High pressure three screw pump

A three-screw pump and screw technology, applied in pumps, rotary piston pumps, rotary piston machines, etc., can solve the problems of difficult screw hole machining, difficult to guarantee machining accuracy, and reduced volumetric efficiency, and reduce casting defects. The effect of improving volumetric efficiency and reducing inner hole clearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described through the embodiments below in conjunction with the accompanying drawings.

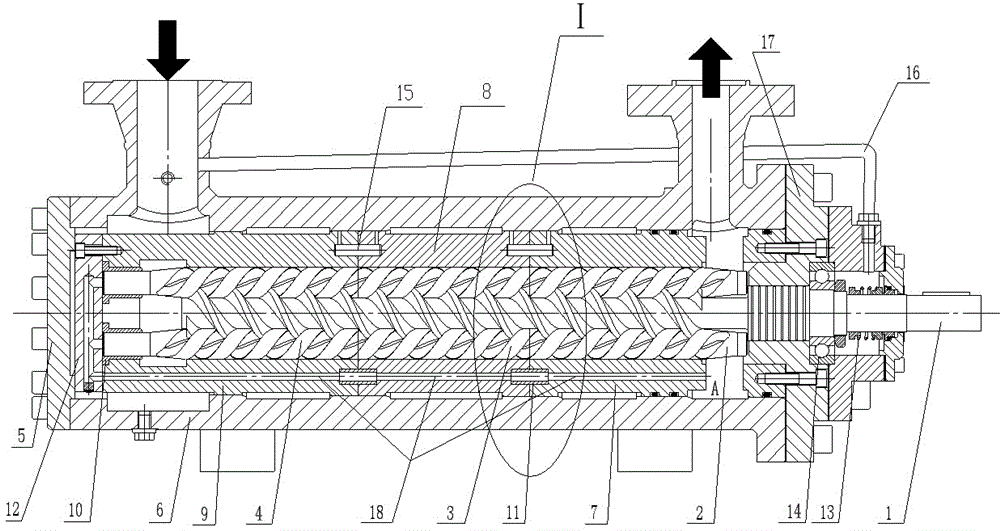

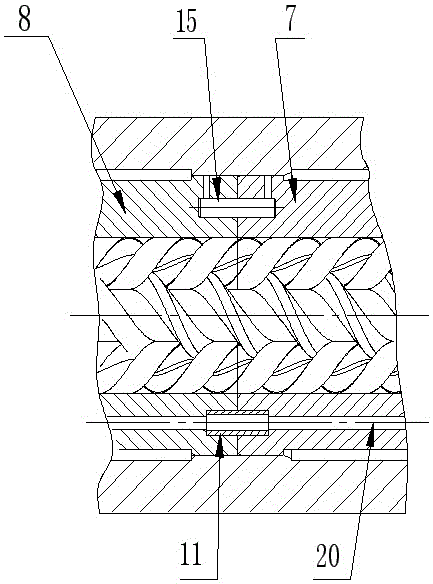

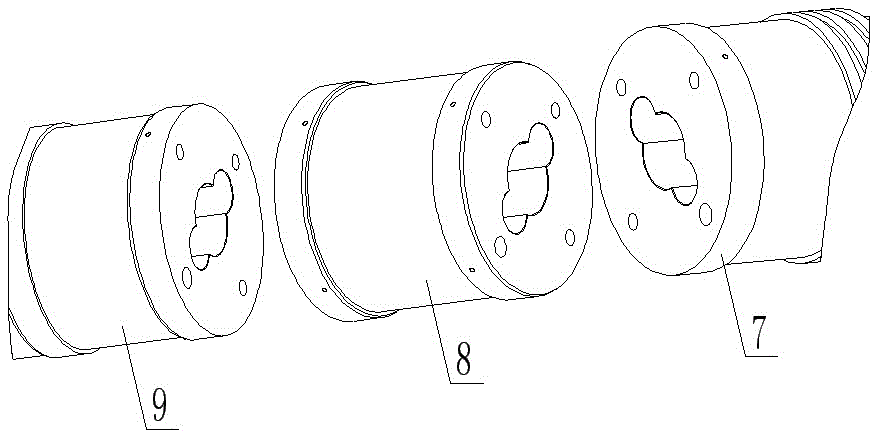

[0020] see figure 1 A high-performance high-pressure three-screw pump includes a pump body 6, a driving screw 1 and two driven screws 19, a bushing 18 is installed axially inside the pump body 6, and the driving screw 1 and two driven screws 19 are co-located on the bushing 18 Inside; the axial ends of the pump body 6 are respectively equipped with a front end cover 17 and a rear end cover 5; the length-to-diameter ratio of the helical section of the driving screw 1 is more than 8, and the driving screw 1 on the side of the driving end is installed on the front end cover through a bearing 14 17, a mechanical seal 13 is installed on the active screw rod 1 in the front end cover 17, and the driving end of the active screw rod 1 extends to the outside of the front end cover 17, and the driving end of the active screw rod 1 in the front end cover 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com