Large-stroke two-translation one-rotation precision positioning platform

A technology of precise positioning and moving platform, applied in the micro-nano field, can solve the problems of low axial bearing capacity, small stroke, complex structure, etc., and achieve the effect of simple and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

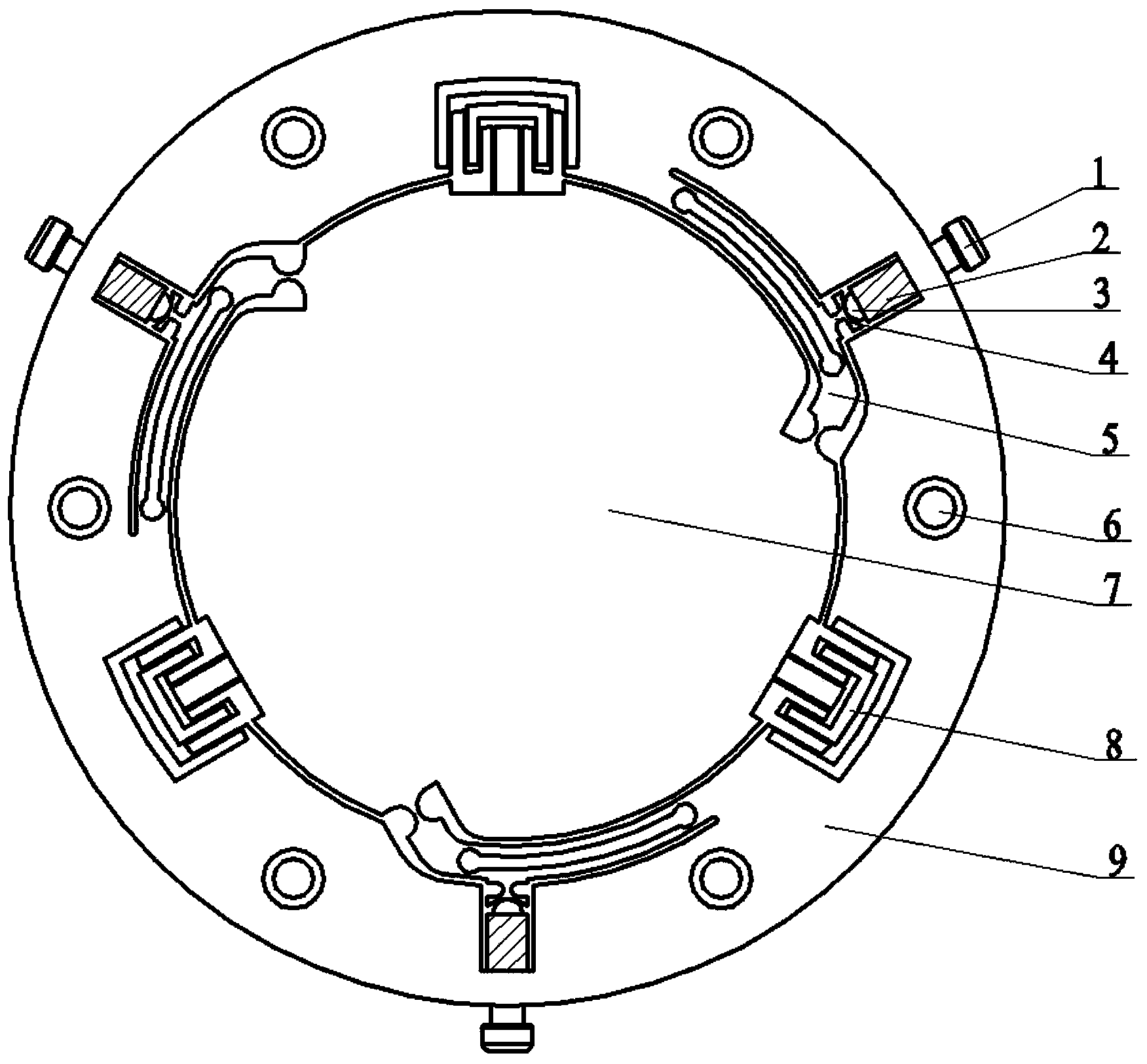

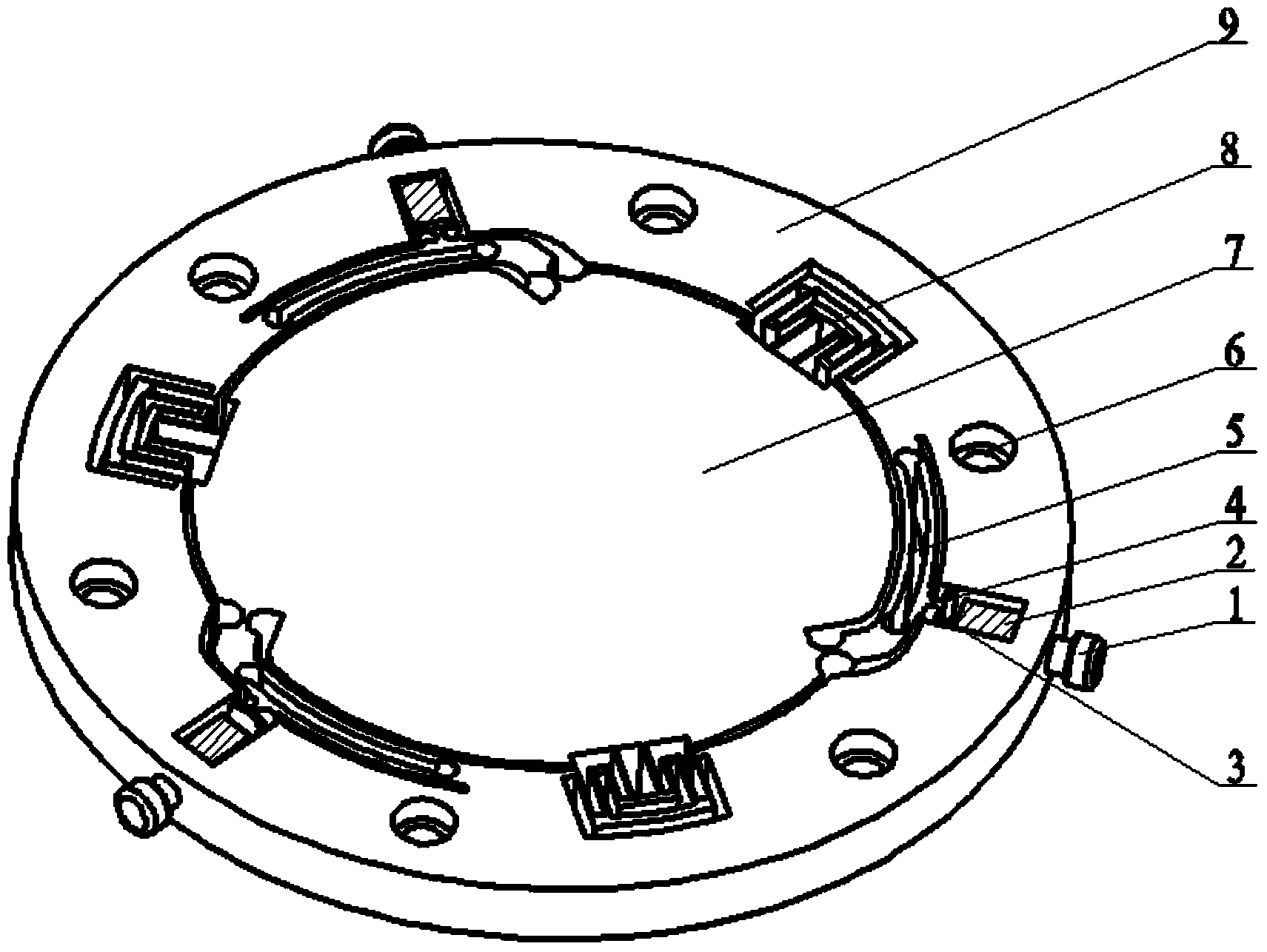

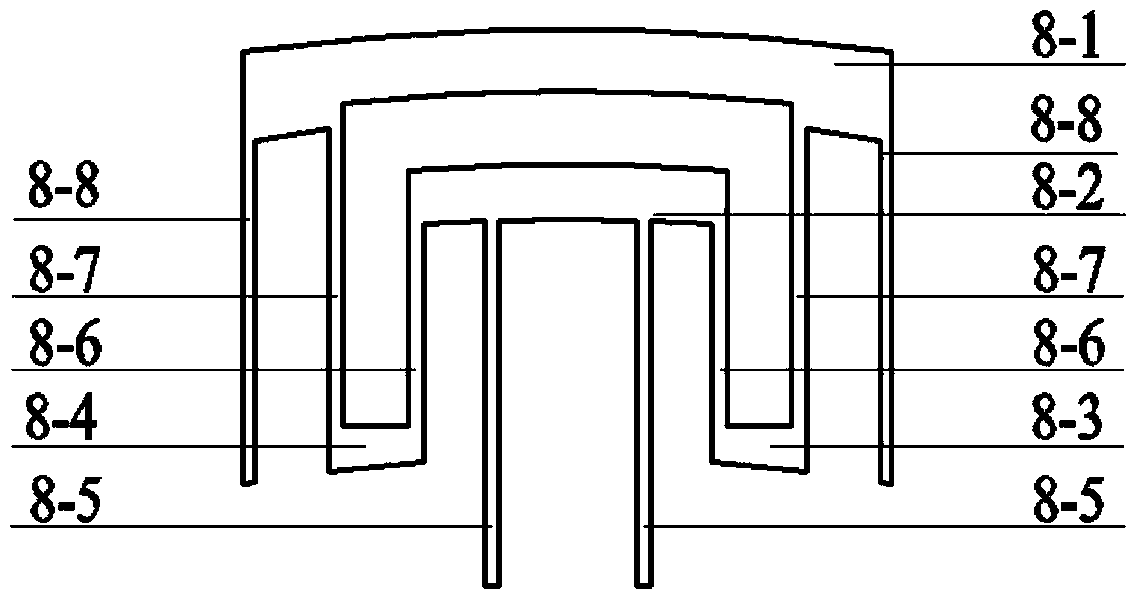

[0014] see Figure 1 ~ Figure 3 , a large-stroke two-translation and one-rotation precision positioning platform, including a base 9 and a moving platform 7 arranged inside it, and the base 9 and the moving platform 7 are distributed uniformly along the circumference of the moving platform through three The hinge amplifying mechanism 5 is connected with three composite parallel plate flexible guide mechanisms 8.

[0015] One end of each hinge amplifying mechanism 5 is flexibly connected to the base 5, the other end is flexibly connected to the moving platform 7, and an input end is provided in the middle, and the input end of the hinge amplifying mechanism is connected through a flexible hinge 4 and a ball joint. 3 is connected to the piezoe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com