Bucket tooling

A bucket and tooling technology, applied in auxiliary devices, manufacturing tools, metal processing equipment, etc., can solve the problem that the bucket is difficult to meet the requirements, and achieve the effects of low cost, simple structure, and easy assembly and disassembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

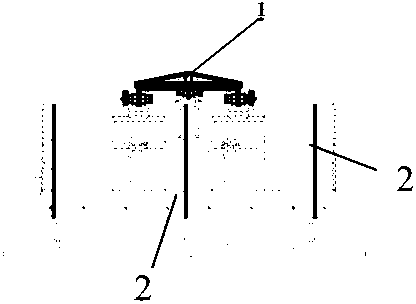

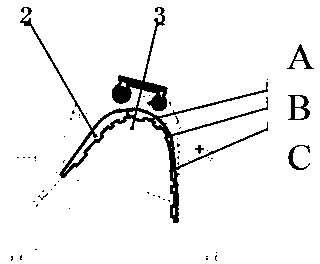

[0015] The invention is used for splicing and welding of loader buckets. The tooling is mainly composed of 3 major modules: 1. Support plate limit assembly; 2. Bucket wall plate limit component, 3. Original bucket bucket serialized bucket tooling.

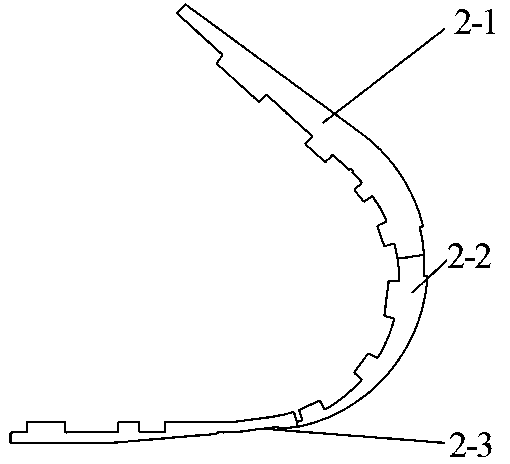

[0016] Such as figure 1 , 2 , 3, the bucket wall plate limit assembly 2 includes the first bucket wall plate 2-1, the second bucket wall plate 2-2, the third bucket wall plate 2- 3. The bucket wall plate limit assembly 2 is connected with the mother bucket assembly tooling by spot welding.

[0017] The bracket of the support plate limit assembly includes a limit sleeve corresponding to the number of bucket group holes, each of which has a pin extending into the bucket hole; as image 3 , 5 The three groups of hole support plate limit assemblies 2 shown have three sets of limit sleeves 4, wherein two sets of limit sleeves have pins 5 extending into the bucket holes.

[0018] Such as Image 6 , 7 In the shown structure, the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com