A thermal insulation system and its material preparation method

A thermal insulation and system technology, applied in the direction of thermal insulation, reflective/signal coatings, building components, etc., can solve the problems of inability to prevent energy transmission, less dosing of phase change materials, and inability to absorb energy, so as to avoid indoor temperature The effect of reducing, increasing the amount of mixing, and increasing the heat storage energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The chemical reagents and materials used in the present invention are commercially available, and will not be described in detail below.

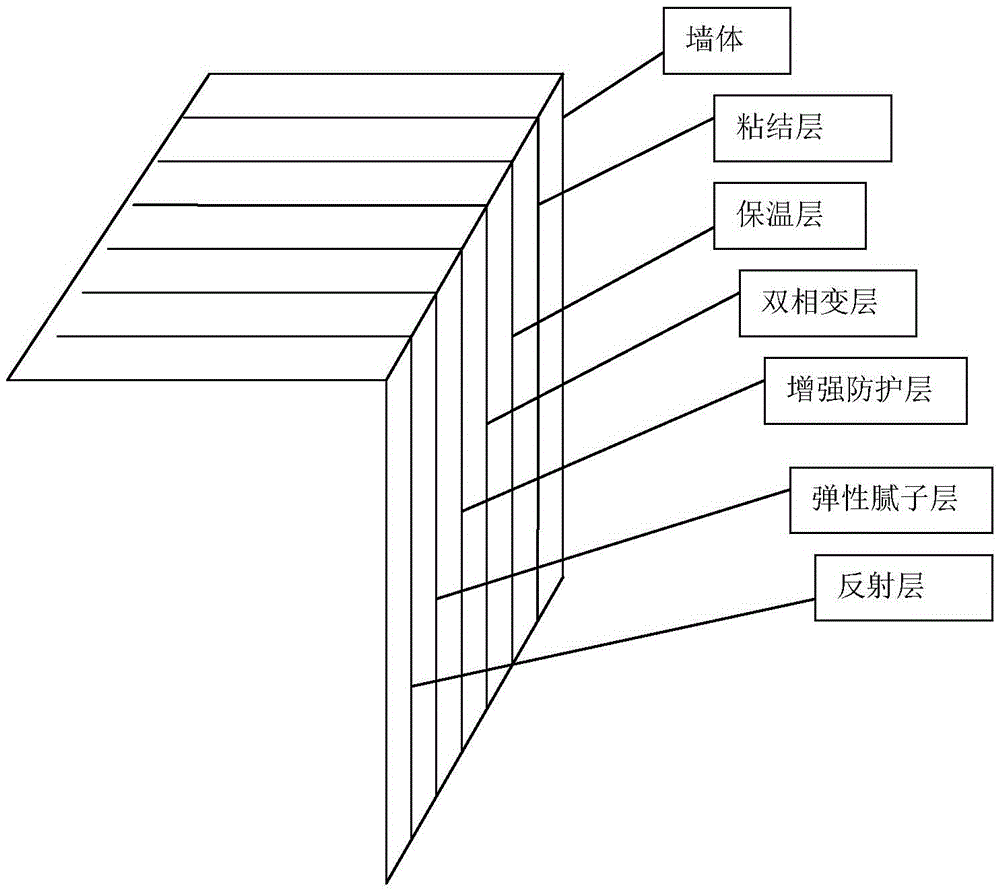

[0031] The thermal insulation system of this embodiment is shown in Figure 1. It is composed of an adhesive layer, an insulating layer, a dual phase change layer, a reinforced protective layer, an elastic putty layer and a reflective layer arranged in sequence outward from the wall, wherein the adhesive layer Adhesive mortar is used, the thermal insulation layer is made of expanded polystyrene board, the reinforced protective layer is made of anti-crack mortar and alkali-resistant mesh cloth, the elastic putty layer is made of external wall elastic putty, the reflective layer is made of high-performance heat-insulating reflective coating, the thermal insulation layer and the double-layer The phase change layers are bonded with polyurethane adhesive, and the structure of the reinforced protective layer is anti-crack mortar, alkali-resi...

Embodiment 2

[0042] The thermal insulation system of this embodiment is shown in Figure 1. It is composed of an adhesive layer, an insulating layer, a dual phase change layer, a reinforced protective layer, an elastic putty layer and a reflective layer arranged in sequence outward from the wall, wherein the adhesive layer Adhesive mortar is used, the insulation layer is made of extruded polystyrene board, the reinforced protective layer is made of anti-crack mortar and alkali-resistant mesh cloth, the elastic putty layer is made of external wall elastic putty, and the reflective layer is made of high-performance heat-insulating reflective coating. The phase change layers are bonded with epoxy resin adhesive. The structure of the reinforced protective layer is anti-crack mortar, alkali-resistant mesh cloth, and anti-crack mortar. The bonding area of the bonding layer and the insulation layer reaches 50%. The bonding area between the layer and the dual phase change layer reaches 60%. Where...

Embodiment 3

[0053] The thermal insulation system of this embodiment is shown in Figure 1. It is composed of an adhesive layer, an insulating layer, a dual phase change layer, a reinforced protective layer, an elastic putty layer and a reflective layer arranged in sequence outward from the wall, wherein the adhesive layer Adhesive mortar is used, the insulation layer is made of phenolic board, the reinforced protective layer is made of anti-crack mortar and alkali-resistant mesh cloth, the elastic putty layer is made of elastic putty for the outer wall, and the reflective layer is made of high-performance heat-insulating reflective coating. Modified phenolic adhesive is bonded between them, and the structure of the reinforced protective layer is anti-crack mortar, alkali-resistant mesh cloth, and anti-crack mortar. The bonding area of the adhesive layer and the insulation layer reaches 60%. The bonded area of the layers reaches 75%. Wherein, the dual-phase change layer is composed of d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com