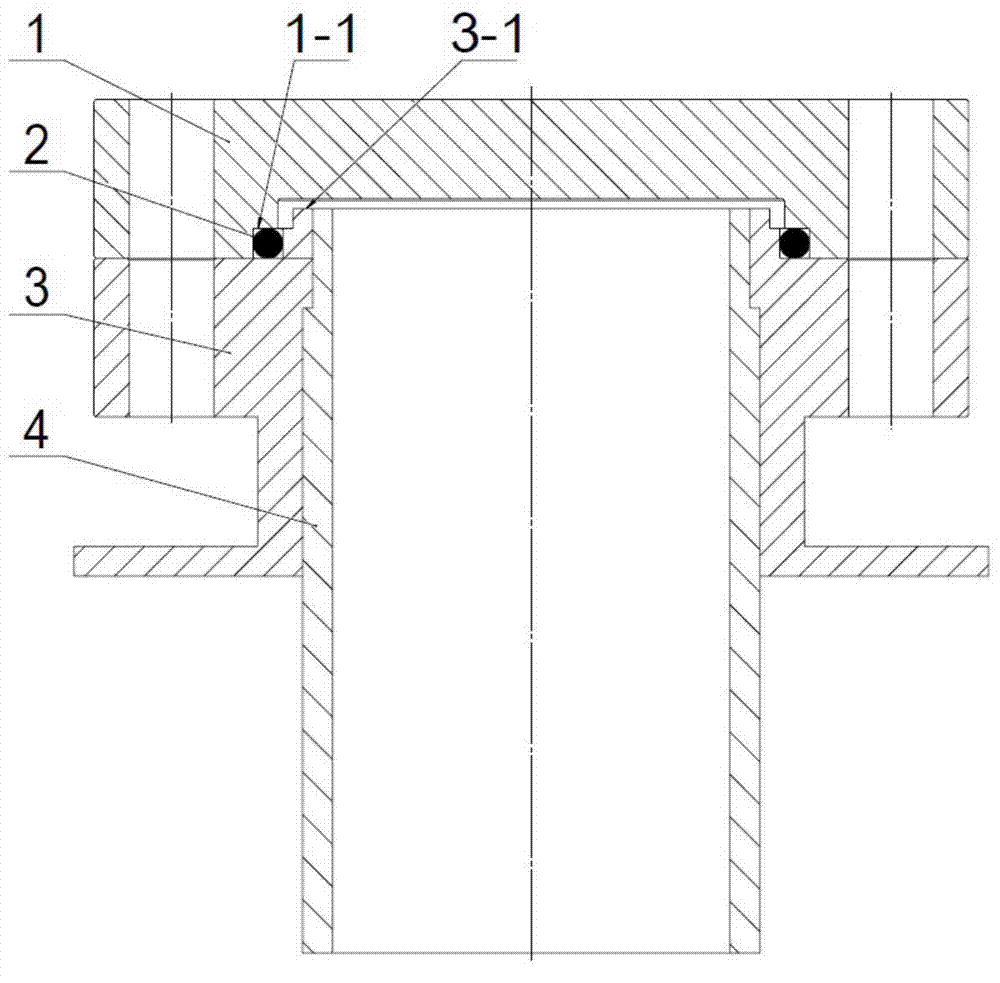

[0019] Example 2: see figure 2 , a superconducting cavity niobium-titanium flange device suitable for gaskets, the sealing ring 2 is an indium wire sealing gasket.

[0020] All the other structures are the same as in Example 1.

[0021] All the flanges in the present invention are first assembled with magnesium-aluminum alloy gasket flanges, checked with a vacuum leak detector, and if any flanges that cannot be sealed are sealed with indium wire gaskets. In this way, only a small amount of indium wire-sealed surfaces need to be processed during disassembly. Compared with all indium wire seals, the present invention saves processing time and manpower; compared with magnesium-aluminum alloy gaskets, it does not need to frequently return to the factory for maintenance of the sealing surface.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com