Side casting system

A casting system and side casting technology, applied in the directions of casting molds, casting mold components, casting molding equipment, etc., can solve the problems of easy splashing of the casting liquid and the generation of cold isolation, and achieve the effect of avoiding splashing and cold isolation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

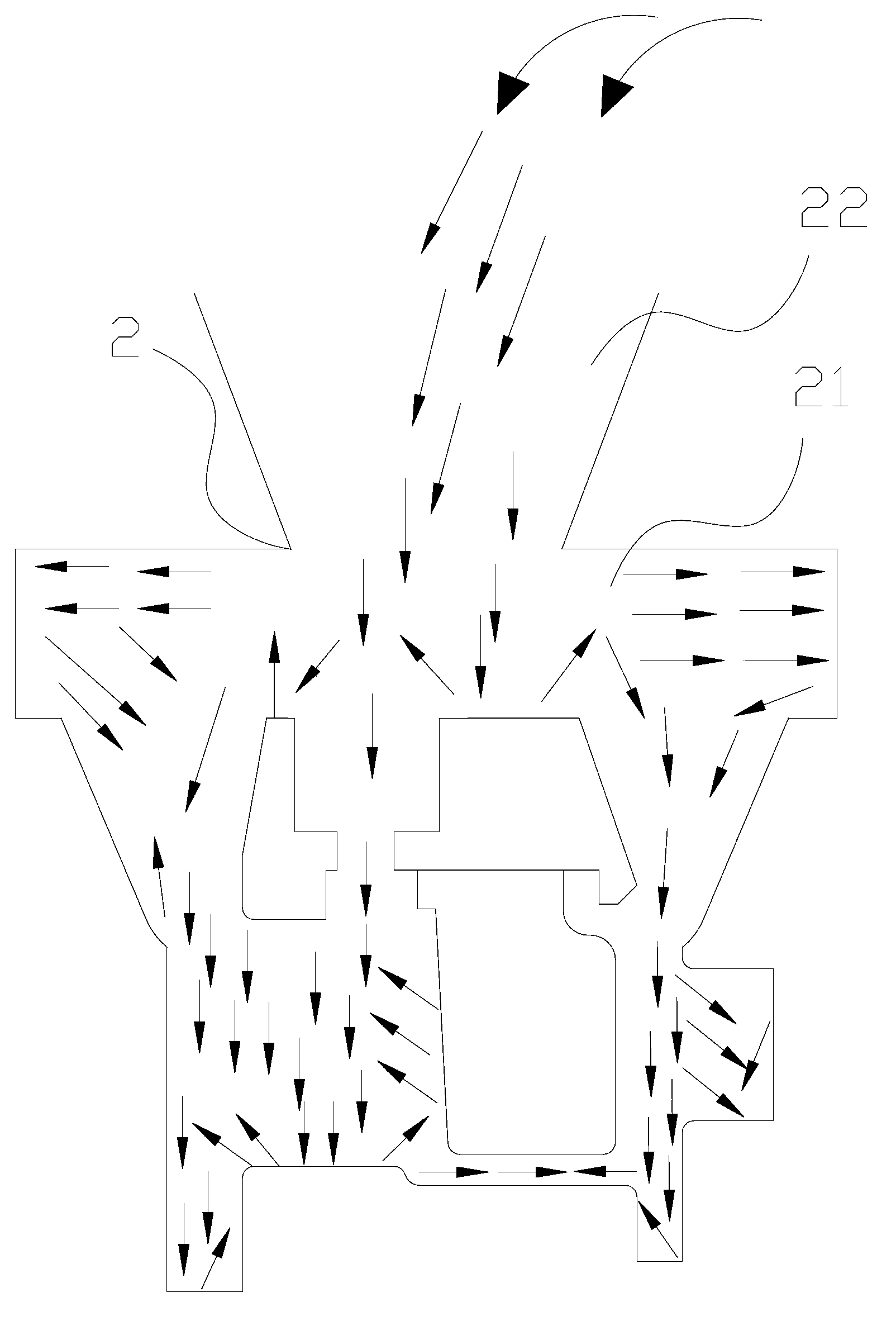

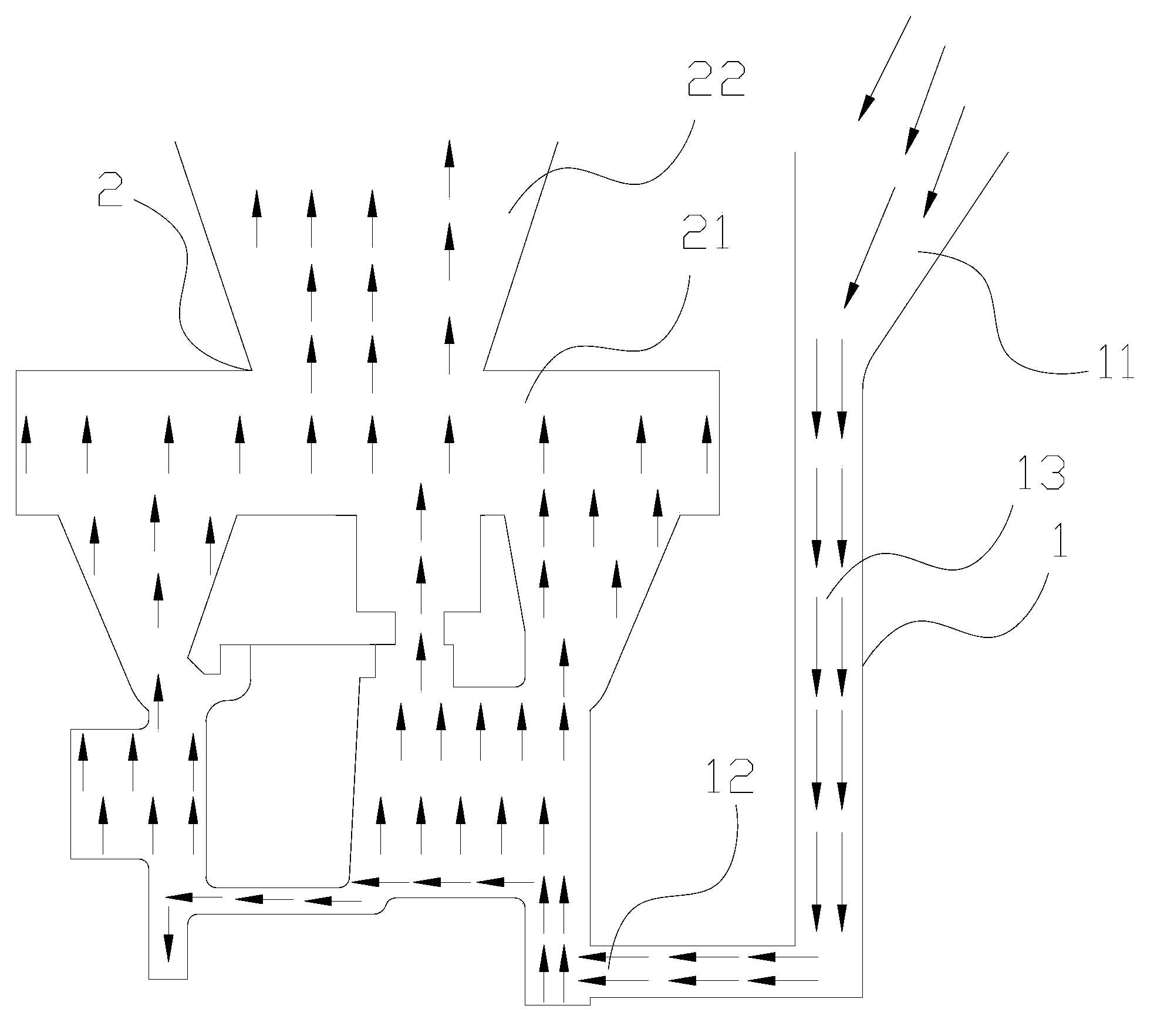

[0019] Such as figure 2 , the side casting casting system of the present embodiment includes a mold shell body 2, the inside of the mold shell body 2 is a cavity including a casting forming part 21 and a riser part 22, and the side casting device 1 is connected to the mold shell body 2 There is a channel 13 inside the side casting device 1 under the side. One end of the channel 13 is an external gate 11 leading to the outside world, and the other end is a feed port 12 leading to the cavity. Specifically, the side casting device 1 is connected to the bottom end of the side of the formwork body 2, so as to ensure that the casting liquid (hereinafter, molten steel is used as an example) can gradually flow upward from the lowest point, even if it hits the mold In the case of complex shell shape, the flow direction of the molten steel is always upward, and there will be no flow in other directions. The details are as follows: figure 2 The arrows in are all pointing upwards. Of ...

Embodiment 2

[0025] The difference between this embodiment and Embodiment 1 is that the side casting device 1 is connected to the lower middle position of the formwork body 2, which can also solve the problems of splashing of casting liquid and cold insulation. Other parts of this embodiment are the same as those of Embodiment 2, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com