High-strength butadiene-styrene rubber and preparation method thereof

A styrene-butadiene rubber and high-strength technology, applied in the chemical industry, can solve problems such as poor strength and low-temperature performance, and achieve the effects of improving strength and low-temperature performance, enhancing mutual viscosity, and enhancing compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Test formula

[0019] Recipe material

Dosage (parts by weight)

SBR

100

5

Initiator DCP

0.4

3

[0020] Preparation:

[0021] Add styrene-butadiene rubber, methacrylic acid, initiator, and stearate into the twin-screw extruder to extrude and granulate. The screw speed used during extrusion and granulation is 60 rpm; the temperature setting of the twin-screw extruder As shown in the table below:

[0022] area

barrel area

barrel two area

Barrel three zones

Barrel four zones

Barrel five zone

Barrel six zone

Head temperature

temperature ℃

100~110℃

115~125℃

120~130℃

140~150℃

145~155℃

140~150℃

145℃

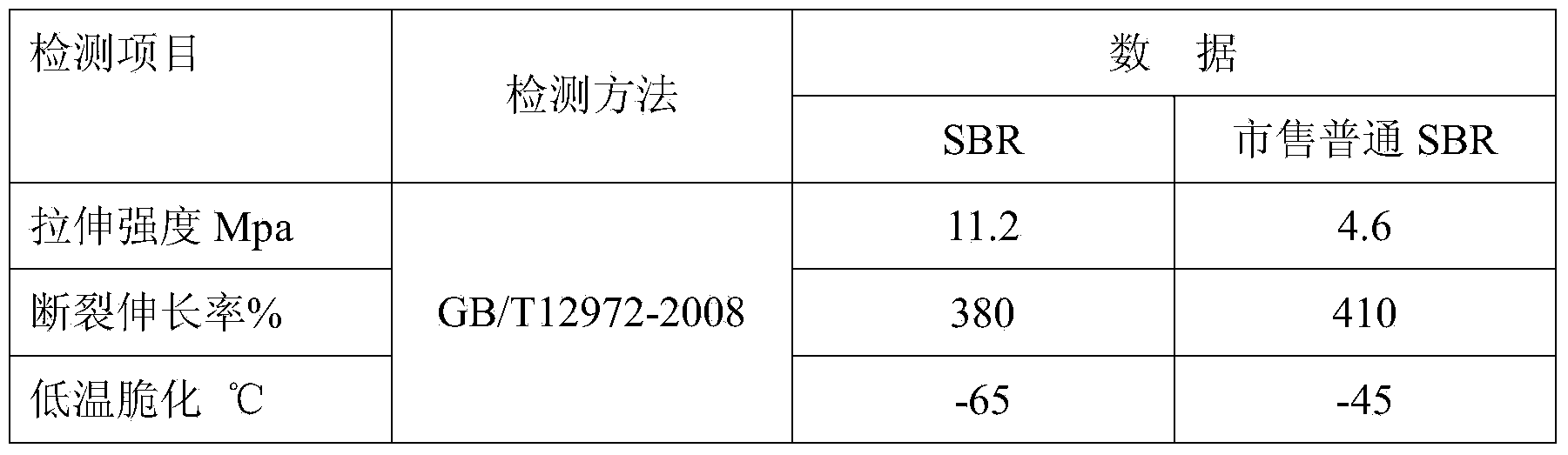

[0023] The following is a performance comparison table between the SBR prepared in Example 1 of the present invention and ordinary SBR. From the comparative data in Table 1, it can be seen that the SBR of the pr...

Embodiment 2

[0027] Test formula

[0028] Recipe material

Dosage (parts by weight)

SBR

100

4

Initiator DCP

0.6

Zinc stearate

2

[0029] Preparation:

[0030] Add styrene-butadiene rubber, methacrylic acid, initiator, and stearate into the twin-screw extruder to extrude and granulate. The screw speed used during extrusion and granulation is 80 rpm; the temperature setting of the twin-screw extruder As shown in the table below:

[0031] area

barrel area

barrel two area

Barrel three zones

Barrel four zones

Barrel five zone

Barrel six zone

Head temperature

temperature ℃

100~110℃

115~125℃

120~130℃

140~150℃

145~155℃

140~150℃

145℃

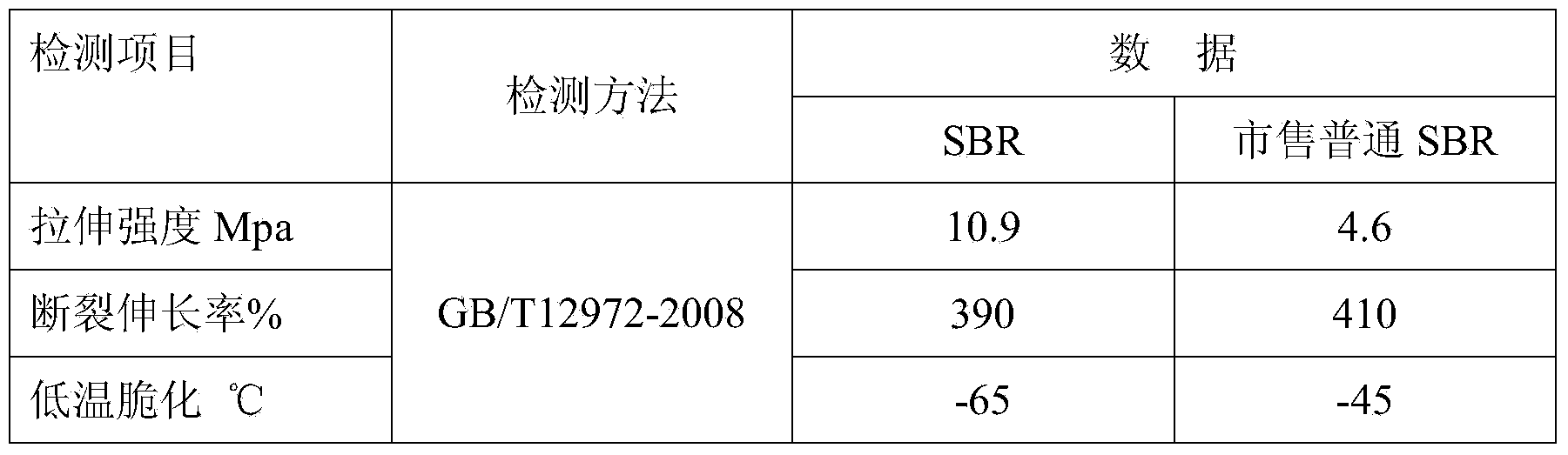

[0032] The following is a performance comparison table between the SBR prepared in Example 2 of the present invention and ordinary SBR. From the comparative data in Table 2, it can be seen that the SBR of the pr...

Embodiment 3

[0036] Test formula

[0037] Recipe material

Dosage (parts by weight)

SBR

105

3

Initiator DCP

0.5

Zinc stearate

3

Triallyl cyanurate

0.5

0.5

[0038] Preparation:

[0039] Add styrene-butadiene rubber, methacrylic acid, initiator, stearate, triallyl cyanurate, and tert-butyl peroxycumene into a twin-screw extruder to extrude granules. The screw speed adopted during pelleting is 70 rpm; the temperature settings of the twin-screw extruder are shown in the table below:

[0040] area

barrel area

barrel two area

Barrel three zones

Barrel four zones

Barrel five zone

Barrel six zone

Head temperature

temperature ℃

100~110℃

115~125℃

120~130℃

140~150℃

145~155℃

140~150℃

145℃

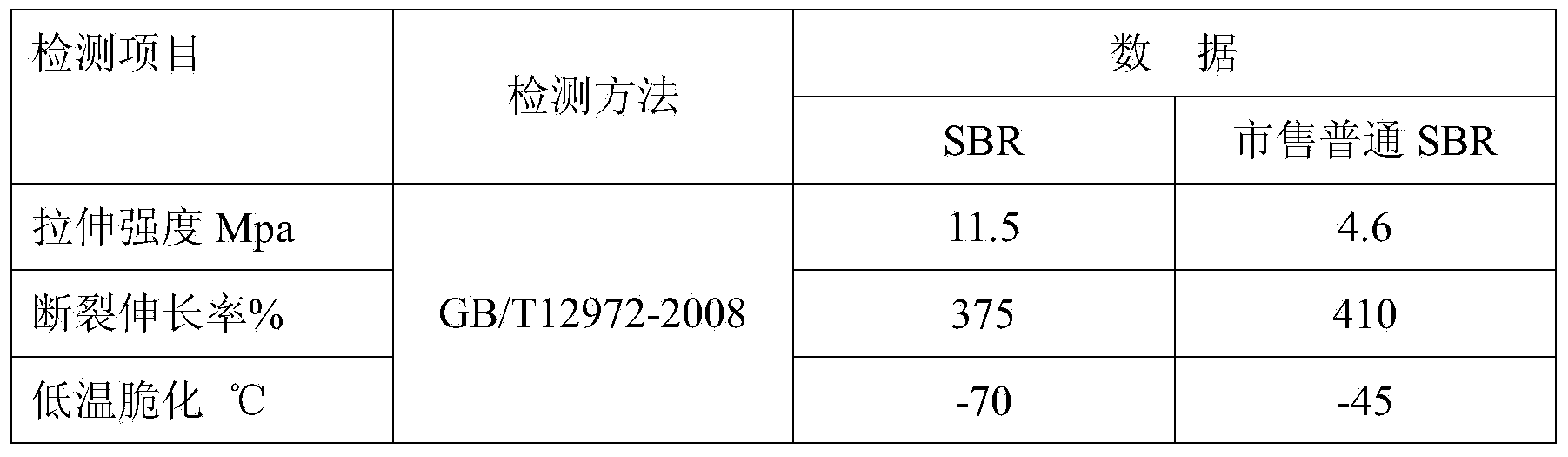

[0041] The following is a performance comparison table between the SBR prepared in Example 3 of the present ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com