Formation process for electrode plate of lead-acid storage battery

A lead-acid battery and process technology, which is applied to lead-acid battery electrodes, secondary battery charging/discharging, and secondary battery repair/maintenance, etc., can solve problems such as increased acid treatment costs, increase hydration steps, and reduce costs. , the effect of extending battery life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

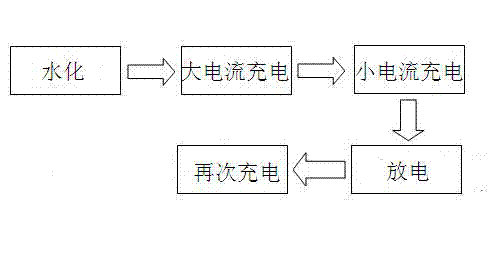

[0010] Such as figure 1 As shown in the flow chart of the present invention, the steps included in the formation process of the present invention include: first hydrating the plate: the thickness of the grid in this embodiment is a medium thickness, and the hydration is 60 minutes. The thickness of the grid should be properly adjusted, the hydration time of the thinner grid is shorter, and the hydration time of the thicker grid is longer. After testing, the best hydration time is 60 minutes, and grids of various specifications can adapt to this Hydration time; high current charging after hydration: This step is carried out after hydration and before the grid loses water, and the current density used is 11.5mA / m 2 , to the end of the tank voltage 2.37V; then charge with a small current, the current density is 7.5 mA / m 2 , to 100% of the theoretical capacity; after the small current charging is completed, the discharge step is carried out to the cell voltage of 1.77V; rechargi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com