Composite material mechanics property evaluation method based on three-dimensional microcosmic crystal whisker composition

A technology for composite materials and whiskers, which is applied in the field of evaluation of mechanical properties of composite materials, and can solve problems such as the inability to realize three-dimensional zinc oxide whisker microscopic modeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

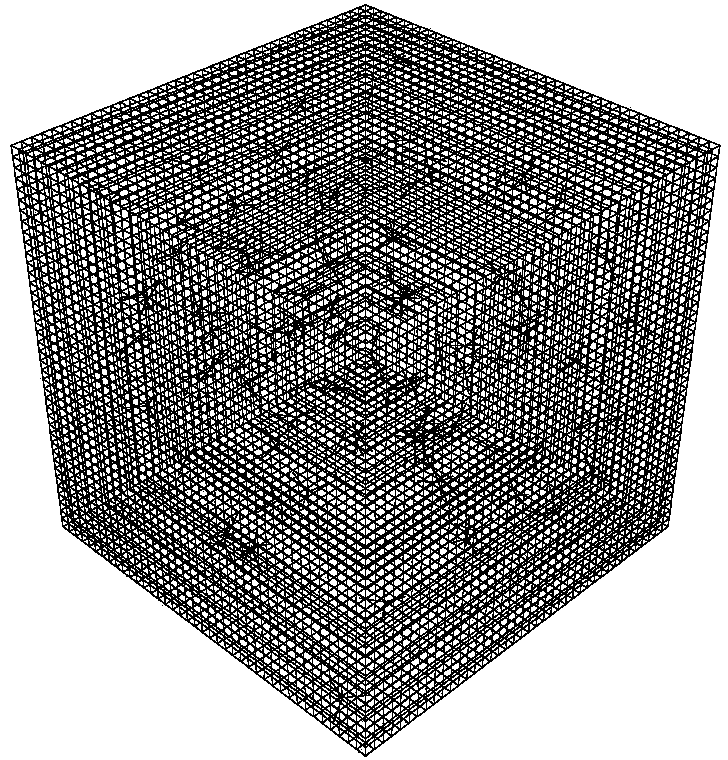

Examples

Embodiment Construction

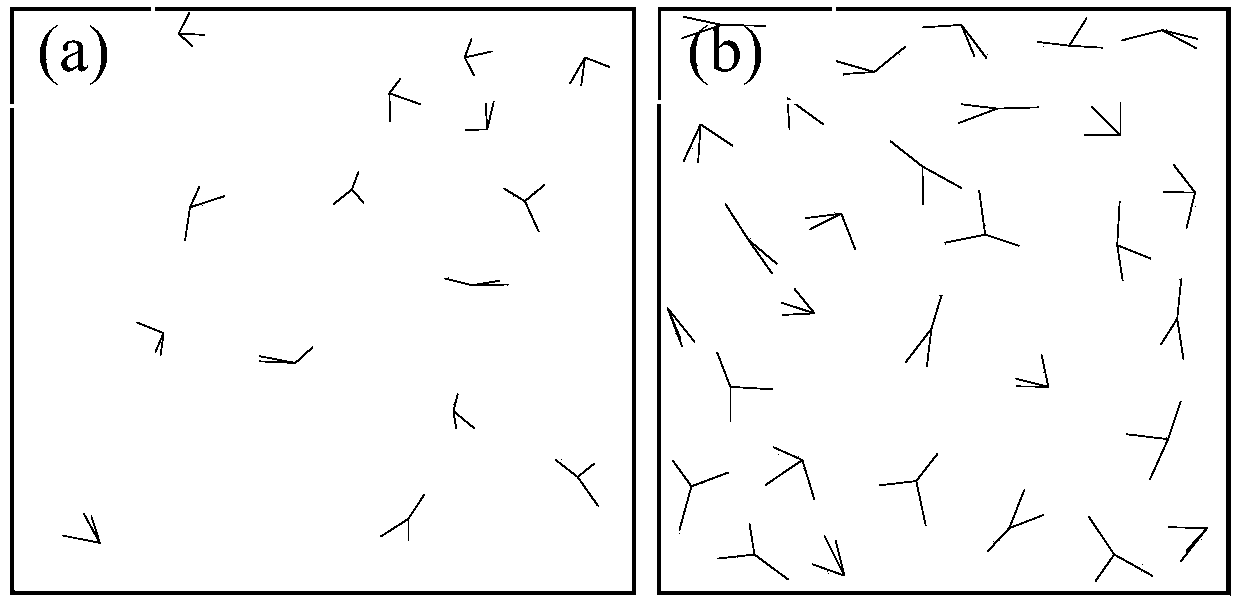

[0032] 1. According to the design requirements, give the length, width and height of the substrate, the length range of whisker stitches (maximum length and minimum length), the number n of whisker stitches and the number m of whiskers. Take the three-dimensional zinc oxide whisker as an example, four pins, n is 4.

[0033] 2. According to the Monte Carlo method, generate (4+6) random numbers, of which 6 random numbers are used as the coordinates of the center point of the whisker and the three Euler angles of the moving coordinate system where the whisker is located.

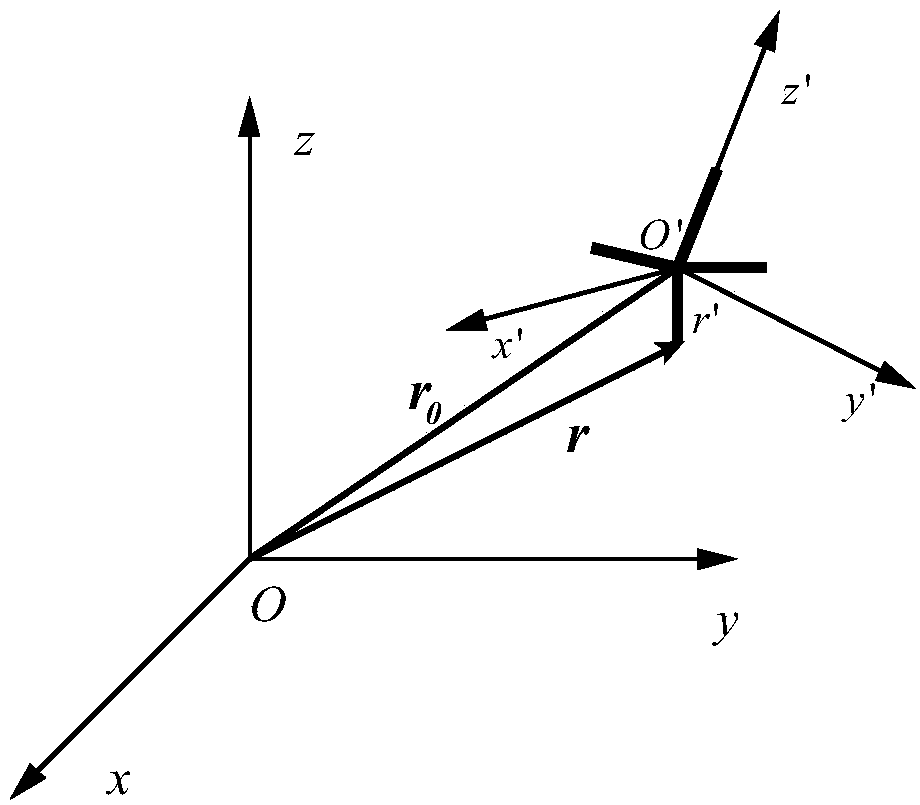

[0034] 3. Use the generated 4 random numbers to multiply the maximum length of the whisker pins to determine the length of the 4 whisker pins; use the generated 3 random numbers to multiply the side length of the substrate, as the origin of the dynamic coordinate system, and also the whisker The coordinates of the central node of . The coordinate system is created as follows:

[0035] Such as image 3 As sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com