System for electrically heating and stirring pasted agent

A stirring system and electric heating technology, applied in mixer accessories, mixers with rotary stirring devices, dissolving and other directions, can solve the problems of inability to measure, occupy a large area, and a large amount of hot water, and achieve the effect of reasonable configuration and investment saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

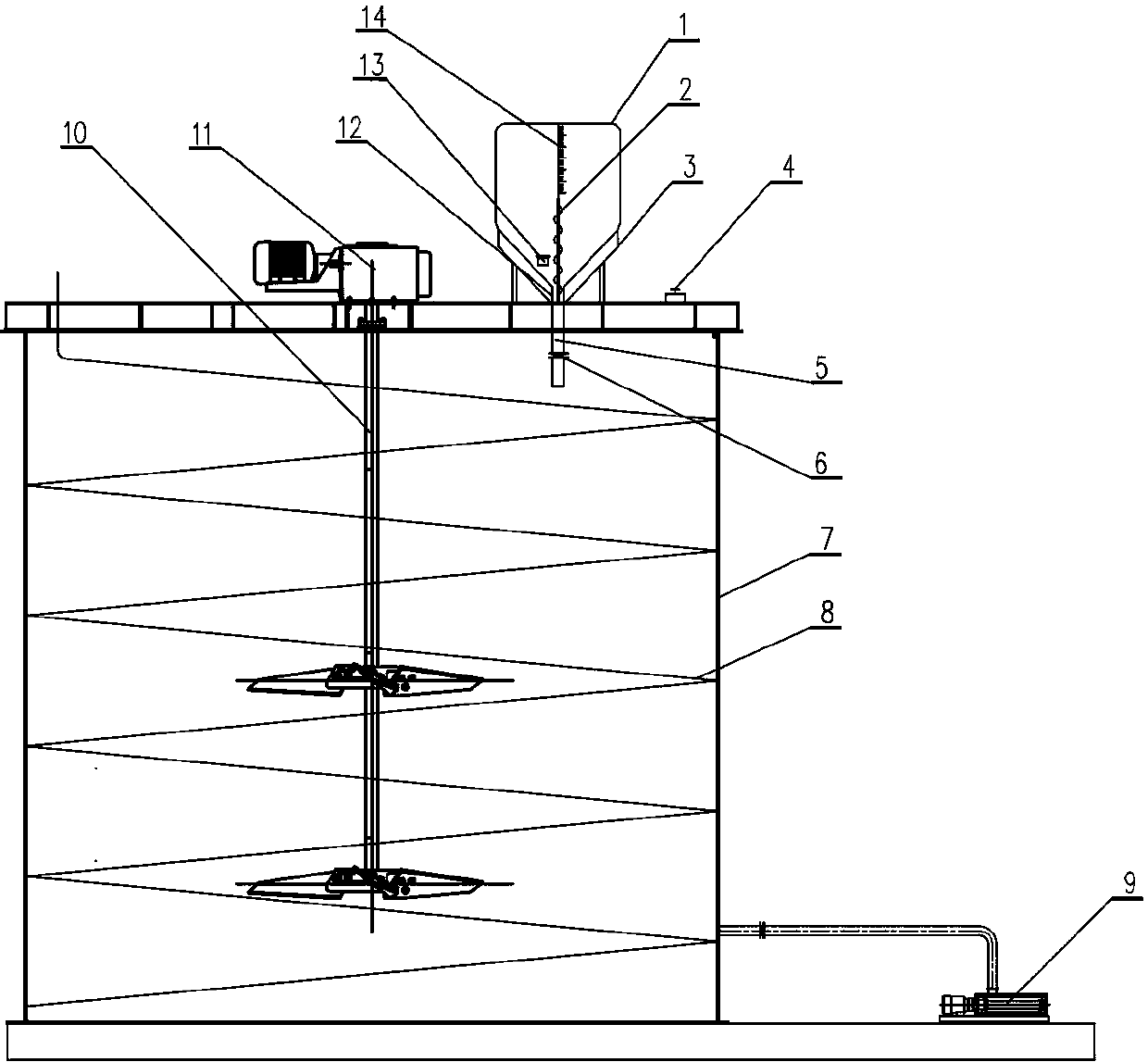

[0015] The specific implementation manner of the present invention will be further described below in conjunction with the accompanying drawings.

[0016] Such as figure 1 As shown, a paste-shaped medicament electric heating and medicament stirring system of the present invention includes a medicament electric heating device and a medicament stirring device. The ejector rod type resistance heater 2 in 1 is made up of, and described medicament agitating device is by medicament stirring tank 7, and the feeding hopper 3 that is welded on the top of medicament stirring tank 7, is connected to the outside of the bottom of medicament stirring tank 7 with pipelines. The medicine delivery pump 9, the motor and the reducer 11 arranged on the upper part of the medicine stirring tank 7, the stirring device 10 connected with the motor and the reducer 11, and the helical steam pipe 8 arranged on the inner side of the medicine stirring tank and connected by bolts ,

[0017] The dosing bar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com