Air cooling heat dissipation mechanism for wheel hub motor of electromobile

A technology of in-wheel motor and heat dissipation mechanism, which is applied to electric vehicles, motors, electric components, etc., can solve the problems of high temperature and cannot operate normally, and achieve the effect of simple structure, convenient processing, and increased heat dissipation area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with accompanying drawing, the present invention is described in further detail:

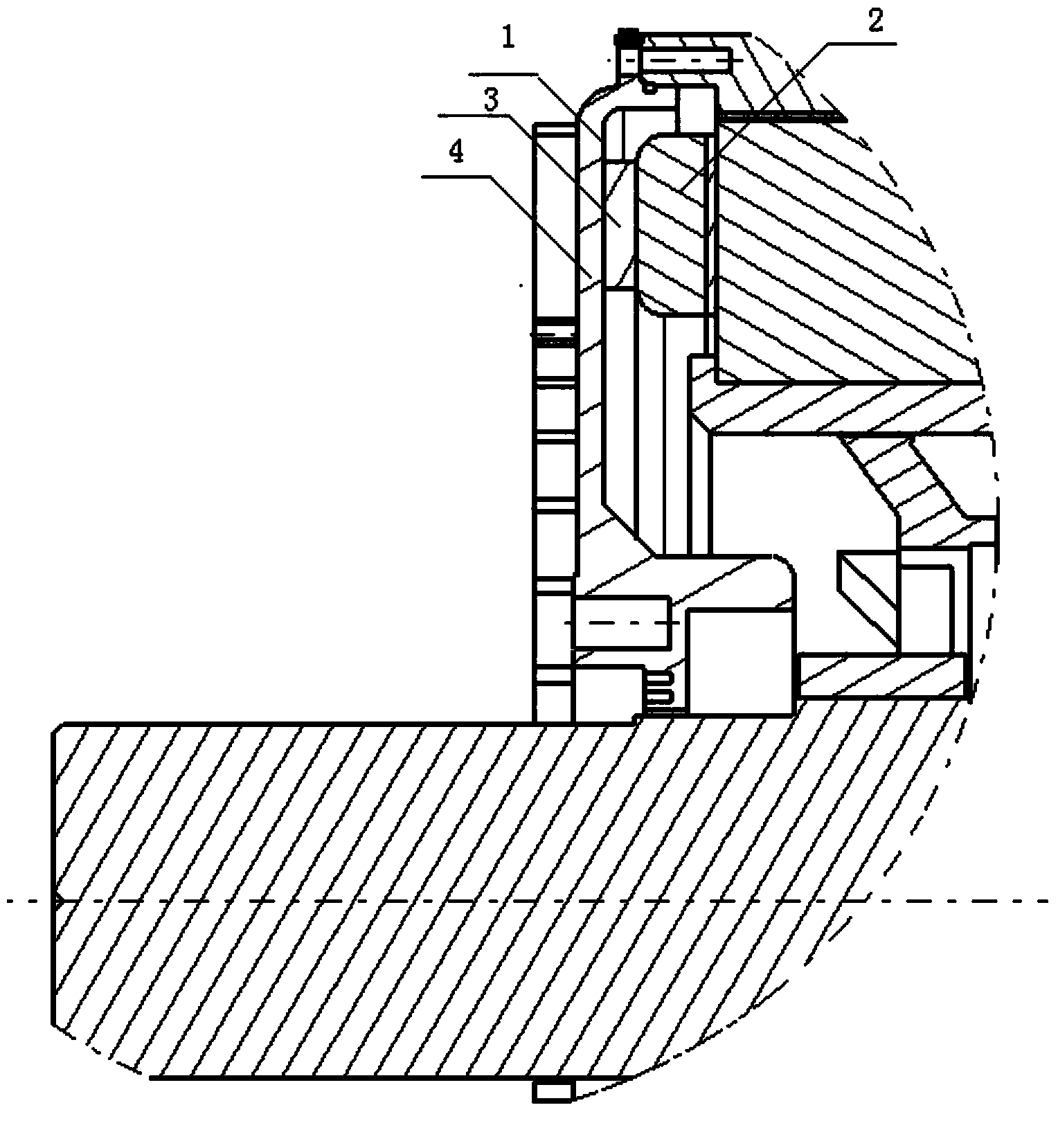

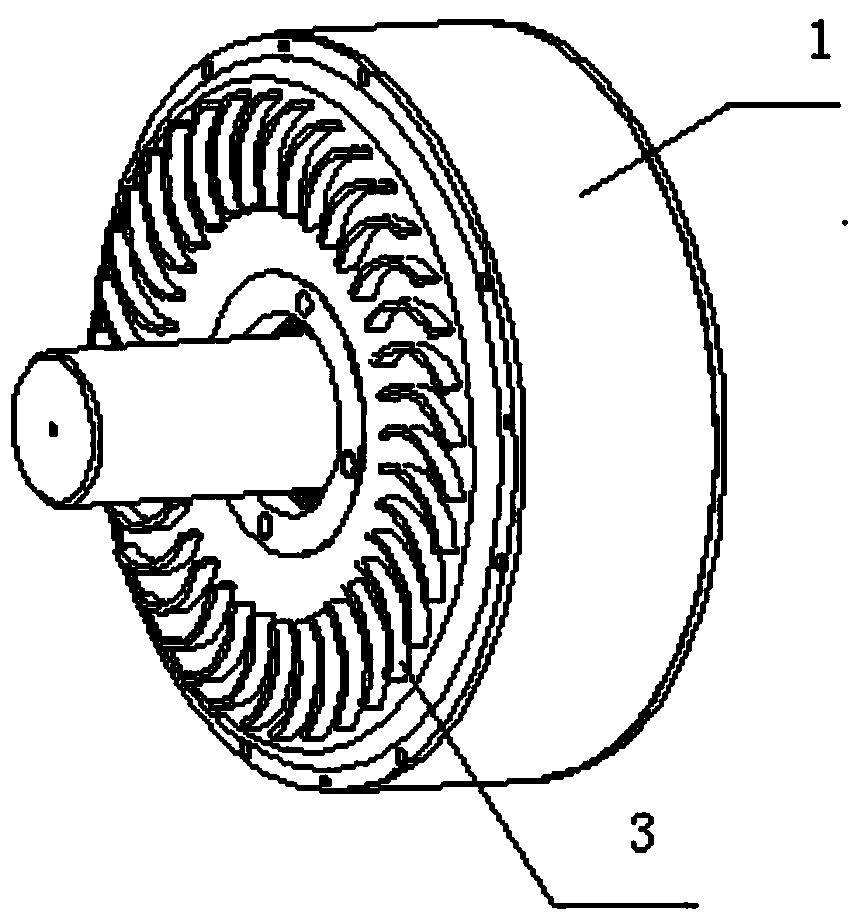

[0019] Such as figure 1 ,Such as figure 2 As shown, the present invention provides an air-cooled and heat-dissipating mechanism for a hub motor of an electric vehicle, comprising a hub motor housing 1 and a motor winding 2. Outer raised blades3. Considering that the work of the automobile hub motor is mainly carried out through the motor winding, the motor winding will generate a lot of heat. If the blades are set relative to the motor winding, the best heat dissipation effect can be achieved. The blades 3 are arc-shaped. The angle of the air outlet of the blade is less than 90 degrees. The distance between each blade 3 is 20mm-80mm. The thickness and quantity of the blades 3 should be calculated and determined according to the heat dissipation of the hub motor. The thickness of the blades selected by the present invention is in the range of 3 mm to 5 mm. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com