Device integrating solid crushing and coarse and fine gratings

A technology of crushing device and coarse grid, which is applied in chemical instruments and methods, water/sewage multi-stage treatment, grain treatment, etc., can solve the problems of high cost, large area occupation, large energy consumption, etc., and achieve convenient management and structural Novelty, small footprint effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be described in detail below with the best embodiment.

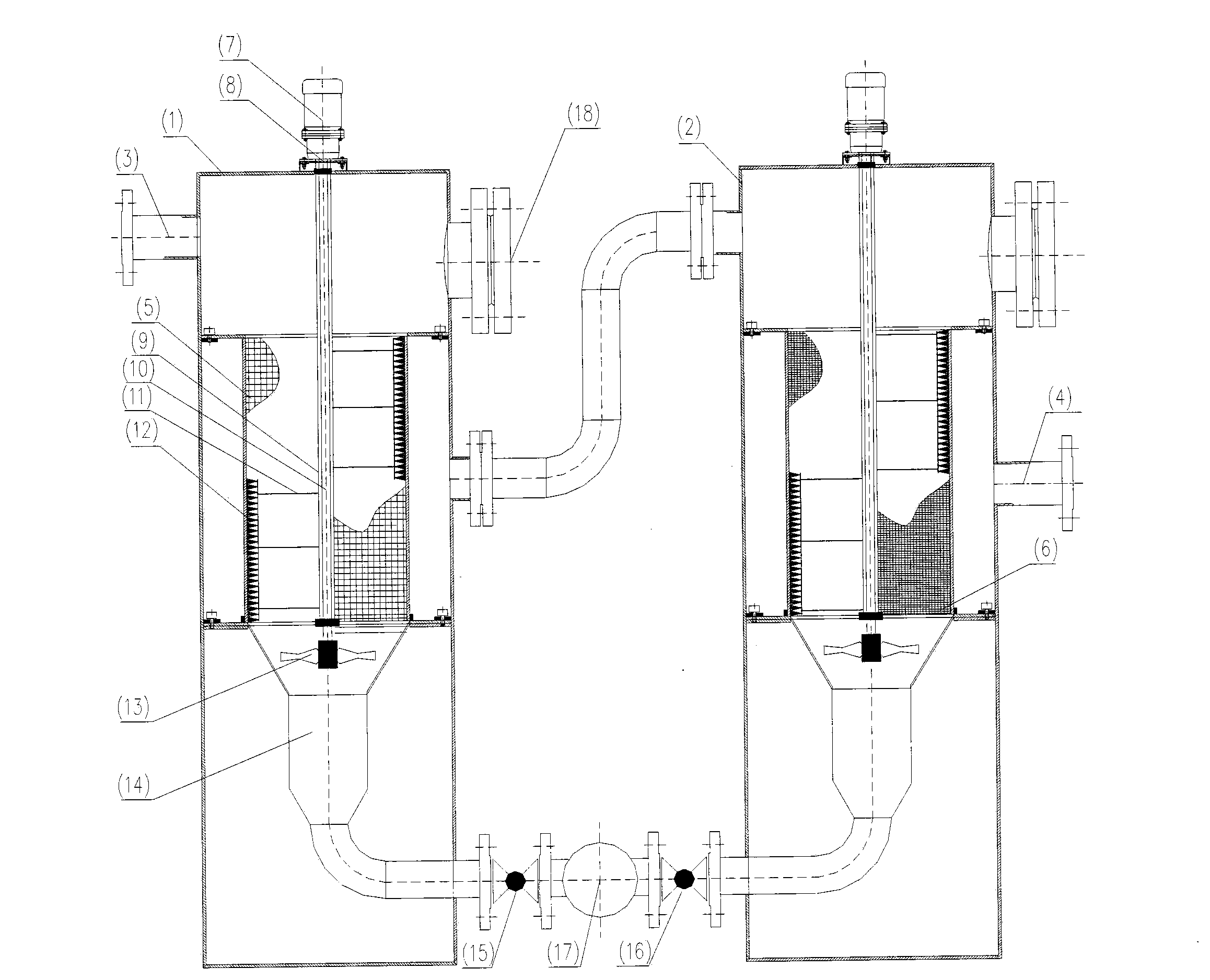

[0010] like figure 1 The shown integrated device for solid crushing and coarse and fine grids includes coarse grids and crushing devices (1), fine grids and crushing devices (2), water inlets (3), water outlets (4), coarse grids ( 5), fine grid (6), motor (7), gearbox (8), rotary brush shaft (9), reamer shaft (10), rotary brush bracket (11), rotary brush (12), reamer (13), slag storage chamber (14), coarse screen and crushing device slag discharge valve (15), fine screen and crushing device slag discharge valve (16), slag discharge supervisor (17), maintenance manhole (18) And the corresponding water baffles, deflectors, brackets and pipe fittings, etc.

[0011] The coarse grid and crushing device (1) is provided with a coarse grid (5), the spacing of the grid bars is 1 mm to 50 mm, and the cross section of the grid bars is circular, polygonal or irregular; the coarse grid and the crus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com