Method for measuring coating thickness of automotive tail gas catalyst

A technology of catalyst coating and automobile exhaust, applied in the direction of measuring device, material analysis by measuring secondary emissions, instruments, etc., can solve problems such as inaccuracy of coating thickness

Active Publication Date: 2014-04-09

昆明贵研催化剂有限责任公司

View PDF5 Cites 11 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The purpose of the present invention is to provide a fast, accurate and simple method for measuring the coating thickness of the automobile exhaust catalyst, and to characterize the coating process of the automobile exhaust catalyst through these indicators, so as to solve the inaccurate measurement of the coating thickness by the existing vernier caliper sex

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

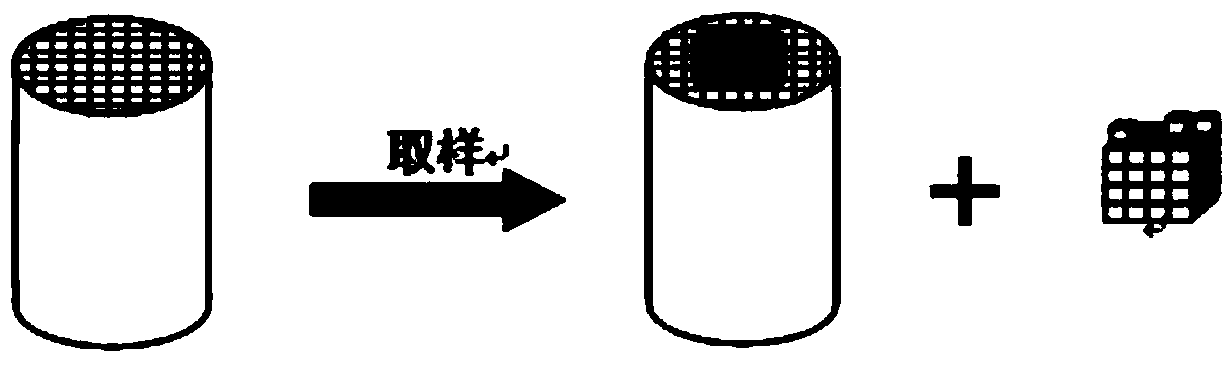

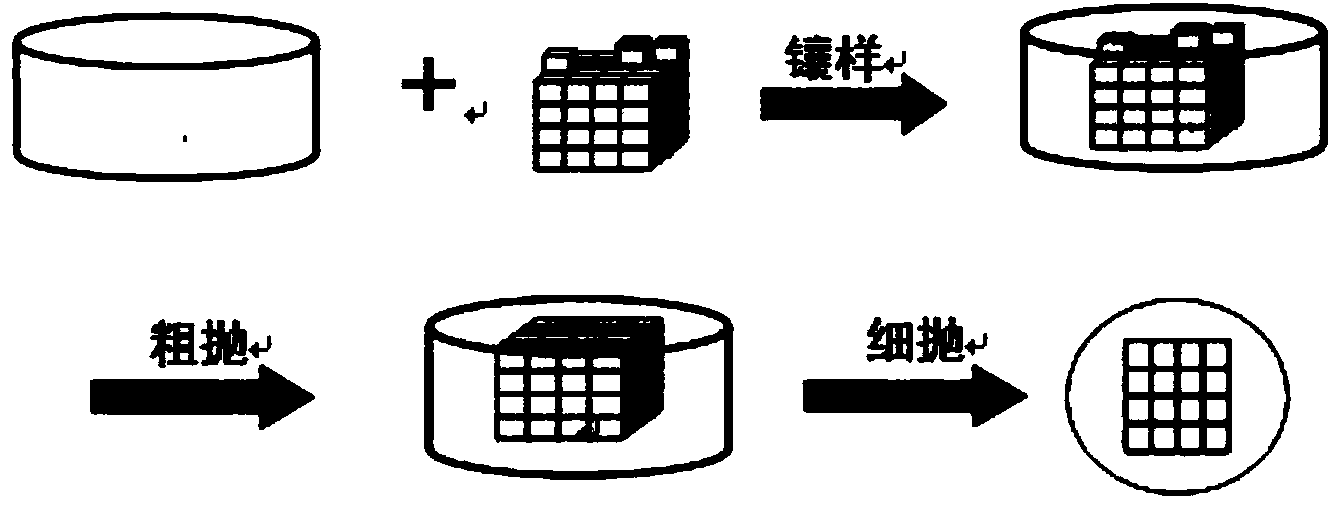

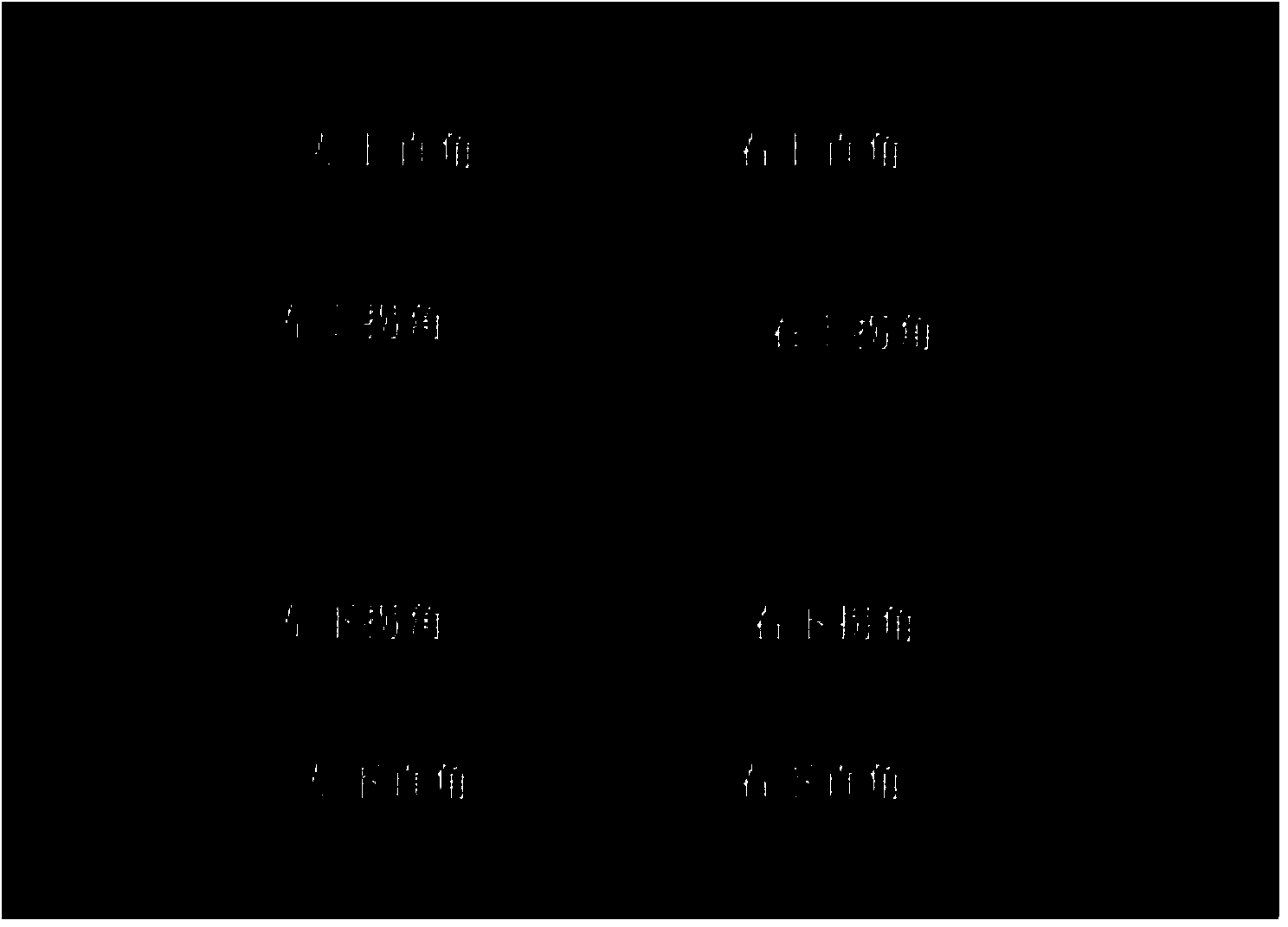

The invention discloses a method for measuring the coating thickness of an automotive tail gas catalyst, and belongs to the field of measurement of physical performance indicators of the catalyst. According to the method, early sample preparation treatment is performed on the automotive tail gas catalyst through a cold pressing mosaic method in a metallographic phase and coating number and coating thickness are directly measured through a scanning electron microscope, and the method has the advantages of being accurate, rapid, visual, simple, convenient and the like, and is capable of solving problems of an existing vernier caliper that the measured thickness is inaccurate and high error is generated. The method for measuring the coating thickness of the catalyst comprises the steps of a. taking a sample; b. implementing metallographic phase preparation treatment on the sample; c. calibrating an instrument; and d. measuring the thickness, wherein the result is accurate to 0.1mm. The method disclosed by the invention can measure the coating thickness of the automotive tail gas catalyst, and also can characterize catalyst coating morphology as well as combination situation of the coating with a carrier.

Description

technical field [0001] The invention relates to a method for measuring the coating thickness of an automobile exhaust catalyst, belonging to the technical field of measuring physical indexes of the automobile exhaust catalyst. Background technique [0002] The coating material is the core material of the automobile exhaust catalyst, which includes the coating substrate alumina; the coating additive zirconia ceria and the active metal platinum palladium rhodium and so on. The loading amount of the coating on the carrier, the bonding strength of the coating and the carrier, the specific surface area of the coating and the microscopic characteristics of the coating will all affect the loading process, loading quality and dispersion state of the active components and additives of the three-way catalyst. It has a great impact, which ultimately affects the activity and service life of the three-way catalyst. Therefore, the measurement of the coating thickness, the bonding stren...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01N23/22G01B15/02

Inventor 卞龙春郑婷婷赵云昆何俊俊夏文正马江丽

Owner 昆明贵研催化剂有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com