Laboratory intelligent reaction system and its control method

A reaction system and laboratory technology, applied in the field of laboratory intelligent reaction system and its control, intelligent reaction system, can solve problems such as large difference in results, large influence, and many influencing factors, so as to reduce the influence, shorten the experiment time, The effect of improving experimental efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

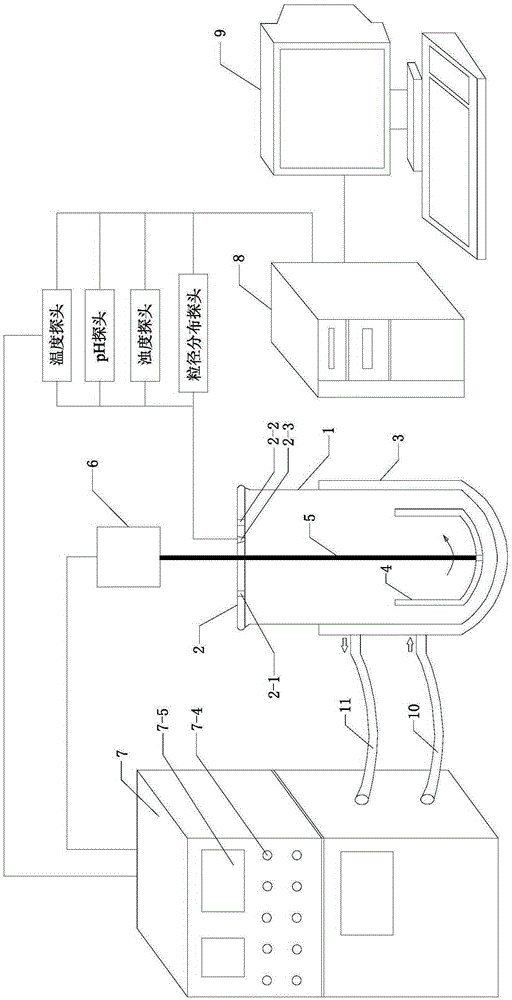

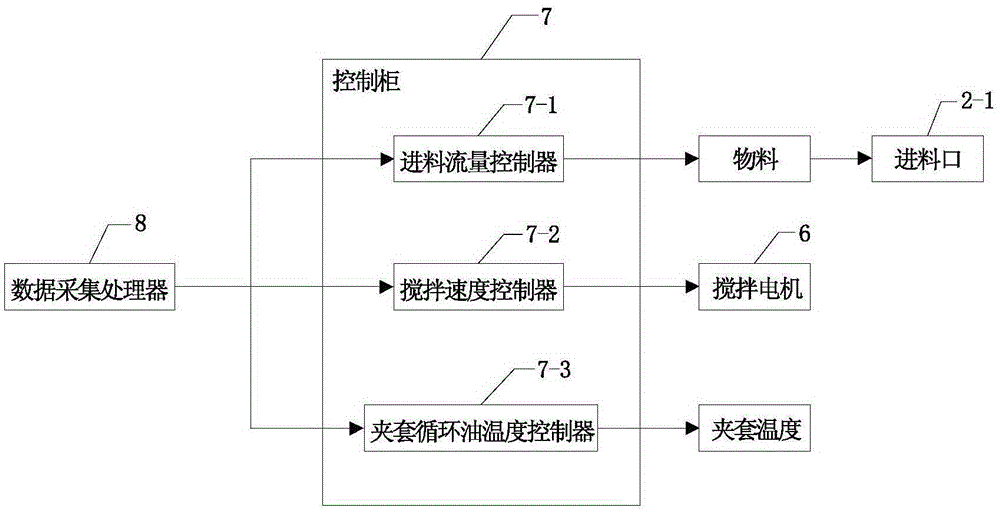

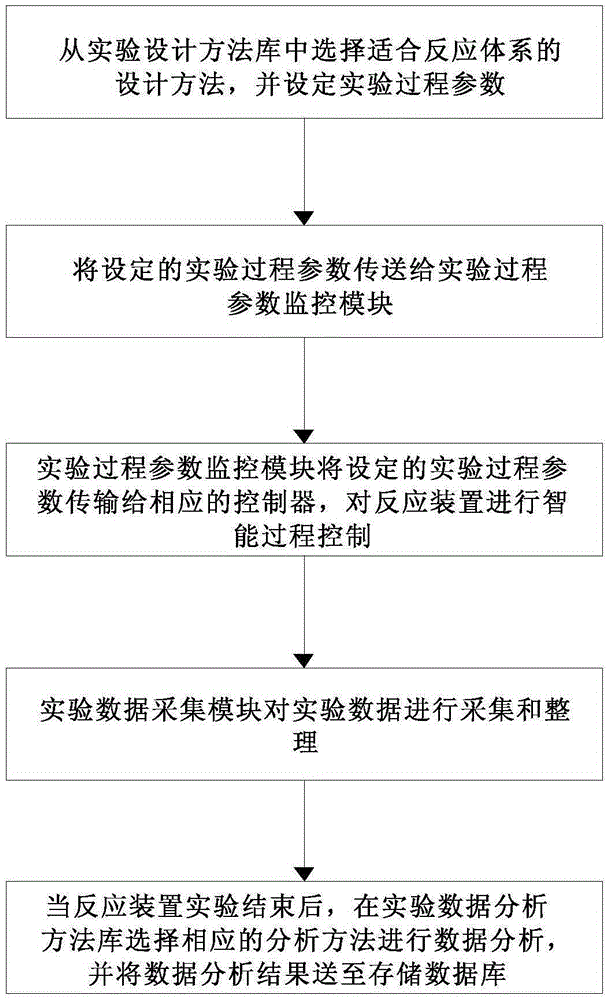

[0043] Such as figure 1 and figure 2 As shown, the laboratory intelligent reaction system of the present embodiment includes a reaction device, an automatic control device and a central monitoring platform, the reaction device is a jacketed reactor, and the jacketed reactor includes a kettle body 1 and a lid 2 , jacket 3, stirring paddle 4, stirring shaft 5 and stirring motor 6, the kettle cover 2 is arranged on the top of the kettle body 1, and is provided with a feed port 2-1, a discharge port 2-2 and a probe installation port 2 -3, the jacket 3 is arranged on the outer wall of the kettle body 1, the stirring paddle 4 is connected to the stirring shaft 5, the stirring shaft 5 passes through the kettle cover 2 and is connected to the stirring motor 6, and the probe installation port 2- 3 Temperature probe, pH probe, turbidity probe and particle size distribution probe can be installed; the automatic control device includes a control cabinet 7, which is divided into upper an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com