Modified electric knife sharpener

A knife grinder and electric technology, applied in grinding/polishing equipment, grinding/polishing safety devices, other manufacturing equipment/tools, etc., can solve the problems of reduced work efficiency, high labor intensity, inconvenient use, etc., to achieve Improved work efficiency, high safety performance, and convenient use conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

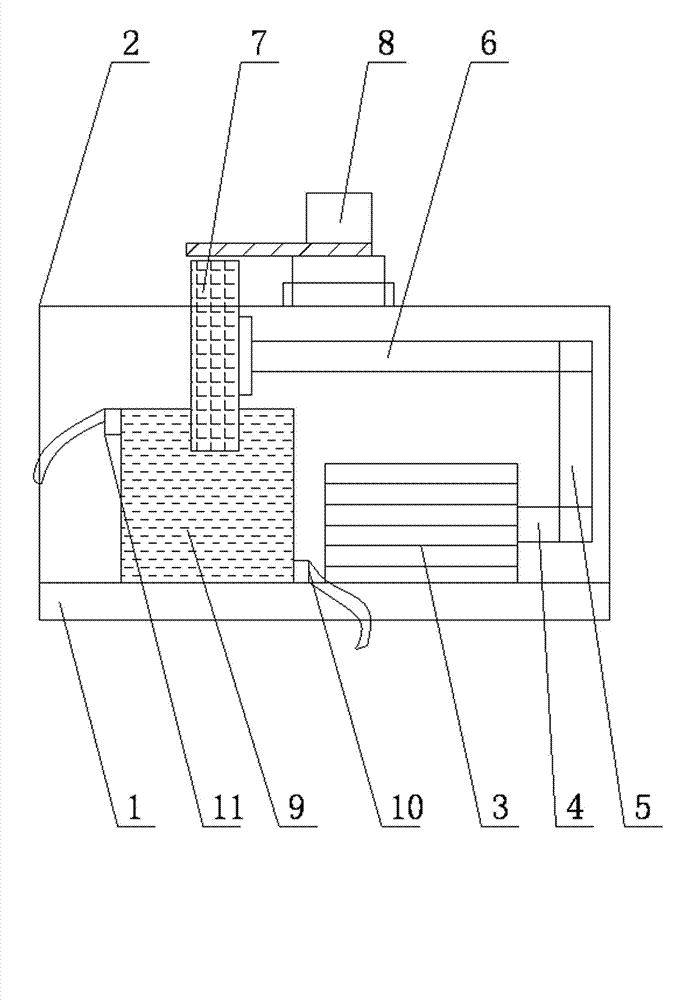

[0013] Such as figure 1 As shown, the improved electric sharpener of the present invention includes a base 1, a housing 2 is provided on the base 1, a motor 3 is provided on the inner base of the housing 2, and a motor shaft is provided on the motor 3 4. The motor shaft 4 is connected to the main shaft 6 through the transmission shaft 5, the end of the main shaft 6 is provided with a whetstone 7, and the top of the housing 2 is provided with a tool holder 8, and the tool holder 8 is a lifting tool holder 8. A cooling chamber 9 is provided on the lower base of the whetstone 7. There is no gap between the cooling chamber 9 and the whetstone 7. A water inlet 10 is provided at the bottom end of the cooling chamber 9. The cooling chamber 9 9. The other end of the top is provided with a water outlet 11. The 1 / 3 part of the diameter of the whetstone 7 is located outside the housing 2. The structure is simple and elegant, easy to use, high in safety performance, stable in work per...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com