A method for splitting thymosin β4

A technology of thymosin and lysate, which is applied in the field of peptide cleavage, can solve the problems of large amount of reagents used, environmental pollution, unsuitable for thymosin β4, etc., and achieves the effect of facilitating industrial production, reducing production costs, and improving the purity of crude peptides

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] Thymosin β4 peptide resin was obtained by solid phase synthesis.

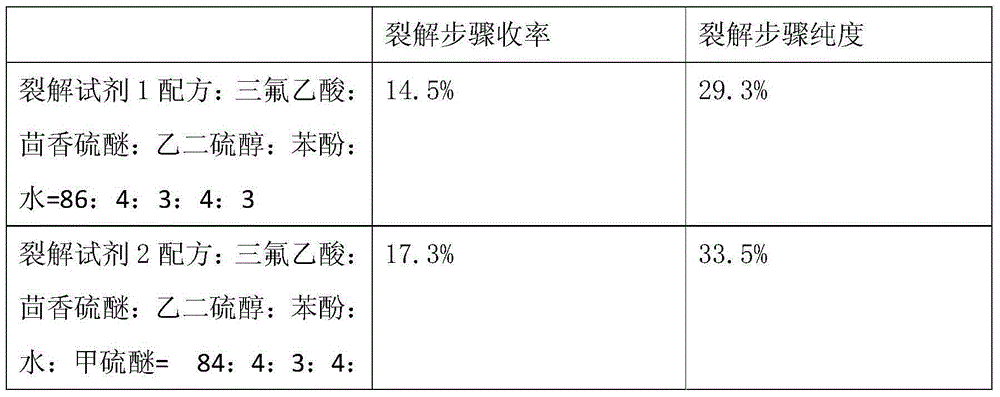

[0064] Prepare a lysate with a mass ratio (trifluoroacetic acid: thioanisole: ethanedithiol: phenol: water = 86:4:3:4:3) of 100 grams, and stir the prepared lysate evenly. Weigh 5% thymosin β4 peptide resin (5 g), add to the above lysate, and react for 120 minutes. After the reaction is completed, filter the above reaction solution with a sand core funnel, collect the filtrate, wash the filter cake with trifluoroacetic acid, and combine the filtrate. The filtrate was added to 1000 ml of glacial ether for precipitation, filtered with a sand core funnel, the filter cake was collected, washed with glacial ether, and put into a vacuum drying oven for vacuum drying to obtain thymosin β4 crude peptide. Weighed to get 2.55 grams of crude product, crude peptide weight yield: 96.2%, through HPLC detection, crude peptide purity: 29.3%

[0065] Purified by high performance liquid phase to obtain thymosin β4 fine ...

Embodiment 2

[0067] Thymosin β4 peptide resin was obtained by solid phase synthesis.

[0068] Prepare lysate, mass ratio (trifluoroacetic acid: thioanisole: ethanedithiol: phenol: water: methyl sulfide = 84: 4: 3: 4: 3: 2) 100 grams, stir the prepared lysate uniform. Weigh 5% thymosin β4 peptide resin (5 g), add to the above lysate, and react for 120 minutes. After the reaction is completed, filter the above reaction solution with a sand core funnel, collect the filtrate, wash the filter cake with trifluoroacetic acid, and combine the filtrate. The filtrate was added to 1000 ml of glacial ether for precipitation, filtered with a sand core funnel, the filter cake was collected, washed with glacial ether, and put into a vacuum drying oven for vacuum drying to obtain thymosin β4 crude peptide. Weighed 2.63 grams of crude product, crude peptide weight yield: 99.2%, through HPLC detection, crude peptide purity: 33.5%

[0069] Purified by high performance liquid phase to obtain thymosin β4 fi...

Embodiment 3

[0071] Thymosin β4 peptide resin was obtained by solid phase synthesis.

[0072] Configure lysate, mass ratio (trifluoroacetic acid: thioanisole: ethanedithiol: phenol: water: methyl sulfide: ammonium iodide = 83.5: 4: 3: 4: 3: 2: 0.5) 100 grams, will The prepared lysate was stirred evenly. Weigh 5% thymosin β4 peptide resin (5 g), add to the above lysate, and react for 120 minutes. After the reaction is completed, filter the above reaction solution with a sand core funnel, collect the filtrate, wash the filter cake with trifluoroacetic acid, and combine the filtrate. The filtrate was added to 1000 ml of glacial ether for precipitation, filtered with a sand core funnel, the filter cake was collected, washed with glacial ether, and put into a vacuum drying oven for vacuum drying to obtain thymosin β4 crude peptide. Weighed 2.88 grams of crude product, crude peptide weight yield: 108.7%, tested by HPLC, crude peptide purity: 43.5%

[0073] Purified by high performance liquid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com