Brushless direct current motor rotor position detecting device and phase changing method

A technology of rotor position detection and brushed DC motor, which is applied in the direction of electronic commutator, etc., can solve the problems of difficult implementation and complicated hardware circuit, and achieve the effects of simplified acquisition, smooth operation and speed regulation, and accurate commutation operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0030] The motor used in the implementation example is a compressor motor used in a DC inverter air conditioner, and its parameters are as follows:

[0031] (1) Motor type: brushless DC motor (BLDCM);

[0032] (2) Number of pole pairs: p=2;

[0033] (3) Rated speed: n=3600rpm;

[0034] (4) Rated output power: W = 650W;

[0035] (5) Winding resistance of each phase: r=0.9Ω (20°C);

[0036] (6) Winding inductance per phase: L σ = 3.35mH;

[0037] (7) Working frequency: f=20~190Hz;

[0038] (8) Moment of inertia of rotor: J=6.55×10 -4 (Kg m 2 );

[0039] (9) Potential coefficient Ke=13.2 (mV / rpm);

[0040] (10) Torque coefficient K T = 0.392 (N·m / A).

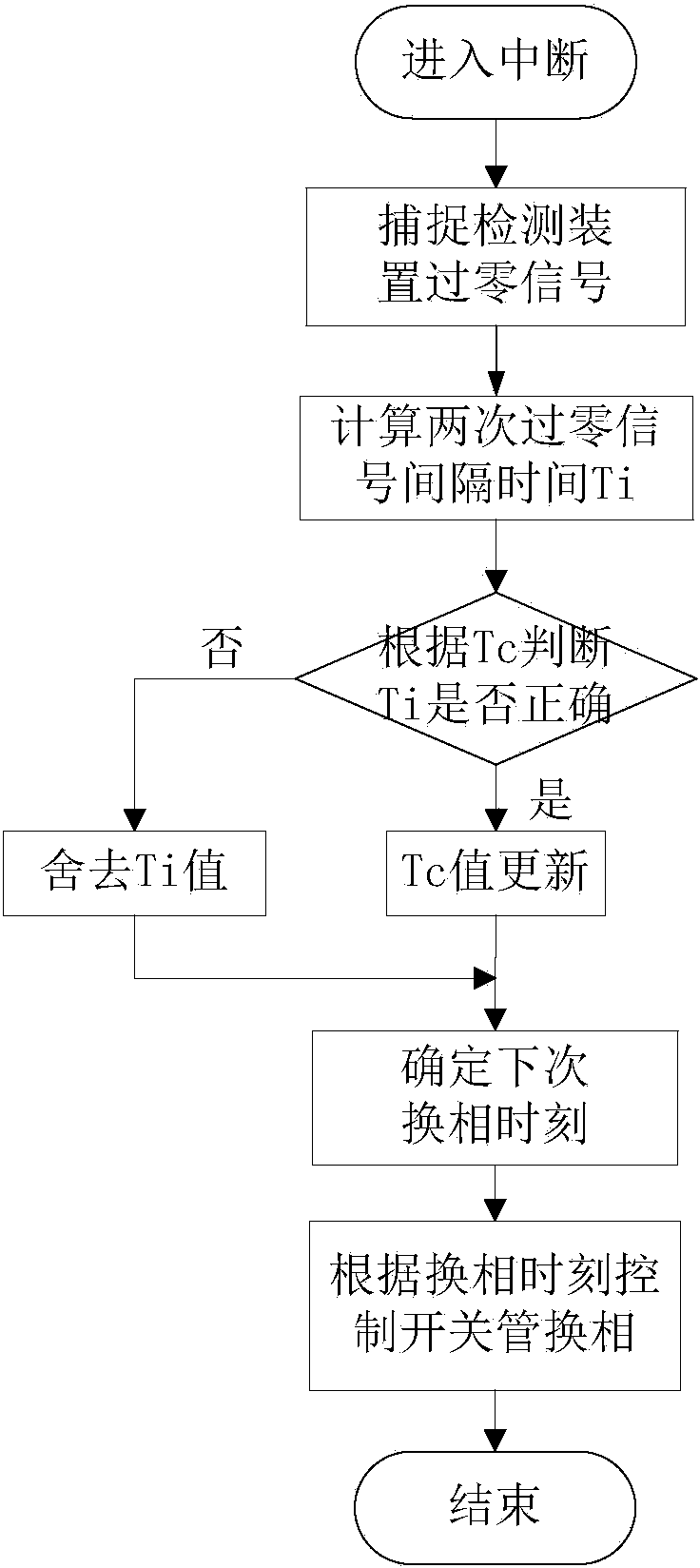

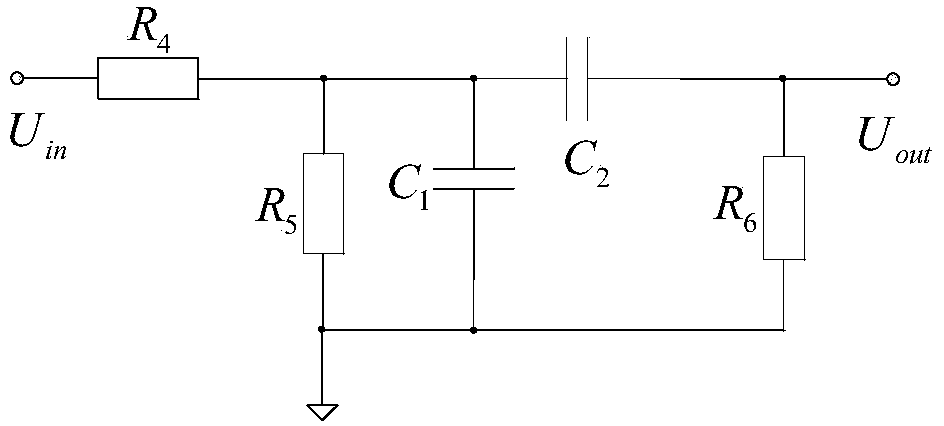

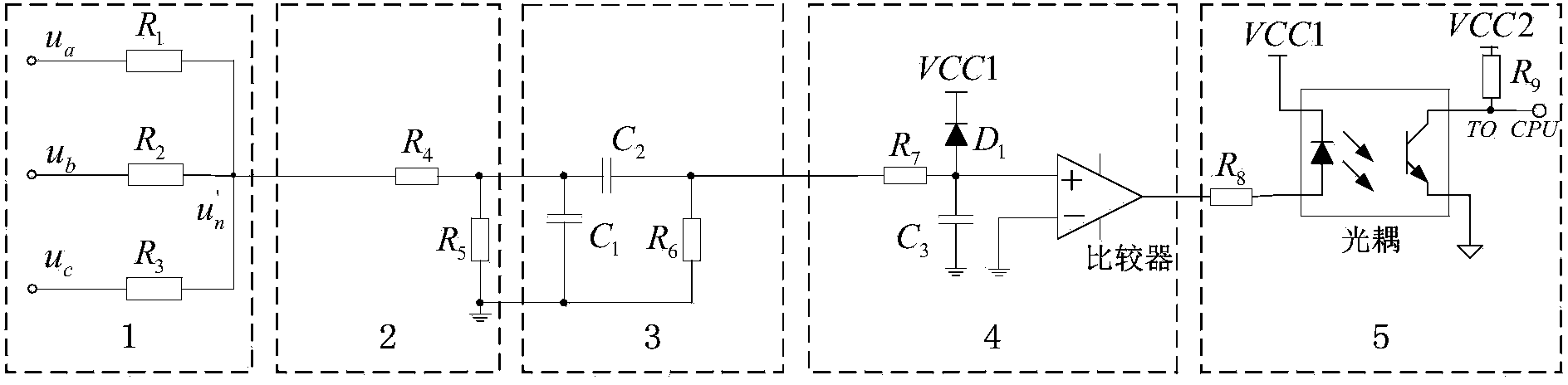

[0041] The Y-type network input terminal of the brushless DC motor position detection device is connected to the three-phase terminal voltage of the motor, and the obtained simulated neutral point voltage is divided by a resistor through a voltage dividing circuit, and the third harmonic of the counter electromotive forc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com