Turbo supercharged engine intake manifold of integrated intercooler

A technology of turbocharging and intake manifold, applied in the direction of machines/engines, engine components, combustion engines, etc., can solve problems such as unfavorable engine instantaneous response performance, energy loss and waste, and increase manufacturing costs, so as to optimize the engine compartment Effects of layout, reduced number of parts, reduced length and capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

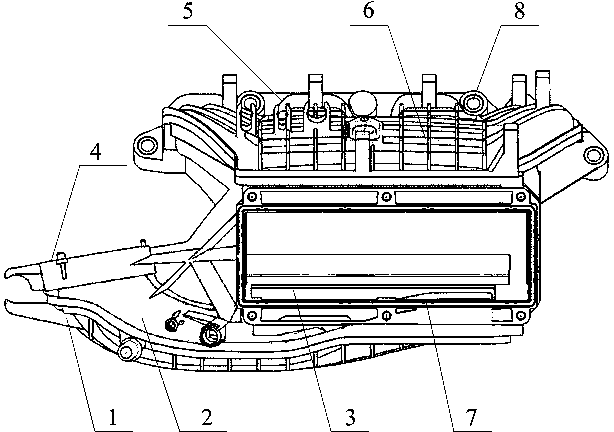

[0018] The intake manifold of a turbocharged engine integrating an intercooler in this embodiment, such as figure 1 As shown, it is connected between the engine throttle and the engine cylinder head, including the intercooler arranged in the intake manifold of the turbocharged engine. The intake port of the intake manifold of the turbocharged engine is separated from the intercooler connected. The isolated air channel is an air flow channel formed by welding the injection molded lower shell 1 , the injection molded middle shell 2 and the injection molded diversion groove 3 . An intercooler sealing ring 7 is arranged between the isolated air passage and the intercooler. The intake port 4 of the turbocharged engine intake manifold is connected with the engine throttle, and the gas outlet 5 of the turbocharged engine intake manifold is connected with the engine cylinder head. A throttle sealing ring is provided between the intake port 4 of the intake manifold of the turbocharge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com