Correction method of linear pressure sensor

A pressure sensor and calibration method technology, applied in the field of calibration, can solve the problems of poor flexibility, large deviation, and large deviation of sampling value of end products, etc., to achieve the effects of compensating for individual differences, reducing production costs, and improving production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

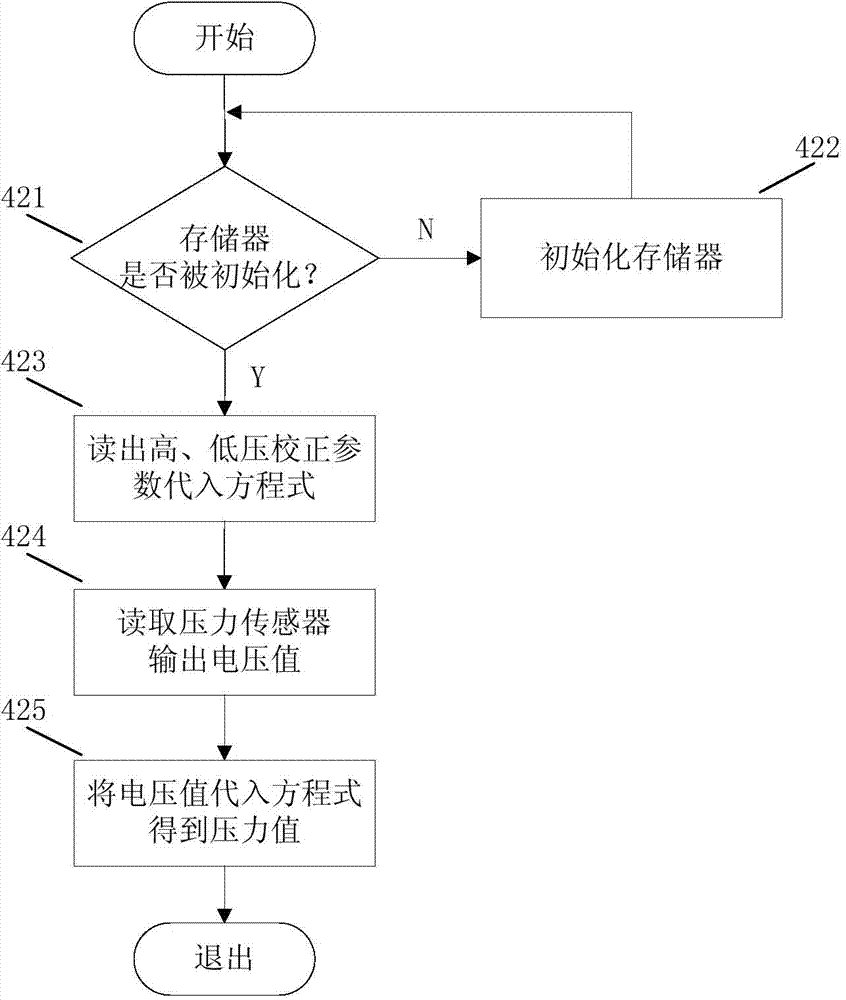

[0027] Taking a pressure sensor with an input pressure range of 0 to 10bar and a proportional voltage output of 0.5 to 4.5V as an example, the input and output equations of the sensor are:

[0028] y=0.4x+0.5y is the output voltage in V; x is the input pressure in bar

[0029] The graph of the input-output equation is as follows Figure 4 shown.

[0030] Adopt the method of the present invention to correct it, comprising the following steps:

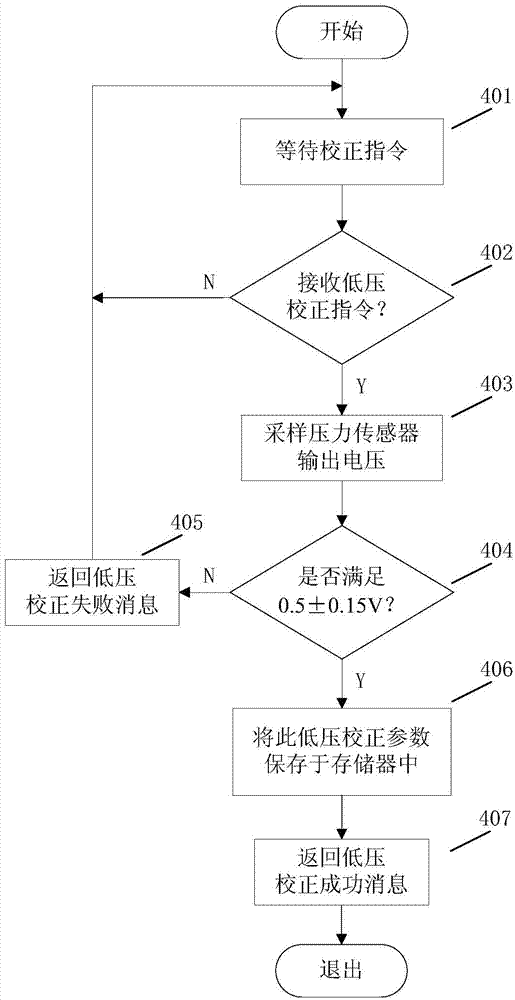

[0031] The first step is to obtain the low pressure calibration parameters, the software process is as follows figure 1 shown, including:

[0032] Before low pressure calibration, the input pressure needs to be adjusted to the standard 0bar.

[0033] In step 401, the terminal product waits for a calibration instruction, and if received, executes step 402.

[0034] In step 402, it is judged whether the correction instruction is a low pressure correction instruction, if yes, enter step 403; otherwise, enter step 401.

[0035] In step...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com