Welding jig for elevator lift car bracket

A technology for elevator cars and welding fixtures, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve problems such as low operating efficiency, high requirements for welding positioning, and difficulty in ensuring welding quality, so as to improve production Efficiency, guaranteed welding quality, and the effect of meeting process requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

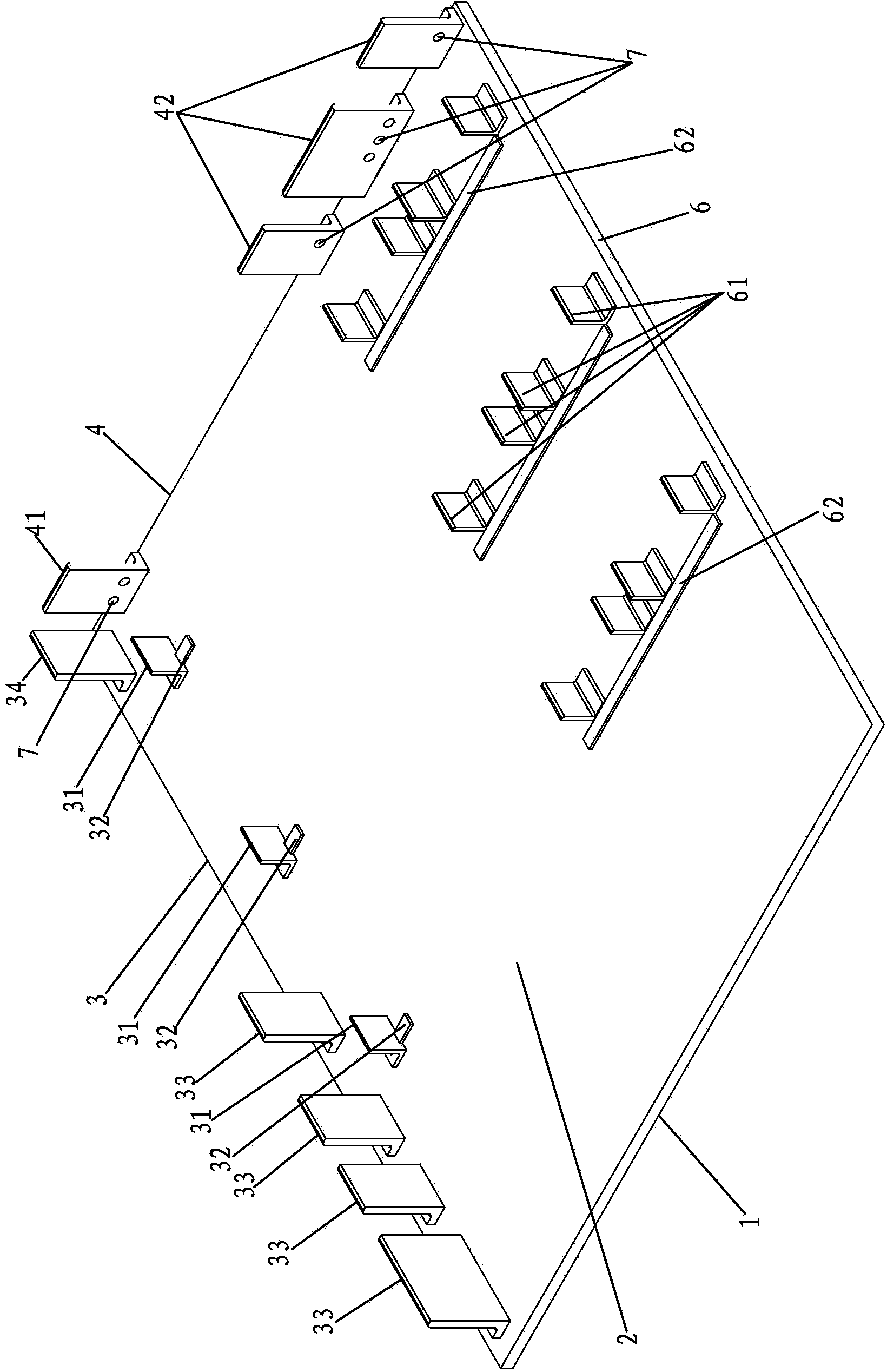

[0017] An embodiment of a welding jig for an elevator car bracket according to the present invention will be described in detail below in conjunction with the accompanying drawings.

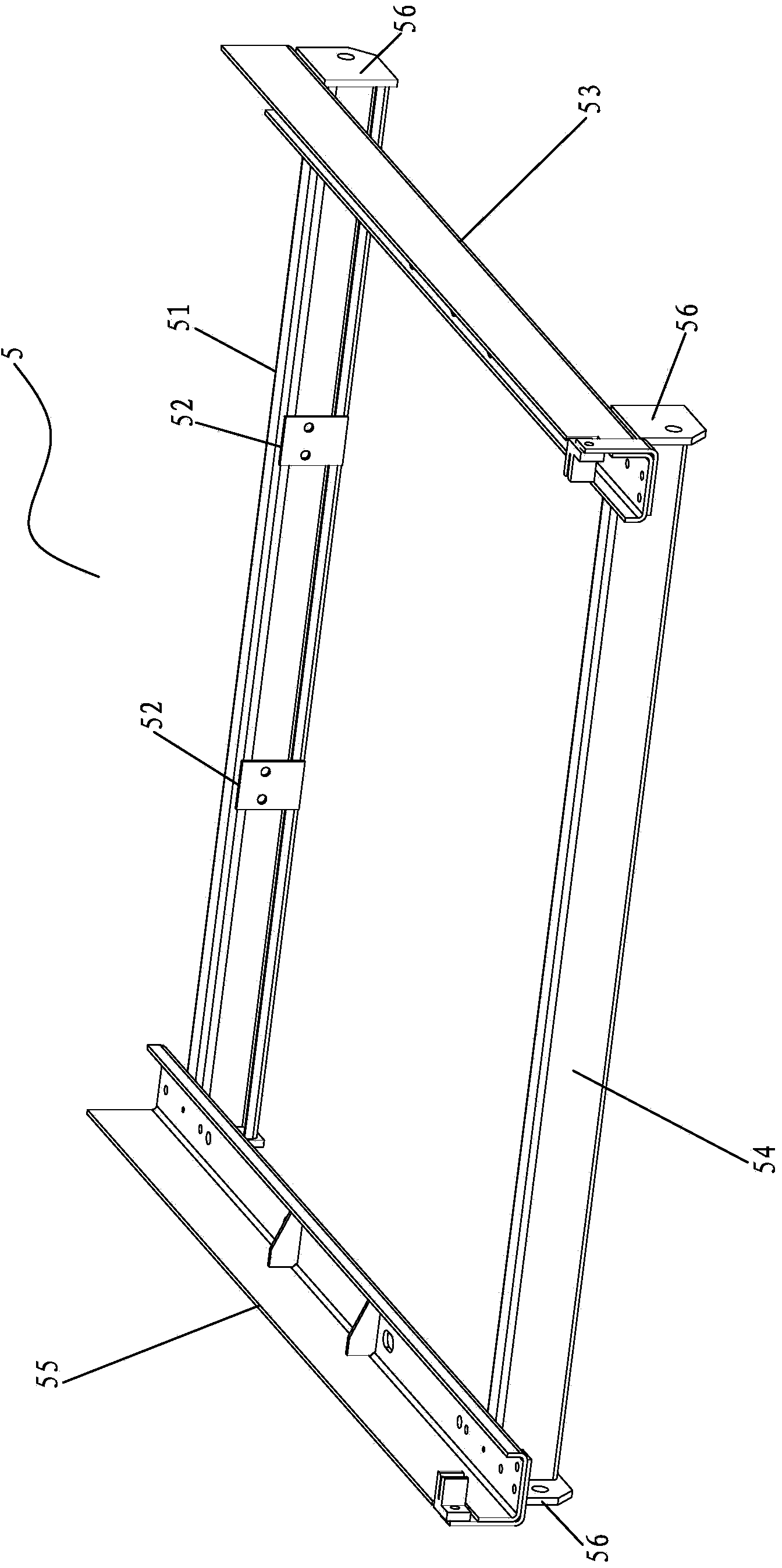

[0018] A welding jig for an elevator car bracket according to the present invention comprises a welding pallet 1. The welding pallet 1 includes a positioning reference plane 2 for positioning welding. The positioning reference plane 2 is provided with a first positioning edge 3, The second positioning edge 4 vertically intersecting with the first positioning edge 3 and the third positioning edge 6 vertically intersecting with the other end of the second positioning edge 4, the inside of the first positioning edge 3 is provided with several pieces for the elevator car bracket 5 The front beam side positioning block 31 positioned on the outer side of the front beam 51 and the connecting plate positioning block 32 for positioning the connecting plate 52 welded on the inner side of the front beam 51, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com