A kind of target component and preparation method thereof

A target and component technology, applied in welding equipment, manufacturing tools, metal processing equipment, etc., can solve the problems of weak bonding and low processing temperature, and achieve the effect of good bonding and adhesion ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

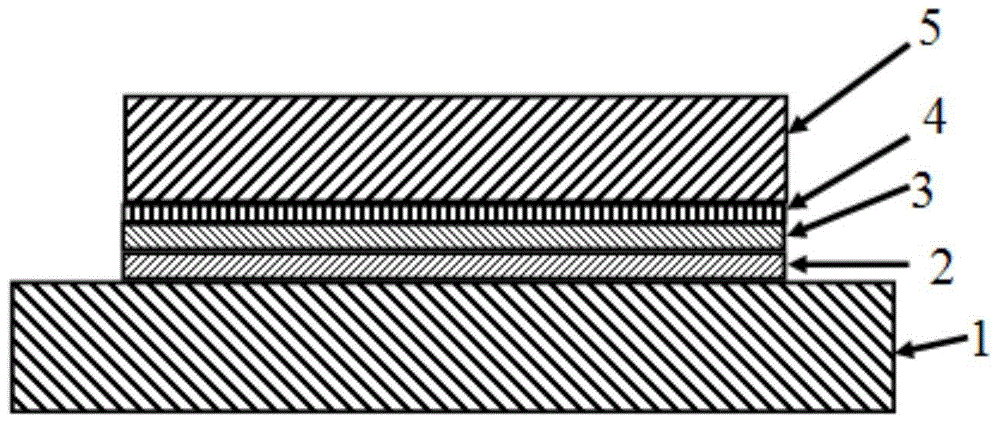

[0025] see figure 1 , the target assembly of the present invention includes a back plate 1 and a target material 5, the welding surface of the back plate 1 is provided with a back plate solder layer 2 with a low melting point, and the welding surface of the target material 5 is sequentially provided with plasma spraying from the inside to the outside The interface layer 4 and the target material solder layer 3 with a low melting point; the back plate solder layer 2 and the target material solder layer 3 are soldered softly.

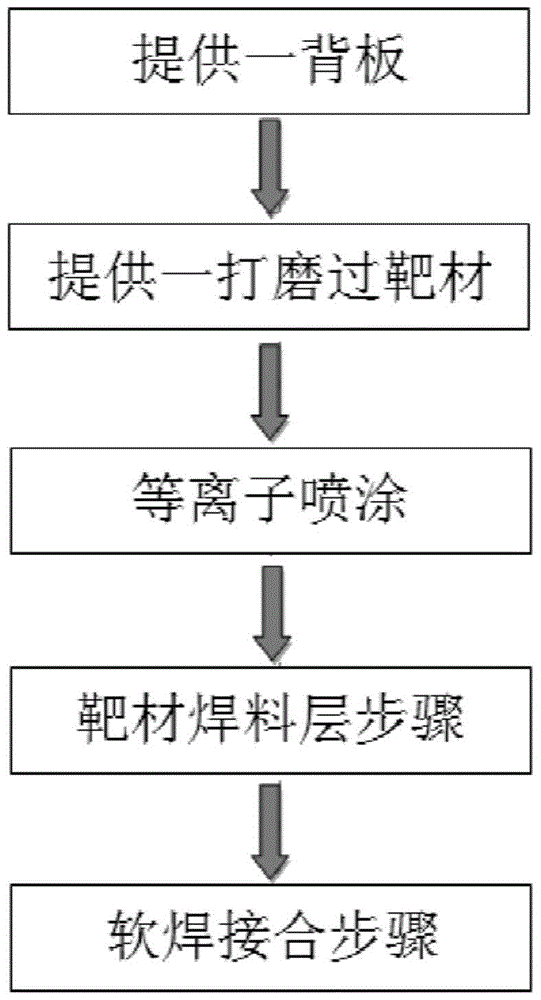

[0026] see figure 2 , the preparation method of the target assembly of the present invention includes the following steps:

[0027] (1) Coat the backplane solder layer 2 on the soldering surface of the backplane 1, and heat the backplane solder layer 2 into a molten state (the melting point of indium is 156.6° C.). The backplane solder layer 2 is composed of low melting point solder, the material of the backplane 1 is selected from copper, and the mate...

Embodiment 2

[0034] The difference from Embodiment 1 is that the material of the plasma sprayed interface layer 4 is aluminum oxide. The test result is: the tensile strength of the target assembly is 30-35kg / cm2.

Embodiment 3

[0036] The difference from Example 1 is that the welding surface of the target 5 is polished with 800 mesh sandpaper. The test result is: the tensile strength of the target assembly is 35-40kg / cm2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com