Shaft part cutting and/or grinding processing clamp and processing method thereof

A technology for grinding processing and shaft parts, which is applied in the direction of grinding workpiece supports, machine tools designed for grinding the rotating surface of workpieces, manufacturing tools, etc., which can solve the problem of large processing errors, affecting work efficiency, and inconvenient processing of eccentric inner circles Or outer circle and other problems, to achieve the effect of widening the range of shaft diameter specifications, highlighting substantive features, and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

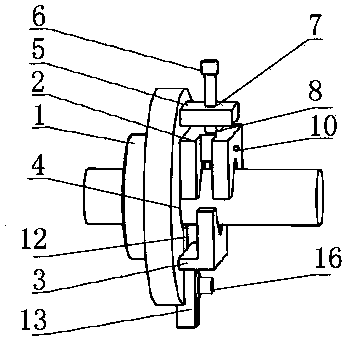

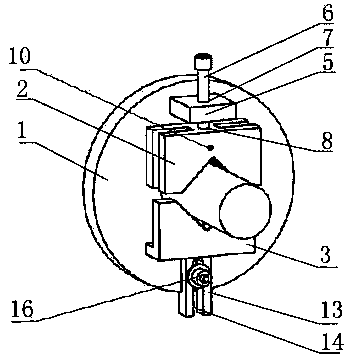

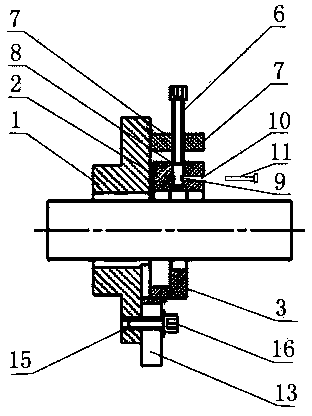

Embodiment 1

[0039] Such as Figure 6 As shown, on the universal cylindrical grinding machine, the outer circle of the processed parts is φ600-0.01 and the inner circle is φ600+0.01, and the coaxiality requirement with the reference outer circle of the part is φ80±0.01.

[0040] step:

[0041] 1. Install the chuck 1 of the fixture on the chuck of the universal cylindrical grinder, and use the dial indicator to find the center of the chuck 1;

[0042] 2. Put the part reference outer circle φ80±0.01 into the part through hole 4 in the middle of the chuck 1, place it between the upper clamping block 2 and the lower clamping block 3, adjust the position of the upper clamping block 2 and the lower clamping block 3, Clamp the outer circle of the part to φ80±0.01, and use the dial gauge to find the center of the outer circle of the part to φ80±0.01;

[0043] 3. Adjust the limit device to lock the upper clamping block 2 and the lower clamping block 3;

[0044] 4. Carry out grinding processing of ...

Embodiment 2

[0049] like Figure 7 As shown, on the universal cylindrical grinding machine, the outer circle of the processed part is φ600-0.01, and the eccentricity requirement of the part reference outer circle φ80±0.01 is e±0.05.

[0050] step:

[0051] 1. Install the chuck 1 of the fixture on the chuck of the universal cylindrical grinder, and use the dial indicator to find the center of the chuck 1;

[0052] 2. Put the part reference outer circle φ80±0.01 into the part through hole 4 in the middle of the chuck 1, place it between the upper clamping block 2 and the lower clamping block 3, adjust the position of the upper clamping block 2 and the lower clamping block 3, The outer circle of the clamping part is φ80±0.01, and at the same time, adjust the outer circle of the screw clamping part to φ80±0.01, and measure the runout of φ80±0.01 with a dial gauge until mmax-mmin=2 e (mmax-maximum run-out, mmin- minimum runout), tighten the bolt 16, lock the lower clamp 3, tighten the screw 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com