A kind of production method of permeable concrete

A production method and concrete technology, which is applied in the direction of climate sustainability, sustainable waste treatment, solid waste management, etc., can solve the problems of miscellaneous sources, irregular classification management, and loose quality control, etc., to increase the cohesive force , performance improvement, and the effect of increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The invention is a kind of permeable concrete mixed with PVA high-quality regenerated coarse aggregate. The concrete is composed of cement, high-quality regenerated coarse aggregate instead of 30% of the natural coarse aggregate, water, and additional additives determined according to performance. agent composition.

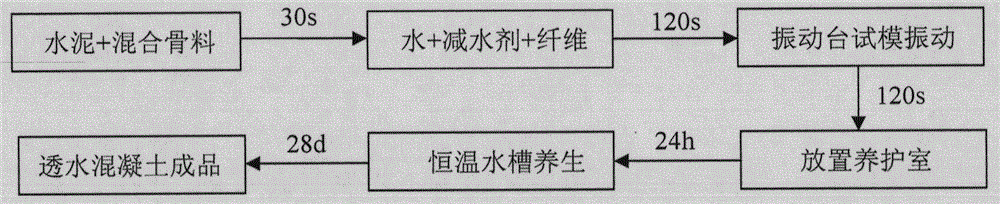

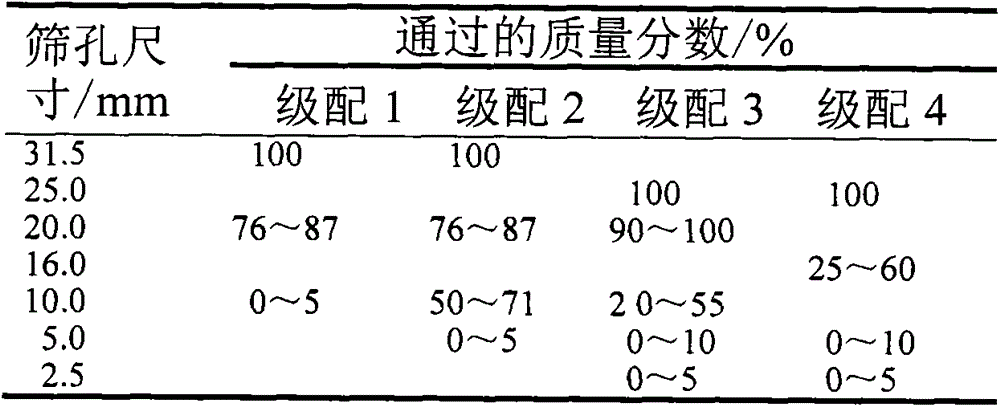

[0015] In conjunction with examples, the PVA reinforced high-quality regenerated coarse aggregate permeable concrete of the present invention is specifically described as follows: (1) 500kg chunks of old concrete are smashed into 2 block, then use a crusher to crush according to the maximum particle size of 50mm, and sieve the crushed aggregate to obtain the required 310kg of recycled coarse aggregate (2.5mm~16mm) and 13kg of recycled fine powder (particle size3 , 230.0kg / m 3 、69.0kg / m 3 , 3.45kg / m 3 , 4.6kg / m 3 . The preparation process is as follows: add polypropylene short fibers to the prepared polycarboxylate high-performance water reducer and stir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| osmotic coefficient | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com