Carbon black master batch for herbicide-containing plastic mulching films and preparation method thereof

A technology of carbon black and carbon black masterbatch for weeding mulch, which is applied in the field of weeding mulch, can solve the problems of low carbon black concentration, poor quality of black mulch, and low light transmittance of weeding mulch, and achieve the effect of simple operation and pollution reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

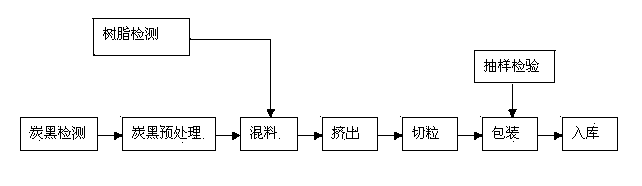

Method used

Image

Examples

Embodiment 1-14

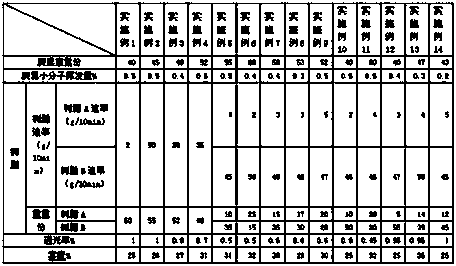

[0036] Adopt above-mentioned concrete mode of operation, coating agent is 1-2% of granulation carbon black weight part, the carbon black masterbatch concrete component and each component weight part of preparation weeding film among the present invention are as follows table 1:

[0037] Table 1

[0038]

[0039] In the above examples, those whose melt mass flow rate is (2-5) g / 10min are group A, and those whose melt mass flow rate is (45-50) g / 10min are group B.

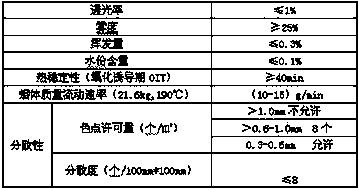

[0040] Product general performance index of the present invention is as follows table 2:

[0041] Table 2

[0042]

[0043]The masterbatch carbon black concentration of the present invention reaches 40-60%, which ensures the blackness of the weeding film blown by the present invention. Its light transmittance ≤ 1%, haze ≥ 25%, high light resistance, completely blocks the sunlight necessary for weed growth and photosynthesis, so as to achieve more than 95% weeding effect and reduce environmental pollution. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com