Linear cutting guide roller assembly capable of prolonging service life

A technology of wire cutting and guide wheel, which is applied to the improvement field of wire cutting guide wheel assembly and wire cutting guide wheel assembly structure, can solve the problems of shortened life, poor effect, and bearing damage, so as to improve service life and improve Waterproof effect, good waterproof protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with accompanying drawing.

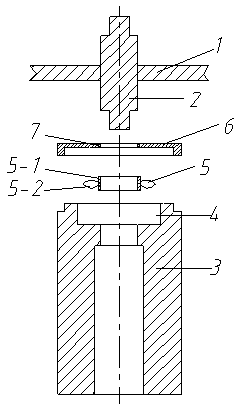

[0018] see figure 1 , as can be seen from the figure, the wire cutting guide wheel assembly of the present invention includes a guide wheel 1, a guide wheel shaft 2, a bearing and a guide wheel seat 3 (for convenience of expression, figure 1 The bearing is not drawn in the figure), the guide wheel 1 is installed on the guide wheel shaft 2, and the two ends of the guide wheel shaft are installed on the corresponding bearings. Outside the bearing is the guide wheel seat 3, that is, the bearing seat of the bearing. The guide wheel seat 3 is provided with a housing chamber 4 toward the middle of the guide wheel end face, and a water retaining fan assembly 5 is provided in the housing chamber 4, and the water retaining fan assembly 5 is composed of a central tube 5-1 and a central tube peripheral surface. It consists of 2-4 fan blades 5-2 evenly distributed on the top. A water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com