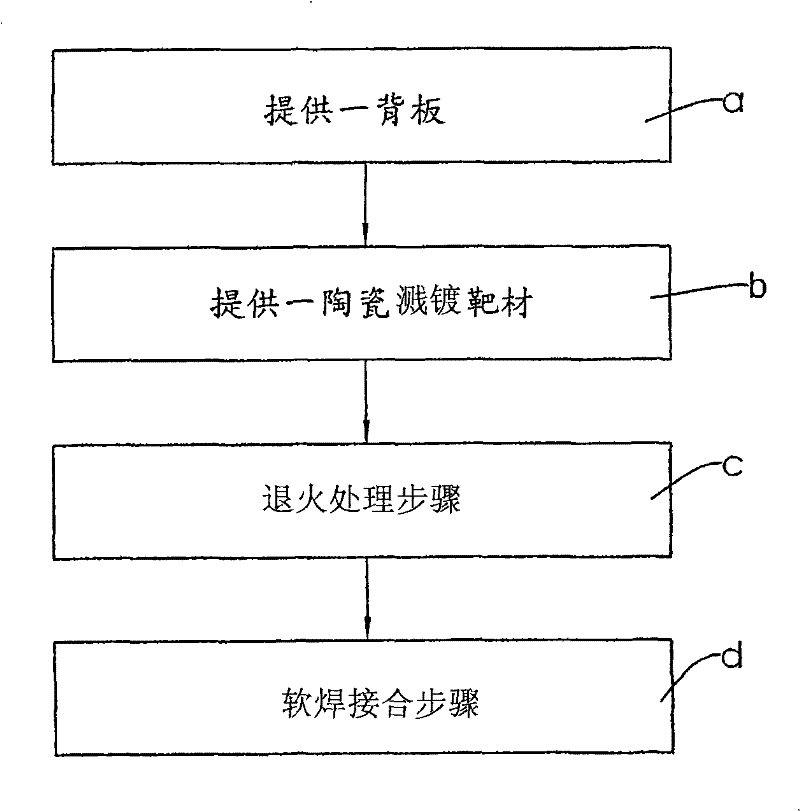

Ceramic sputtering target assembly and seaming method thereof

A technology for sputtering targets and ceramics, used in sputtering coating, ceramic layered products, chemical instruments and methods, etc., can solve problems such as abnormal growth of target grains, and achieve the effect of tight bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

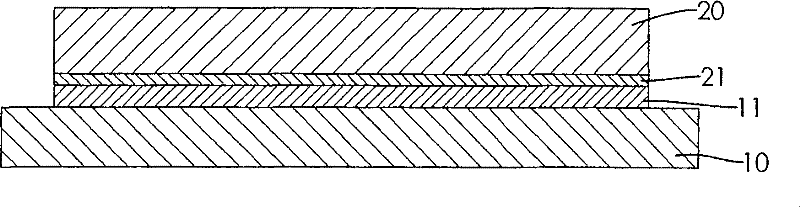

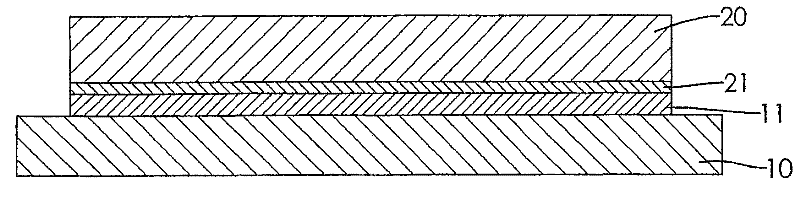

Embodiment 1

[0044] Coat one surface of the copper back plate with indium solder with low melting point to form a soft solder layer, and heat it to make it into a molten state (the melting point of indium is 156.6°C); vapor-deposit pure chromium material on the surface of the graphite target, and the thickness of the coating film is 1 μm; put the entire target into a vacuum heating furnace for temperature of 1200 ° C ~ 1500 ° C and pressure at 10 -5 to 10 -1The annealing treatment of torr, the treatment time is not more than 3 hours; after the target is annealed, the peeling test is carried out with cellophane tape to determine the peeling of the chromium-free coating, and then the target with chrome plating The surface of the target is treated with ultrasonic wet coating of indium solder, and finally the surface and the molten solder layer of the copper back plate are soldered and bonded, and the temperature is lowered to complete the welding of the target and the back plate. Follow-up a...

Embodiment 2

[0046] Coat one surface of the copper back plate with low-melting indium solder to form a soft solder layer, and heat it to make it into a molten state (the melting point of indium is 156.6°C); vapor-deposit pure chromium on the surface of the ITO (Indium Tin Oxide) target material, the coating thickness is 1 μm; the entire target is placed in a vacuum heating furnace at a temperature of 900°C to 1100°C and a pressure of 10 -5 to 10 -1 The annealing treatment of torr, the treatment time is not more than 3 hours; after the target is annealed, the peeling test (peeling test) is carried out with Sailufan tape to confirm that the chrome-free coating is peeled off, and then super-indium solder is carried out on the surface of the chrome-plated target. Sonic wet coating treatment, and finally the surface and the molten solder layer of the copper back plate are soldered and bonded, and the temperature is lowered to complete the welding of the target and the back plate. Follow-up and...

Embodiment 3

[0048] Coat one surface of the copper back plate with low-melting indium solder to form a soft solder layer, and heat it to make it into a molten state (the melting point of indium is 156.6°C); evaporate 95wt% of the surface of the ITO (Indium Tin Oxide) target Chromium-5wt% gold material, the coating thickness is 5μm; the whole target is placed in a vacuum heating furnace at a temperature of 900°C to 1100°C and a pressure of 10 -5 to 10 -1 The annealing treatment of torr, the treatment time is not more than 3 hours; after the target is annealed, the peeling test (peeling test) is carried out with Sailufan tape to determine the peeling of the chrome-gold plating layer, and then the surface of the target with chrome-gold plating is carried out Ultrasonic wet coating treatment of indium solder, and finally the surface and the molten solder layer of the copper back plate are soldered and bonded, and the temperature is lowered to complete the welding of the target and the back pla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com