A glass lubricant coating device for high-temperature blanks in hot extrusion process

A technology of glass lubricant and coating device, which is applied in the field of glass lubricant spraying device and glass lubricant coating device, which can solve the problems of uneven spraying of glass lubricant, overheating of roller brush, labor and time-consuming, etc., and achieve relief Effects of workload reduction, manpower reduction, and improvement of loading efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

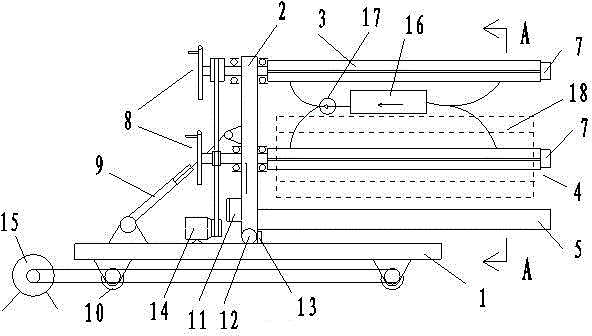

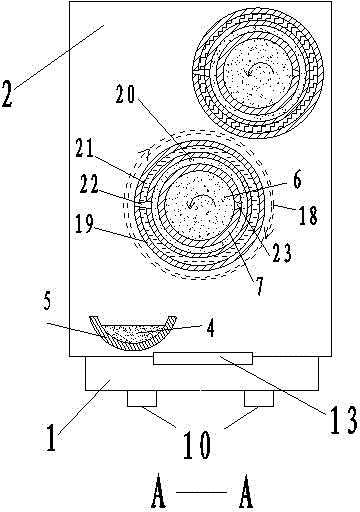

[0017] see figure 1 and figure 2 , the present invention includes a frame, a washing mechanism and a water circulation mechanism; the washing mechanism includes an inner wall washing roller 4, an outer wall washing roller 3 and a rotating handle 8; 2, the inner wall washing roller 4 and the outer wall washing roller 3 are the same sleeve structure, and the inner tubes of the sleeve are successively a charging chamber, a buffer chamber and a cooling chamber from the inside to the outside; A discharge port is provided between the tubes; a rotating handle 8 is provided at one end of the inner wall washing roller 4 and the outer wall washing roller 3 . The wall of the first tube is provided with a first discharge port 23, the wall of the second tube is provided with a second discharge port 22, and the second discharge port 22 is connected with the third tube. The opening of the cylinder wall of the cylinder 19 is connected; the first discharge port 23 is opposite to the second ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com